LED service life prediction method under actual operation environment

A technology of actual operation and life prediction, applied in the direction of lamps and lanterns testing, etc., can solve the problems of ignoring the life difference of samples, unable to read reliability information, etc., and achieve the effect of guiding LED heat dissipation and system design, improving life and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The technical solution of the invention will be described in detail below in conjunction with the accompanying drawings.

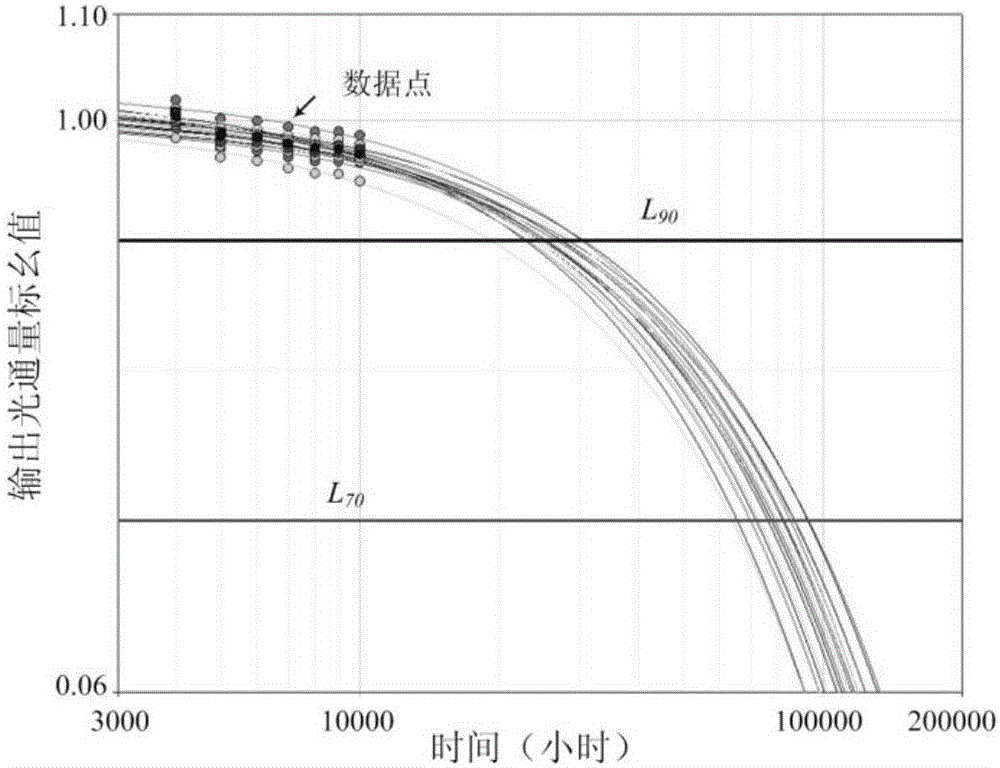

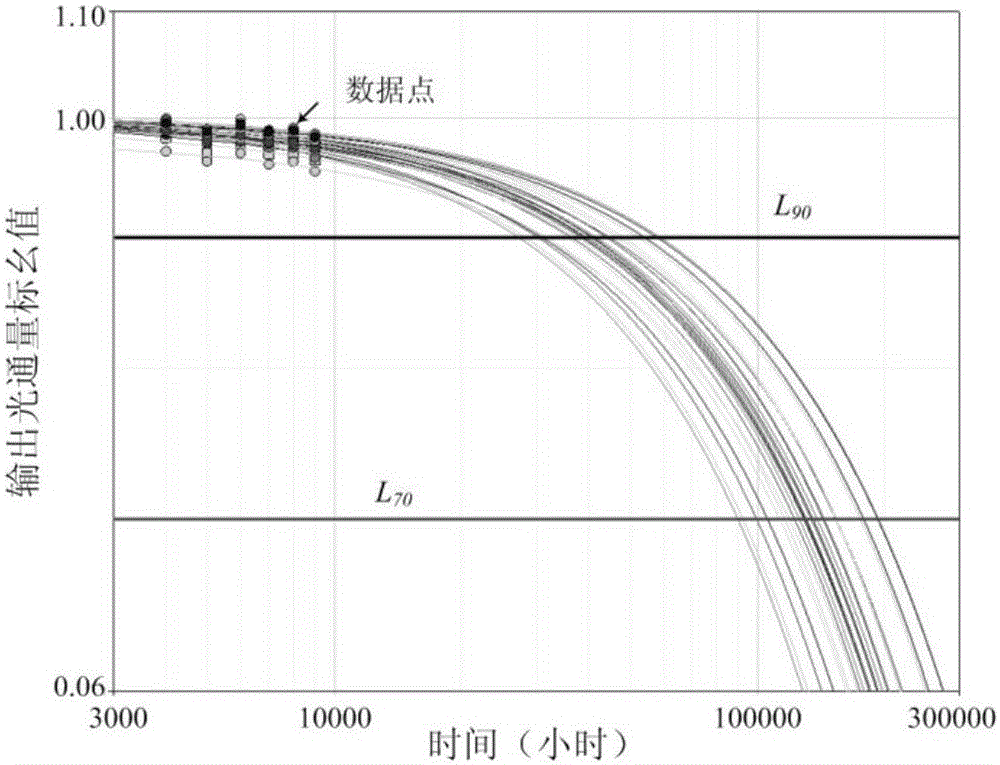

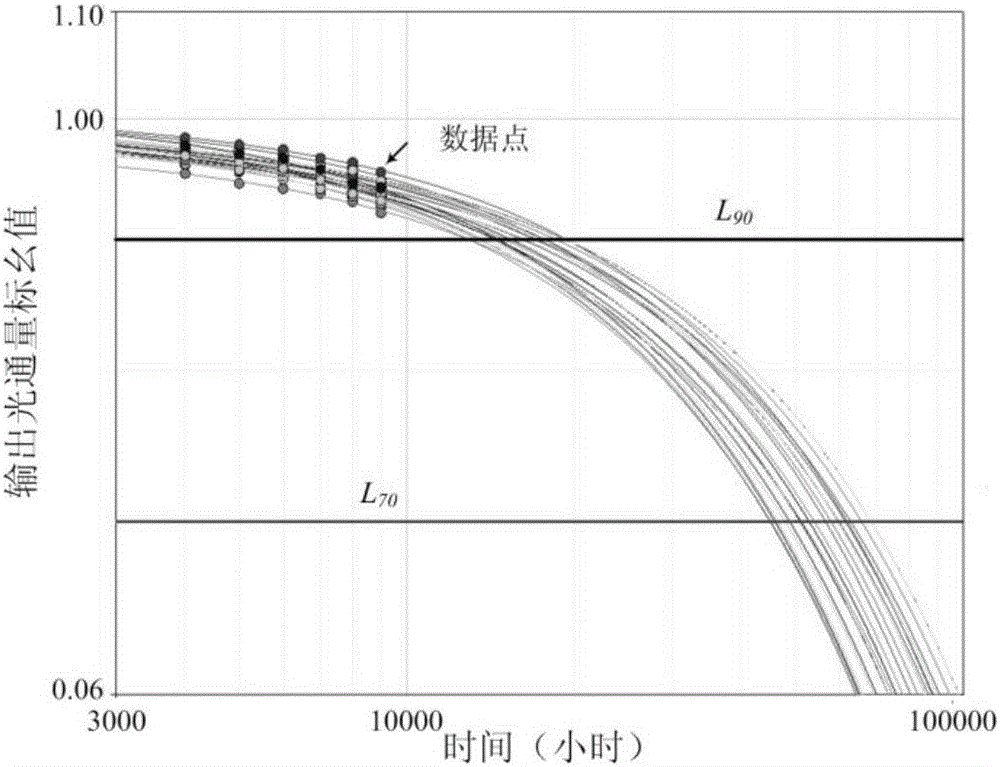

[0054] The experiment selects Luxeon K2 white light LED from Lumileds Company. Three sets of different driving current and junction temperature conditions were selected from its IES LM-80 report data (I F ,T J ) under the output luminous flux data, select L p Life standard, get three groups of different drive current I F and junction temperature T J L under condition p data such as figure 1 , figure 2 , image 3 shown. make L p The data obeyed the Weibull distribution, and the least square method was used for linear fitting to obtain three different Weibull curves. Different environmental stress (I F ,T J ) and L p The size of the shape parameter β obtained under the life standard should be the same. Depend on Figure 4 with Figure 5 Available in different L p B under standard X The activation energy E of the lifetime model a ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com