A method for preparing ag-agbr/al-mcm-41 composite functional material using natural attapulgite

An al-mcm-41, attapulgite technology, applied in the fields of photocatalysis and material chemistry, can solve the problems of cumbersome preparation process, high price, narrow catalyst source range, etc. The use of solvents and the effect of multiple firings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

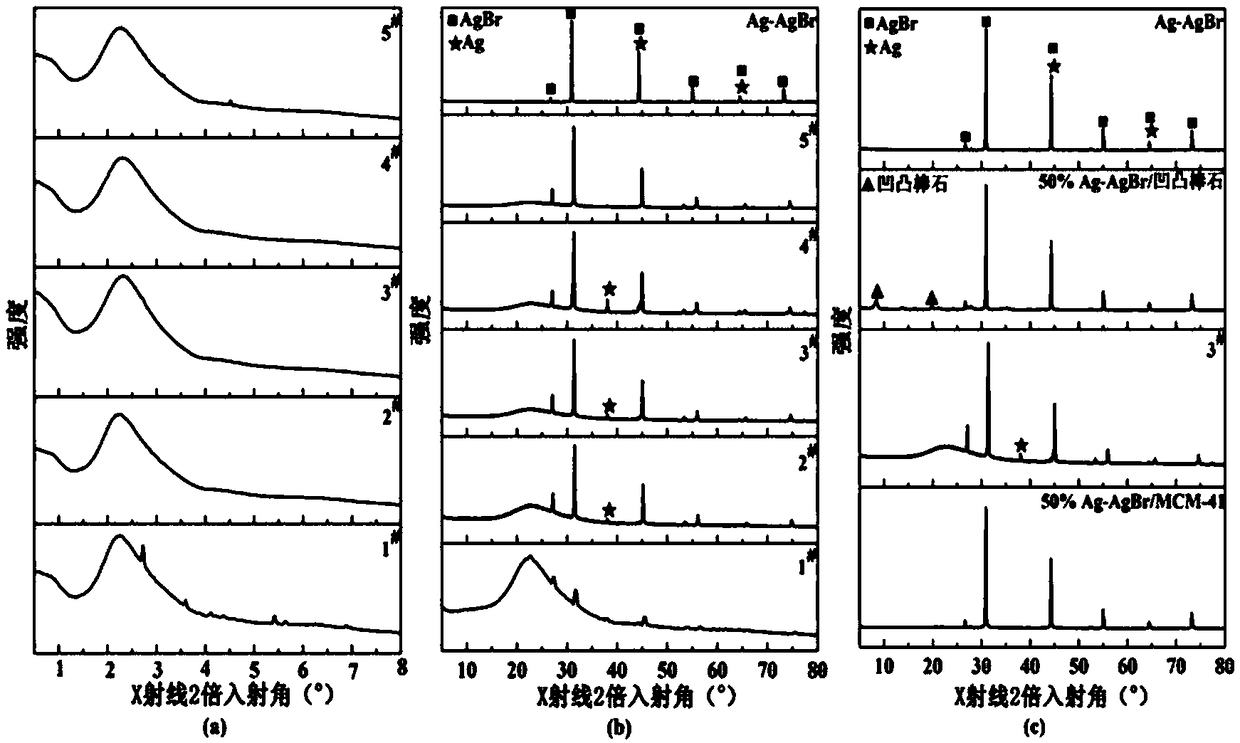

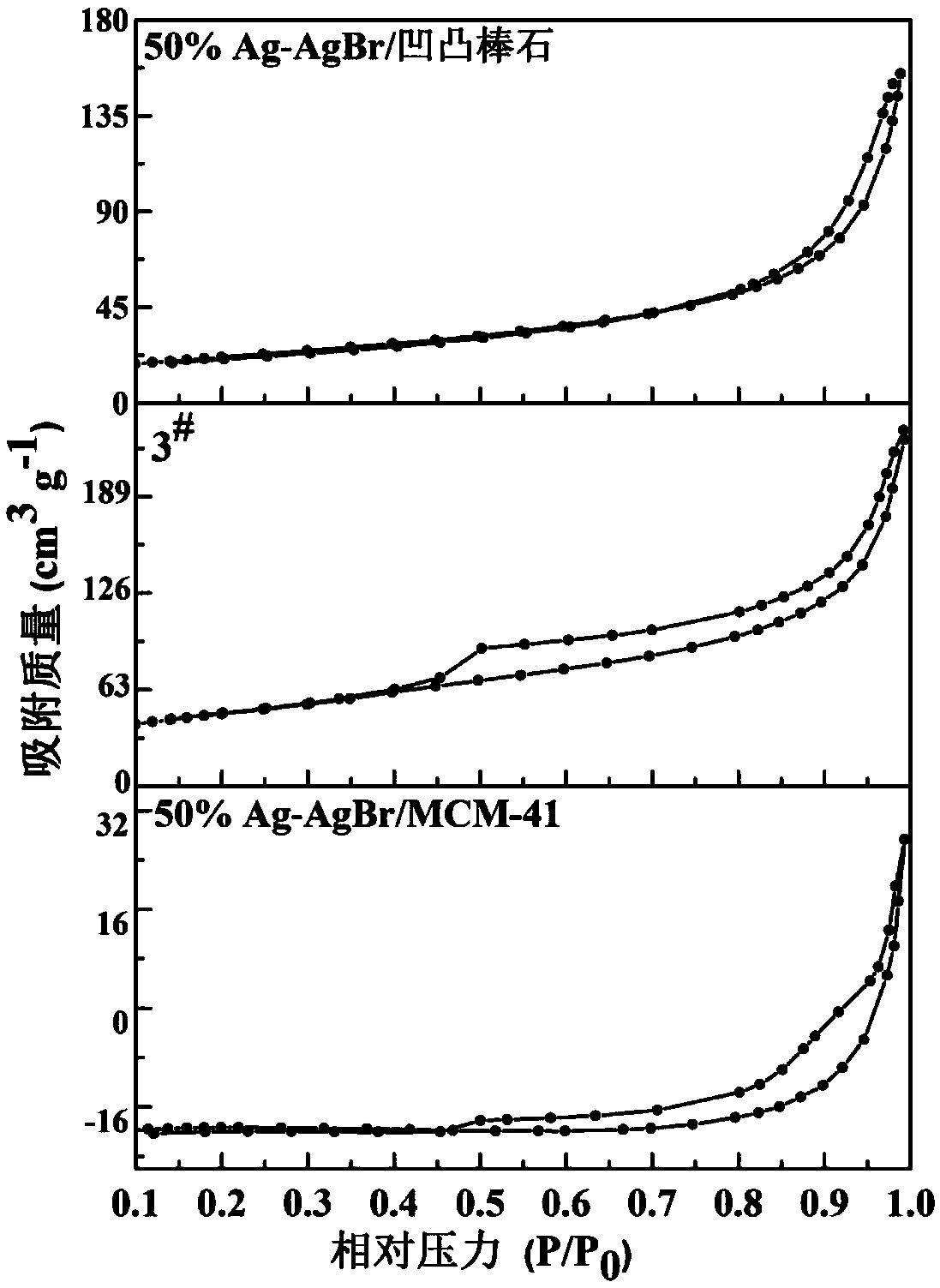

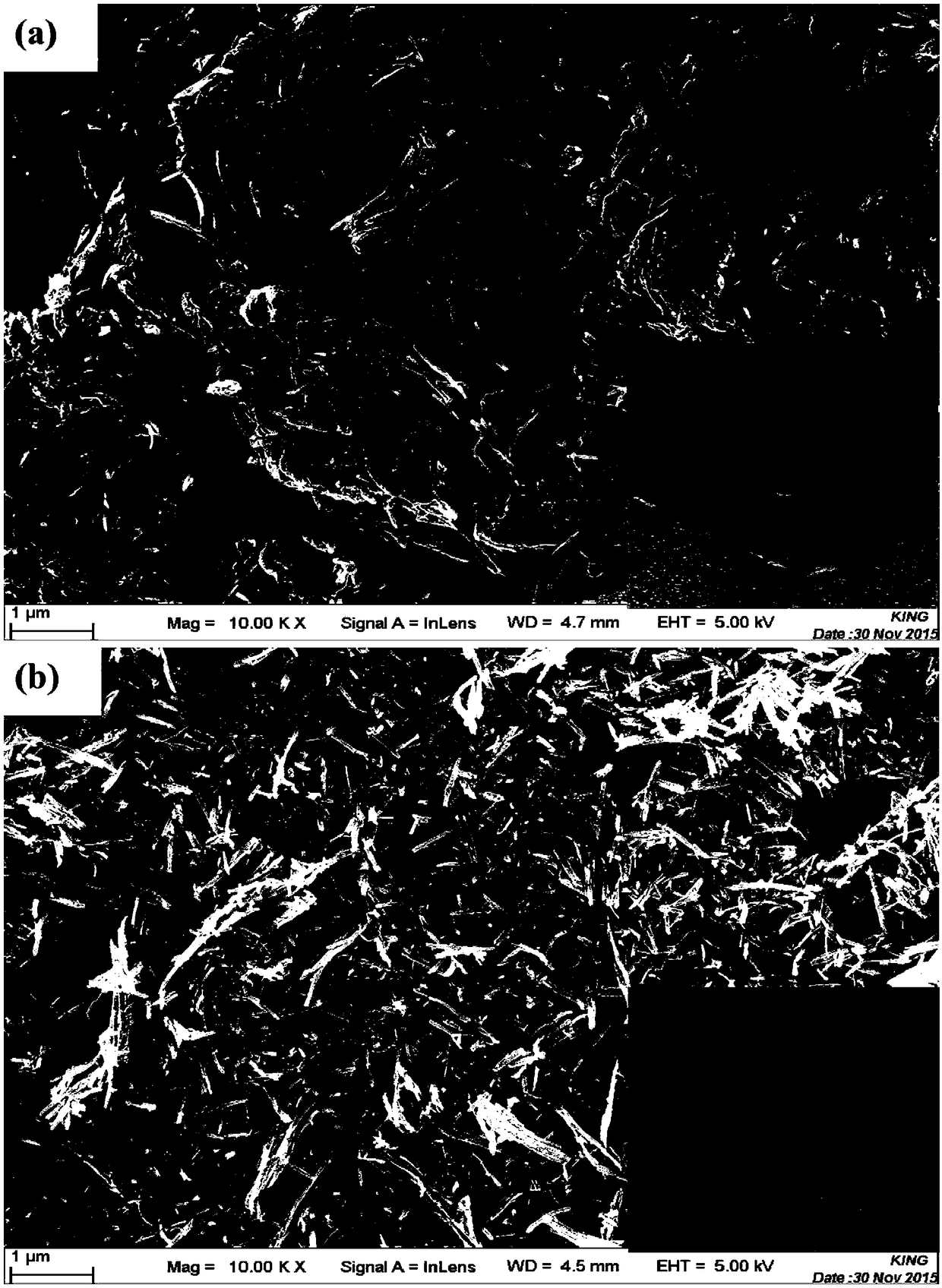

Embodiment 1

[0038] Weigh 20g of attapulgite clay, soak it with 80ml of 6mol / L HCl at 60°C for 12h, filter it with suction, wash it repeatedly with deionized water until neutral, and dry it at 80°C to obtain 18.2g of acidified attapulgite. Weigh 10g of acidified attapulgite, grind it with 15g of NaOH solid, mix well, and bake at 550°C for 4h. Transfer the roasted mixture to a stirred container, add 65ml of deionized water, and stir for 24 hours to fully dissolve the soluble aluminosilicate in it, and take the leachate from the upper layer as the silicon-aluminum source for later use.

[0039] Dissolve 0.3g of CTAB with 20ml of deionized water at 40°C for 1 hour, then add it to the silicon-aluminum source obtained above, and use 2mol / L of HNO 3 The pH=7 of the above solution was adjusted.

[0040] Weigh 0.1g of AgNO 3 , dissolved in 10ml of deionized water, and added dropwise to the above mixed solution, and stirred for 6h in the dark. The synthesized product was transferred to a high-pr...

Embodiment 2

[0042] Weigh 20g of attapulgite clay, soak it with 80ml of 6mol / L HCl at 60°C for 12h, filter it with suction, wash it repeatedly with deionized water until neutral, and dry it at 80°C to obtain 18.2g of acidified attapulgite. Weigh 10g of acidified attapulgite, grind it with 15g of NaOH solid, mix well, and bake at 550°C for 4h. Transfer the roasted mixture to a stirred container, add 65ml of deionized water, and stir for 24 hours to fully dissolve the soluble aluminosilicate in it, and take the leachate from the upper layer as the silicon-aluminum source for later use.

[0043] Dissolve 0.7g of CTAB with 20ml of deionized water at 40°C for 1 hour, then add it to the silicon-aluminum source obtained above, and use 2mol / L of HNO 3 The pH=7 of the above solution was adjusted.

[0044] Weigh 0.3g of AgNO 3 , dissolved in 10ml of deionized water, and added dropwise to the above mixed solution, and stirred for 6h in the dark. The synthesized product was transferred to a high-pr...

Embodiment 3

[0046] Weigh 20g of attapulgite clay, soak it with 80ml of 6mol / L HCl at 60°C for 12h, filter it with suction, wash it repeatedly with deionized water until neutral, and dry it at 80°C to obtain 18.2g of acidified attapulgite. Weigh 10g of acidified attapulgite, grind it with 15g of NaOH solid, mix well, and bake at 550°C for 4h. Transfer the roasted mixture to a stirred container, add 65ml of deionized water, and stir for 24 hours to fully dissolve the soluble aluminosilicate in it, and take the leachate from the upper layer as the silicon-aluminum source for later use.

[0047] Dissolve 1.1 g of CTAB with 20 ml of deionized water at 40°C for 1 h, then add it to the silicon-aluminum source obtained above, and add 2 mol / L of HNO 3 The pH=7 of the above solution was adjusted.

[0048] Weigh 0.5g of AgNO 3 , dissolved in 10ml of deionized water, and added dropwise to the above mixed solution, and stirred for 6h in the dark. The synthesized product was transferred to a high-pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com