Multilevel insulation protecting system for electrifying operation robot

A technology for working robots and protection systems, applied in the field of electric power, can solve problems such as short-circuit faults in power grids, unsuitable robots, hazards of robots and operators, and achieve the effect of improving insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It is easy to understand that, according to the technical solution of the present invention, those skilled in the art can imagine various implementations of the multi-level insulation protection system of the live working robot of the present invention without changing the essence of the present invention. Therefore, the following specific embodiments and drawings are only exemplary descriptions of the technical solution of the present invention, and should not be regarded as the entirety of the present invention or as a limitation or limitation on the technical solution of the present invention.

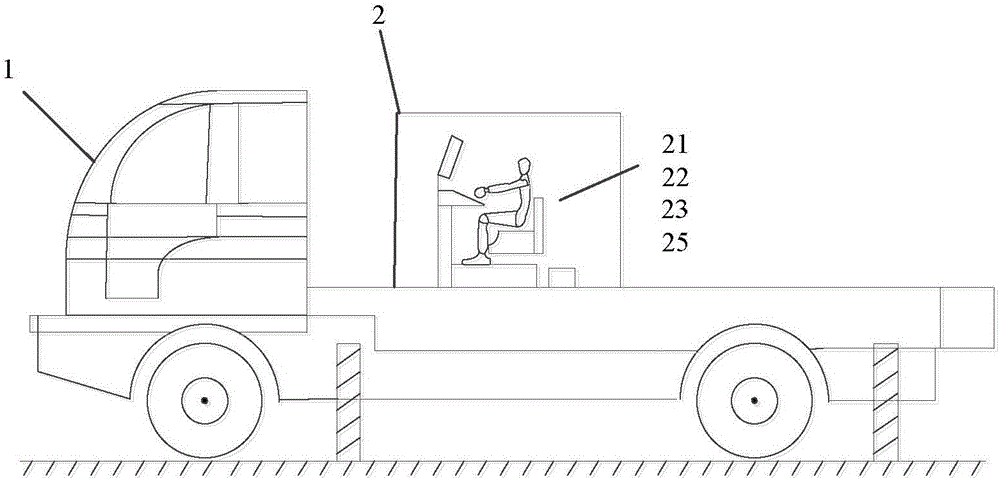

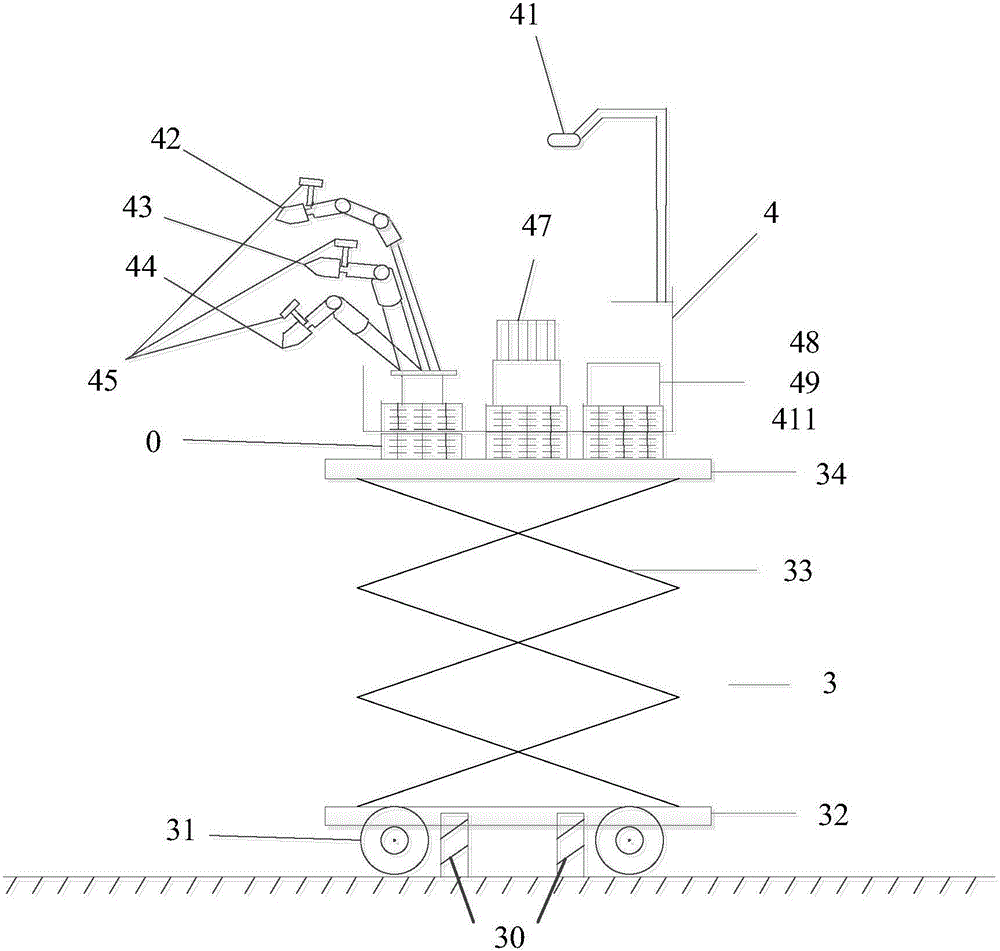

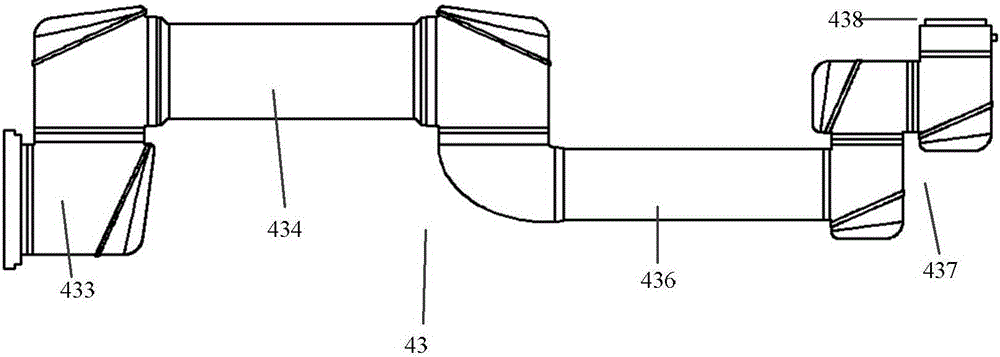

[0025] Combined with the accompanying drawings, the robot multi-level insulation protection system includes an isolation control room 2 that is completely isolated from the electric field of high-voltage equipment. The isolation control room 2 is equipped with an insulating shell and is located on a mobile vehicle 1; Fork lift 3, above scissor lift 3 is robot insulation robot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com