Oil-water separation and sewage discharge device for transformer oil storage pool

A sewage device, oil-water separation technology, applied in the direction of separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of increasing the work intensity of operation and maintenance personnel, increasing the cost of equipment operation and maintenance, and unable to discharge accumulated water, so as to reduce inspections The effect of reducing workload, eliminating potential safety hazards, and reducing inspection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

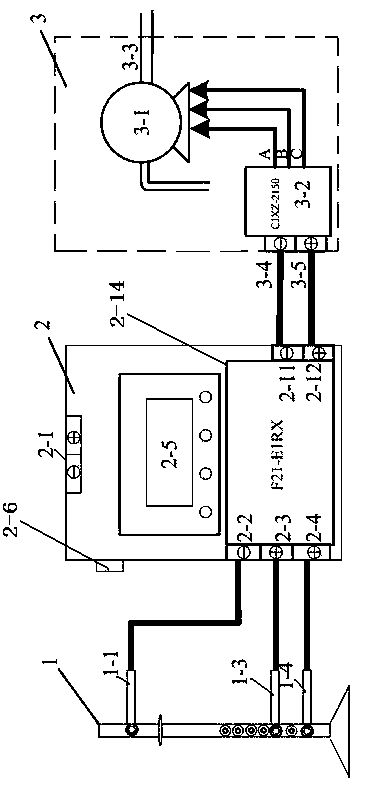

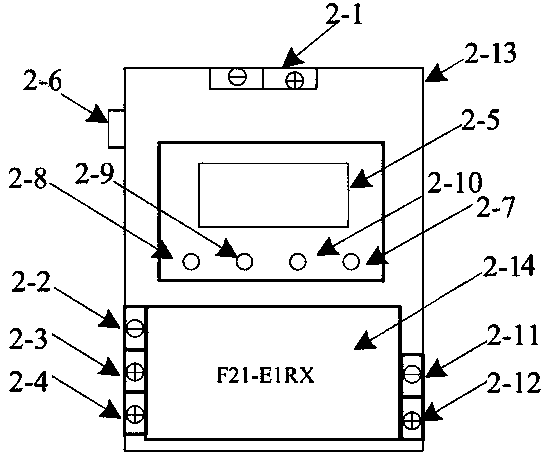

[0019] Embodiment: A kind of oil-water separation and sewage discharge device of transformer oil storage pool (see figure 1 ), which consists of three parts: oil storage tank water level judging device 1, integrated control device 2 and sewage discharge device 3.

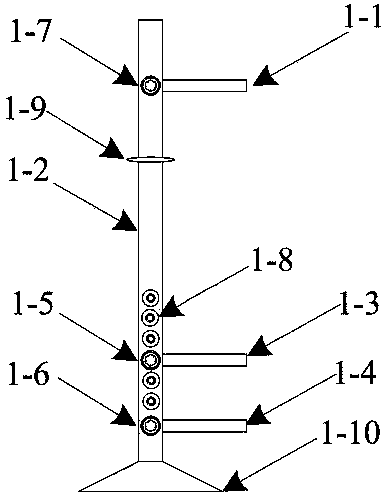

[0020] Oil storage tank water level judging device 1 (see figure 2 ) includes a support rod base 1-10, an adjustable support rod 1-2 is connected to the support rod base 1-10, and the upper part of the adjustable support rod 1-2 is connected to a zero potential contact piece 1- 1. There is a fastening ring 1-9 under the zero-potential contact piece 1-1 on the adjustable support rod 1-2, which is used to fix the adjustable support rod 1-2 on the wall of the storage tank, and the adjustable support rod 1-2 There are several countersunk holes 1-8 for adjusting the water level evenly distributed in the lower part, and the middle and lower part of the adjustable support rod 1-2 is connected to the sewage pump starting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com