Self-heating paster

A self-heating and film-sticking technology, applied in the field of skin care, can solve the problems of low safety, inconvenient use, low absorption efficiency of solid nutrients, etc., and achieves the effect of protecting the skin, being easy to manufacture, and avoiding low-temperature burns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Embodiment 1 Preparation of a self-heating film

[0069] 1) Preparation of functional composition body:

[0070]

[0071] a. Take a clean container, pre-mix the glycerin and xanthan gum of phase A evenly, add it into purified water, then add the remaining raw materials of phase A, heat to 80-85°C, stir and dissolve completely.

[0072] b. Cool down to 40-45°C, add phase B raw materials, then add pre-mixed phase C raw materials, continue to stir and cool down.

[0073] c. Cool down to 30-35°C, stop stirring, and it will be a body sample of the functional composition.

[0074] 2) The preparation method of the self-heating film can be carried out as follows:

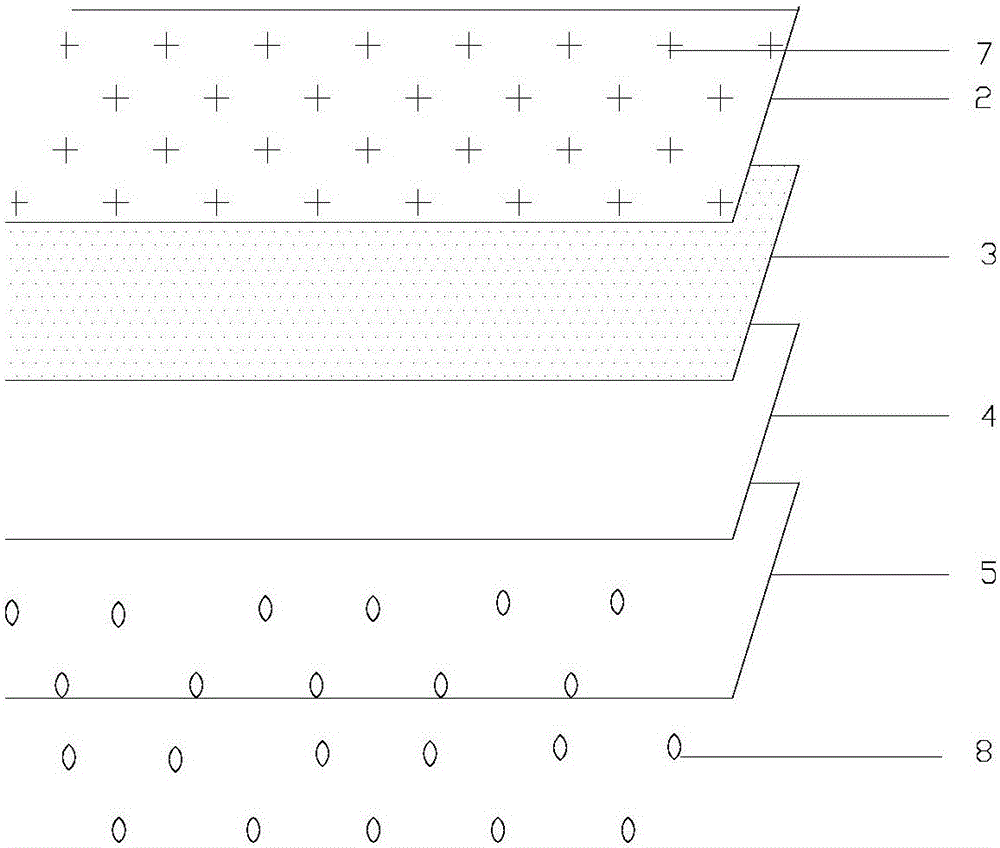

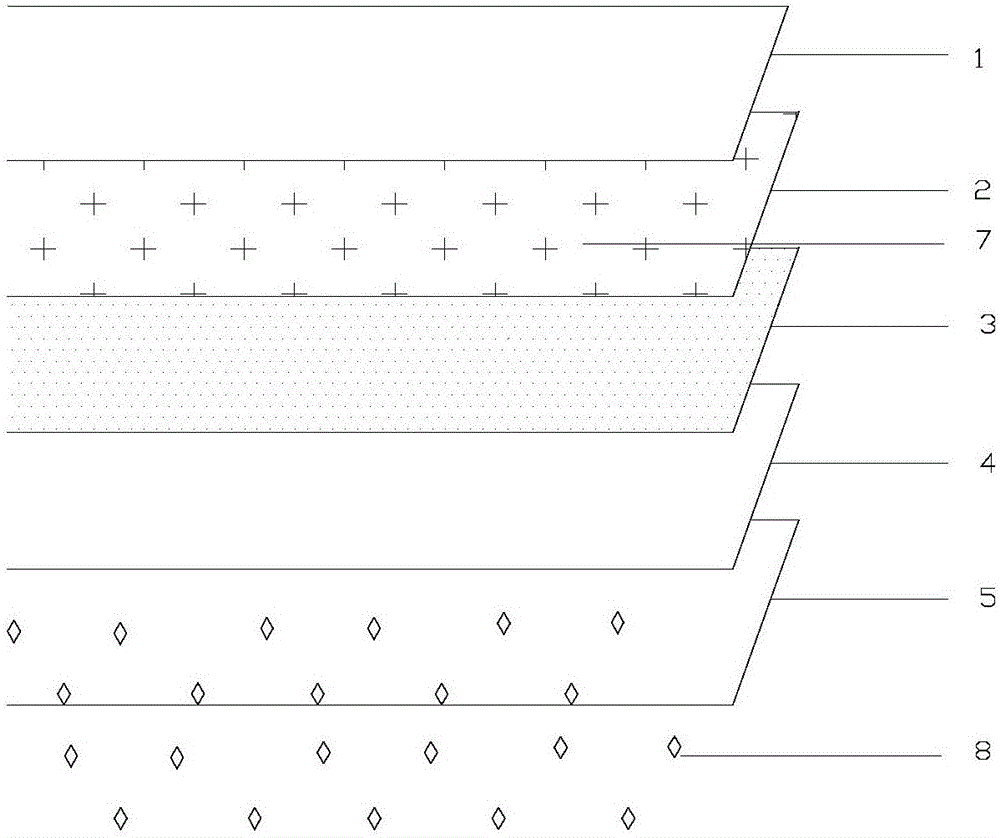

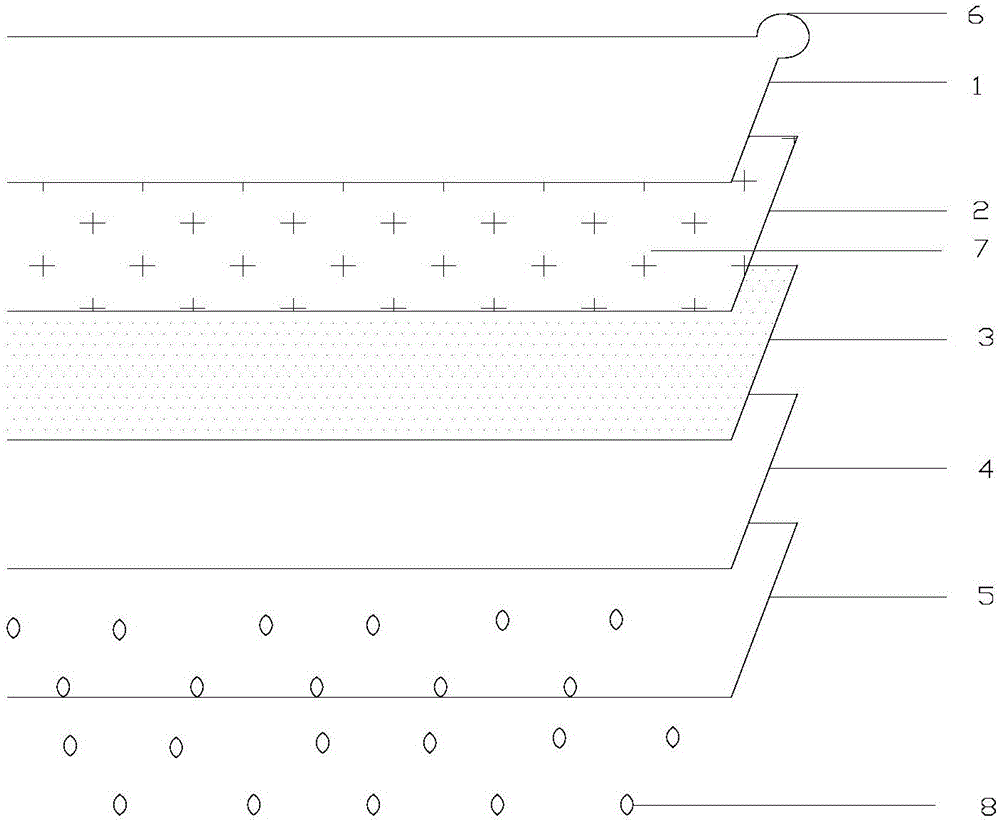

[0075] Firstly, the water-proof protective layer 4 and the liquid-absorbent layer 5 are sewn or glued, and the water-proof protective layer 4 faces upward. In an oxygen-free environment, stir the self-heating layer material 3 evenly, put it on the water-proof protective layer 4, and then put the air-permeable l...

Embodiment 2

[0077] Embodiment 2 self-heating film

[0078]

Embodiment 3

[0079] Example 3 Experiment on the use effect of self-heating film

[0080] The self-heating eye mask and functional composition prepared in the above-mentioned Example 1 were used for human testing, and 50 women aged 30-50 were selected for the test and randomly divided into two groups.

[0081] The control group directly soaked the non-woven fabric with the functional composition. Take out the soaked non-woven fabric and let it dry. During the test, the subjects were asked to generate heat through a commercially available hot water bag or a winter heating sheet product, and apply heat to the eye area through the non-woven fabric containing the functional composition.

[0082] The experimental group used the self-heating eye mask prepared in Example 1.

[0083] Ask them to use the corresponding samples according to the aforementioned method, once every 2 days, 15 minutes each time, for a total of two weeks. At the same time, the sleep time of the subjects is controlled, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com