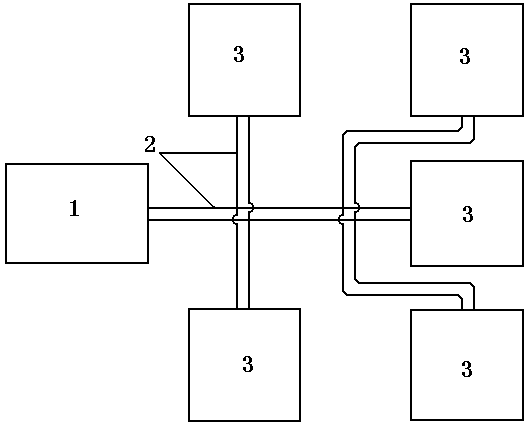

A central heating oil fryer with heat conduction oil connected to multiple boilers

A technology of central heating and heat transfer oil, which is applied in the direction of oil/fat baking, etc., can solve the problems of low heat energy utilization and production efficiency of gas fryers, and achieve the effects of improving frying efficiency, uniform heating, and fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

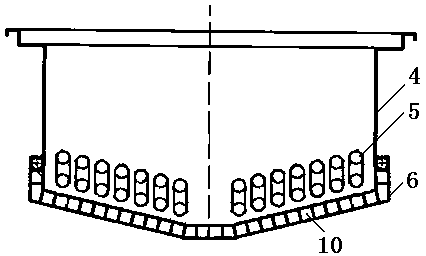

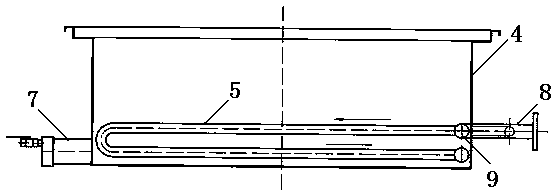

[0017] Embodiment 1: Fill frying edible oil into the pot body 4 to a reasonable height above the inner heating coil 5 .

Embodiment 2

[0018] Embodiment 2: Set the working temperature of fried cooking oil in the controller and switch on the power supply of the control components.

Embodiment 3

[0019] Embodiment 3: The controller instructs the solenoid valve to open according to the temperature information of the fried edible oil from the temperature sensor, and the high-temperature heat transfer oil of the heat transfer oil heat source device 1 is simultaneously heated through the heat supply pipe of the circulation pipe 2 and the connection pipe 8 of the circulation pipe. The end joint 9 is transported to the inner heat transfer coil 5 and the outer heat transfer coil 6 to transfer heat to the fried edible oil, and the heat transfer oil after heat transfer returns to the heat transfer source device 1 through the return end joint 9 and the return pipe of the circulation pipe 2 Circulation heating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com