Hollow fly ash brick and manufacturing method thereof

The technology of a fly ash brick and its production method is applied in the field of building materials, which can solve the problems of unreasonable formula of fly ash bricks, difficult matching of grooves and convex parts, heavy weight, etc., achieve good sound insulation effect, reduce weight, strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0024] Such as Figure 1 to Figure 5 As shown, the formula of the hollow fly ash brick of the present embodiment is composed of the following components: 4-9% of dry powdered calcium carbide sludge, 50-60% of stone powder, 25-30% of fly ash, 10-15% of sand, and 1-30% of water 8%.

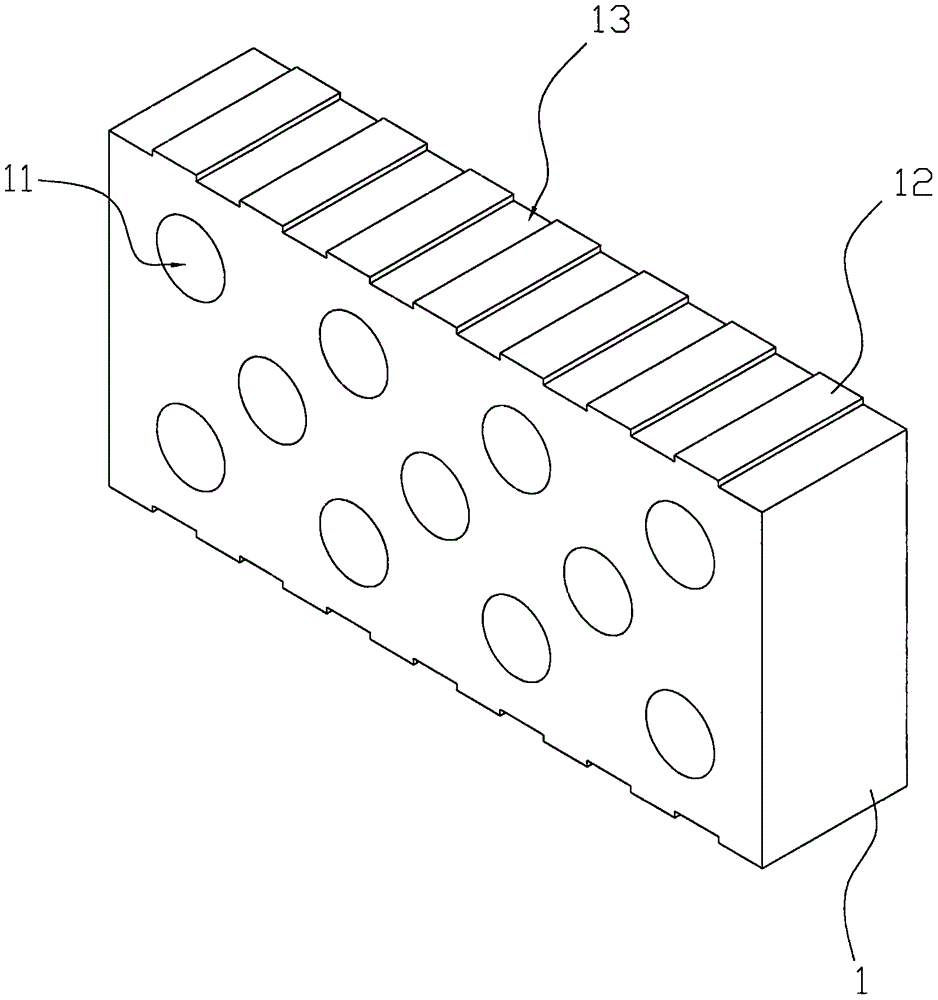

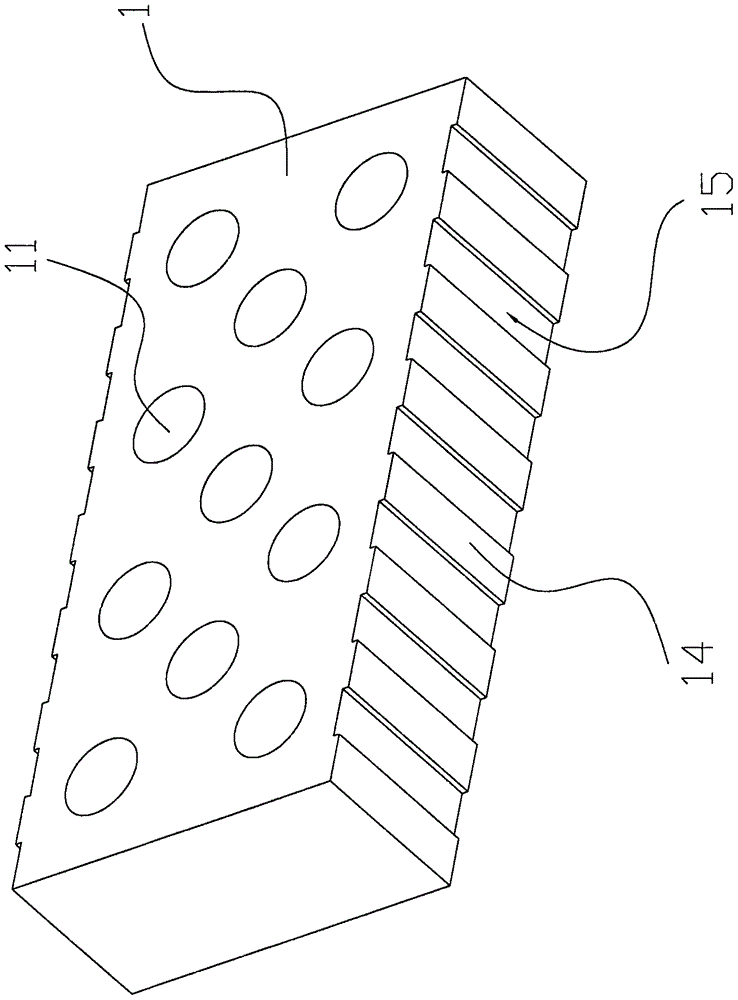

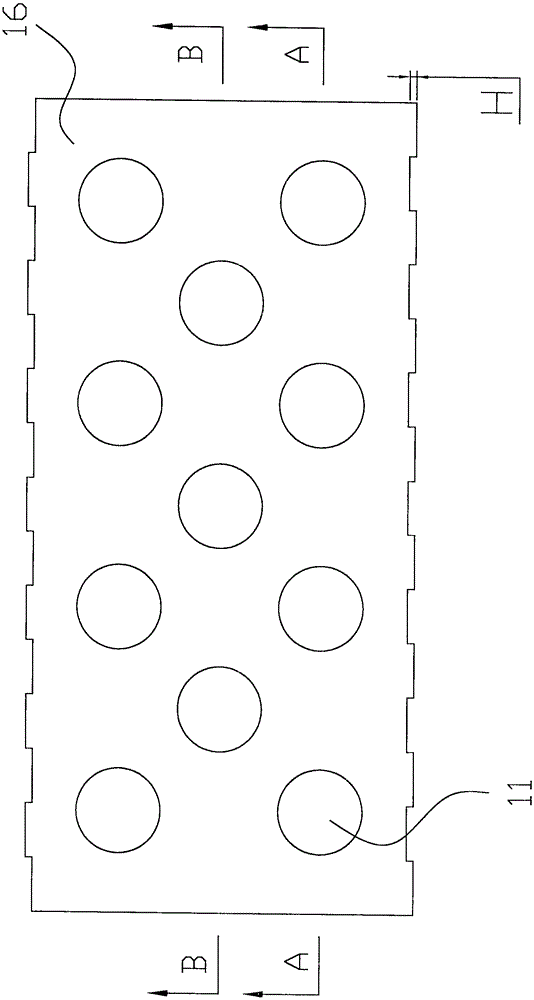

[0025] The hollow fly ash brick includes a brick body 1, on which a cavity 11 that can save material and reduce weight is distributed. On the left side of the brick body 1, there are 2 to 9 left Protrusions 12, between the left protrusions 12 is formed a left groove 13 in which the adhesive can be embedded when building a wall, and there are 2 to 9 right protrusions 14 distributed on the right side of the brick body 1 A right groove 15 is formed between the right convex part 14 and can also be embedded with a bonding agent when building a wall. The relative positi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com