Preparation method of konjak tofu

A technology of konjac tofu and konjac, which is applied in the field of konjac tofu preparation, and can solve problems such as astringent taste, uneven elasticity of konjac tofu, and no further improvement in quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Adopt this method to prepare konjac tofu, finish by following nine big steps.

[0028] (1) Cleaning: Wash the complete and fresh konjac tubers.

[0029] ⑵Steaming: Put the washed konjac tubers in the bamboo steamer, and then set the bamboo steamer on the steamer. The shelf in the bamboo steamer is not in contact with water. Steam directly with steam for 2 minutes.

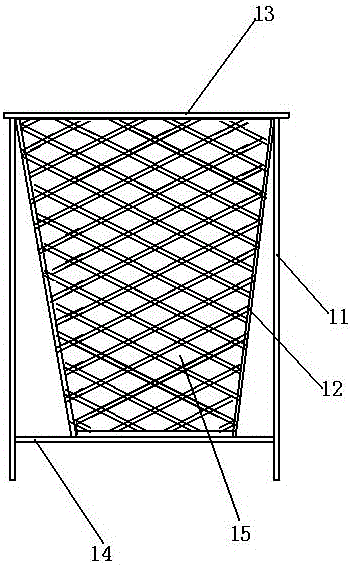

[0030] Described bamboo-wood retort is made by wooden barrel 11, bamboo basket 12 and wooden cover 13; Described wooden barrel 11 is cylindrical wooden barrel, and wooden barrel wall is solid wood wall, does not have slit or hole on the wall, and wooden barrel has no bottom, The lower position of the wooden barrel 11 is provided with a shelf 14, and the shelf 14 has a certain distance from the bottom edge of the wooden barrel 11; the bamboo basket 12 is a conical cylindrical bamboo basket, and the outer diameter of the top of the conical barrel is equal to the inner diameter of the wooden barrel. The wall ...

Embodiment 2

[0041] Adopt this method to prepare konjac tofu, finish by following nine big steps.

[0042] (1) Cleaning: Wash the complete and fresh konjac tubers.

[0043] (2) steaming: the konjac tuber after cleaning is placed in the bamboo steamer, then the bamboo steamer is erected on the steamer, the shelf 14 in the bamboo steamer does not contact with water, utilizes the water boiled in the steamer Steam directly with steam for 3 minutes.

[0044] (3) Cutting into pieces: put the steamed konjac tubers into cold water to cool quickly, then remove the outer skin and cut into small pieces to obtain konjac pieces.

[0045] (4) water mill: 100kg konjac block is put into 300kg normal temperature clear water, repeatedly carries out water mill 30 minutes with grinding tank, crosses 50 mesh sieves and separates pulp residue, takes liquid and obtains water mill konjac pulp.

[0046] (5) Alkali milling: 100kg water-milled konjac pulp was put into 220kg normal temperature alkaline water, and c...

Embodiment 3

[0052] Adopt this method to prepare konjac tofu, finish by following nine big steps.

[0053] (1) Cleaning: Wash the complete and fresh konjac tubers.

[0054] (2) steaming: the konjac tuber after cleaning is placed in the bamboo steamer, then the bamboo steamer is erected on the steamer, the shelf 14 in the bamboo steamer does not contact with water, utilizes the water boiled in the steamer Steam directly with steam for 5 minutes.

[0055] (3) Cutting into pieces: put the steamed konjac tubers into cold water to cool quickly, then remove the outer skin and cut into small pieces to obtain konjac pieces.

[0056] (4) water mill: 100kg konjac block is put into 350kg normal temperature clear water, repeatedly carries out water mill 35 minutes with grinding tank, crosses 50 mesh sieves and separates pulp residue, takes liquid and obtains water mill konjac pulp.

[0057] (5) Alkali milling: 100kg of water-milled konjac pulp is put into 260kg of normal-temperature alkaline water, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com