A multifunctional steam sink

A multi-functional, steam technology, applied in the direction of steam cooking utensils, household cleaning devices, tableware washing machines/rinsing machines, etc., can solve the problems of low cooking efficiency, and achieve low cooking efficiency, practicality and economy Excellent performance and the effect of increasing the available space in the kitchen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

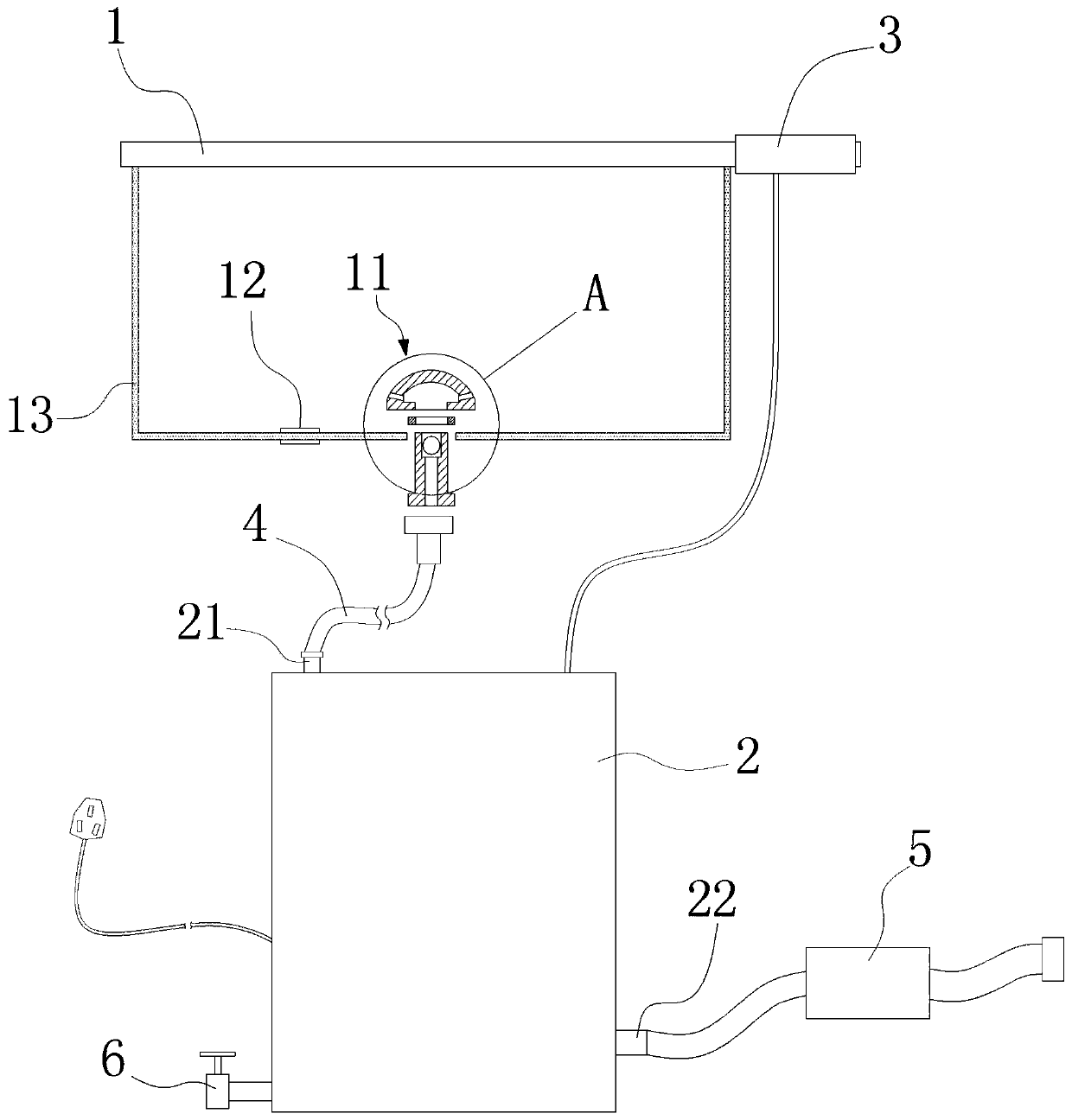

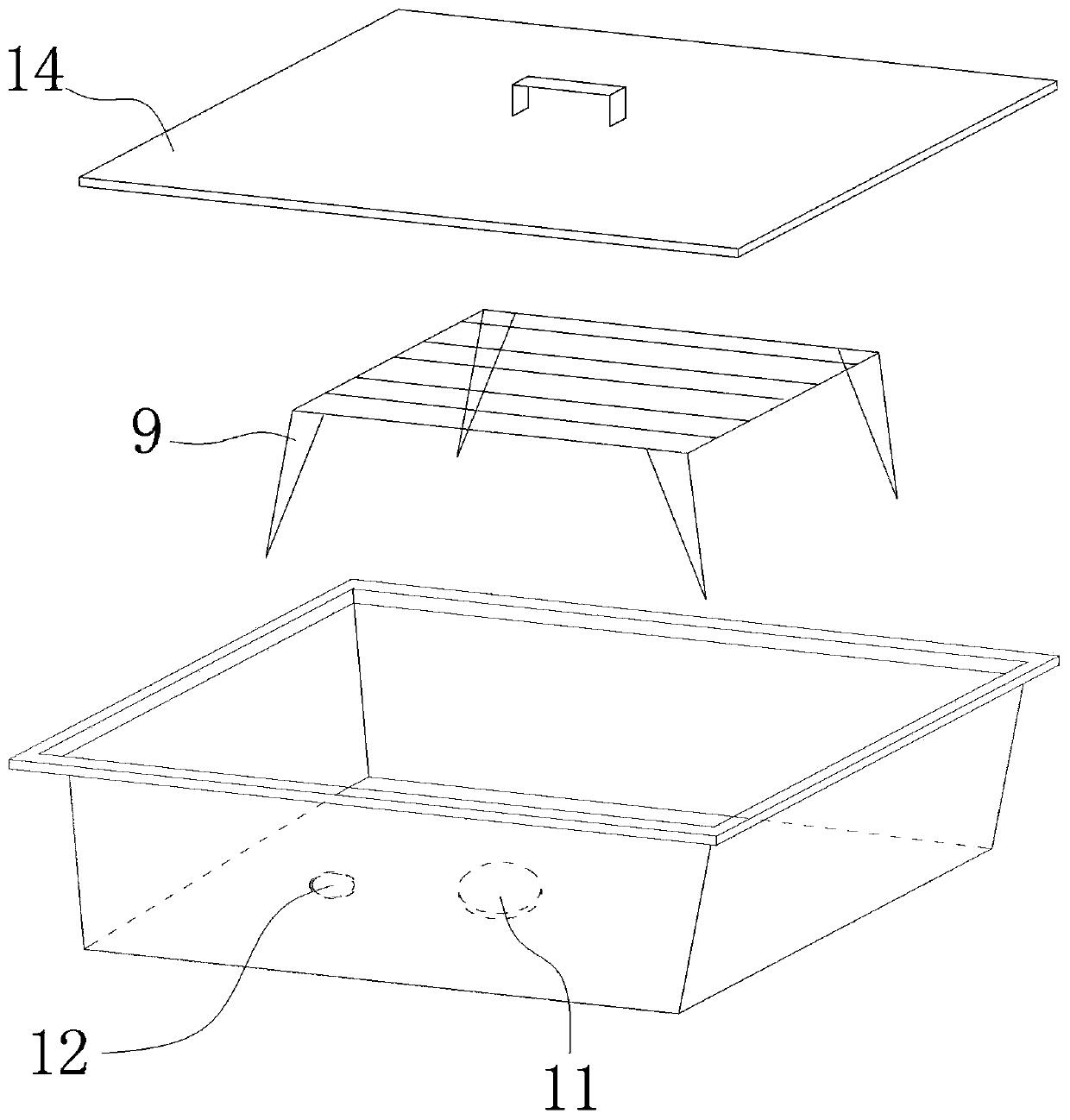

[0028] See attached Figure 1 to 3 , A multifunctional steam water tank, comprising: a tank body 1, a cover plate 14 covering the opening of the tank body 1, a steam generator 2, a high-temperature steam pipe 4 and a controller 3. The bottom of the tank body 1 is provided with a drain 12 and a steam port 10, the steam port 10 is provided with a steam spray head mechanism 11; the steam generator 2 is located below the tank body, which has a steam output connector 21 and a water inlet connector 22, the steam output connector 21 through the high temperature steam pipe 4 is connected to the steam spray head mechanism 11, and the water inlet connector 22 is connected to a water source; the controller 3 has an operation panel which is connected to and controls the steam generator 2. In specific implementation, the tank body 1 and the steam generator 2 may be placed separately, or the tank body 1 and the steam generator 2 may be integrated. The steam generator 2 may also be placed acc...

Embodiment 2

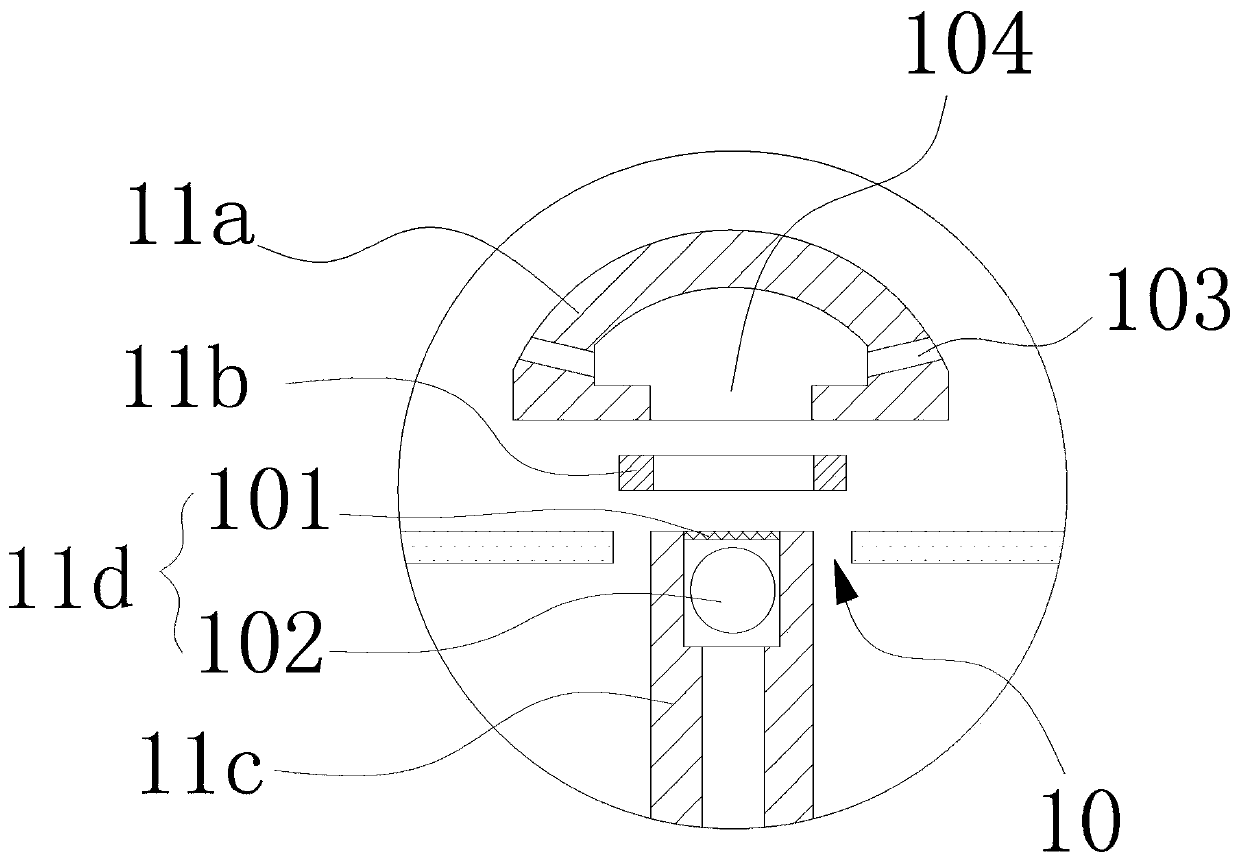

[0037] See attached Figure 4 , A multifunctional steam water tank, comprising: two tank bodies 1A, 1B, a cover plate 14 covering the opening of the tank body, a steam generator 2, a high-temperature steam pipe 4 and a controller 5, and the bottom of the tank bodies 1A, 1B A drain port 12 and a steam port 10 are respectively provided. The steam port 10 is provided with a steam nozzle mechanism 11, which includes a nozzle cap 11a, a rubber gasket 11b, a piston check valve 11c and a nozzle seat 11d. 11d penetrates the steam port 10, which has through upper and lower end openings, the upper end opening is provided with the piston one-way valve 11c, the nozzle cap 11a is placed on the upper end opening of the nozzle seat 11d, on which is provided A plurality of vent holes 103, which have a channel 104 connecting the upper end of the nozzle holder 11d and the vent hole 103, the rubber gasket 11b is sleeved on the nozzle holder 11d; the steam generator 2 has a steam output connector 2...

Embodiment 3

[0039] See attached Figure 5 , A multifunctional steam water tank, comprising: a main tank body 1A and an auxiliary tank body 1B, a cover plate 14 covering the openings of the tank bodies 1A and 1B, a steam generator 2, a high temperature steam pipe 4 and a controller 3 , The bottom of the main tank body 1A is provided with a drainage port 12 and a steam port 10. The steam port 10 is provided with a steam nozzle mechanism 11, the steam nozzle mechanism 11 includes a nozzle cap 11a, a rubber gasket 11b, a piston check valve 11c and a nozzle seat 11d, the nozzle seat 11d penetrates the steam port 10, and has a through upper and lower end opening, the upper end opening is provided with the piston check valve 11c, and the nozzle cap 11a is placed on the upper end opening of the nozzle seat 11d , There are a number of vent holes 103 on it, and the inside has a channel 104 connecting the upper end of the nozzle holder 11d and the vent hole 103, the rubber gasket 11b is sleeved on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com