Composite lithium battery and preparation method thereof

A lithium-composite battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor cycle performance, easy loss of active materials, and low safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1. Accurately weigh elemental sulfur and LFPO (lithium iron phosphate) cathode materials according to the stoichiometric ratio, wherein sulfur accounts for 30%. In step 2, the weighed material is put into grinding for half an hour to obtain a mixed material sample, which is used as the positive electrode active material material of the new composite lithium battery. In step 3, the positive electrode active material is made into the positive electrode of the battery, and a composite lithium battery is formed with the negative electrode, separator and electrolyte.

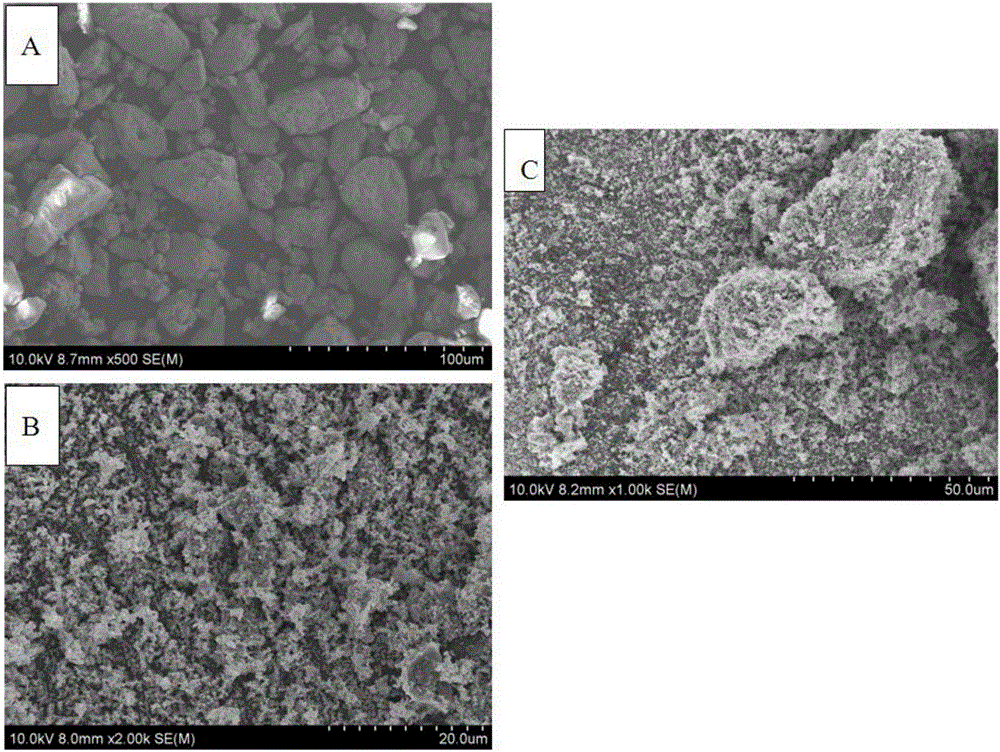

[0034] Elemental sulfur ( figure 1 A in A), LFPO cathode material ( figure 1 B in B) and the mixed cathode material obtained by this example ( figure 1 The SEM (scanning electron microscope) image of C) is shown in figure 1 As shown, it can be seen from the figure that the morphology of the elemental sulfur material itself is basically not damaged, and the LFPO cathode material particles are attached t...

Embodiment 2

[0038] Step 1. Accurately weigh elemental sulfur and LFPO cathode material according to the stoichiometric ratio, wherein sulfur accounts for 20%. In step 2, the weighed material is put into grinding for half an hour to obtain a mixed material sample, which is used as the positive electrode active material material of the new composite lithium battery. In step 3, the positive electrode active material is made into the positive electrode of the battery, and a composite lithium battery is formed with the negative electrode, separator and electrolyte.

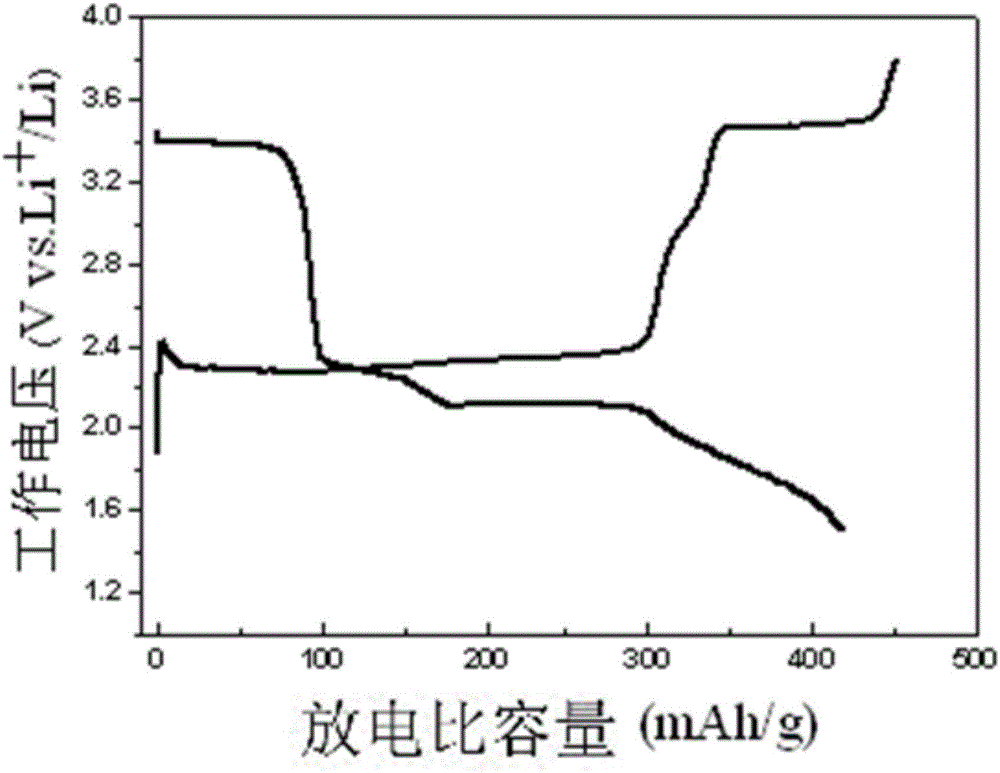

[0039] The charge-discharge curve of the novel composite lithium battery obtained by this embodiment is as follows: Figure 4 As shown, the charging and discharging platform of the elemental sulfur cathode material and the charging and discharging platform of the LFPO cathode material can be clearly distinguished from the figure. The charge specific capacity is 320.2mAh / g, the discharge specific capacity is 336.8mAh / g, and the eff...

Embodiment 3

[0041] Step 1. Accurately weigh lithium sulfide and LFPO cathode materials according to the stoichiometric ratio, wherein lithium sulfide accounts for 30%. In step 2, the weighed material is put into grinding for half an hour to obtain a mixed material sample, which is used as the positive electrode active material material of the new composite lithium battery. In step 3, the positive electrode active material is made into the positive electrode of the battery, and a composite lithium battery is formed with the negative electrode, separator and electrolyte.

[0042] The charge-discharge curve of the novel composite lithium battery obtained by this embodiment is as follows: Figure 5 As shown, the charge specific capacity is 471.9mAh / g, the discharge specific capacity is 439.4mAh / g, and the efficiency is 93.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com