A dual-loop gasification combustion system, method and application based on circulating fluidized bed

A technology of circulating fluidized bed and combustion system, which is applied in gasification process, granular/powdered fuel gasification, and production of combustible gas. The problem of limited gas-solid separation efficiency of the separator, to achieve good particle circulation rate and combustion efficiency, to achieve efficient clean conversion and utilization, easy to operate and controllable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

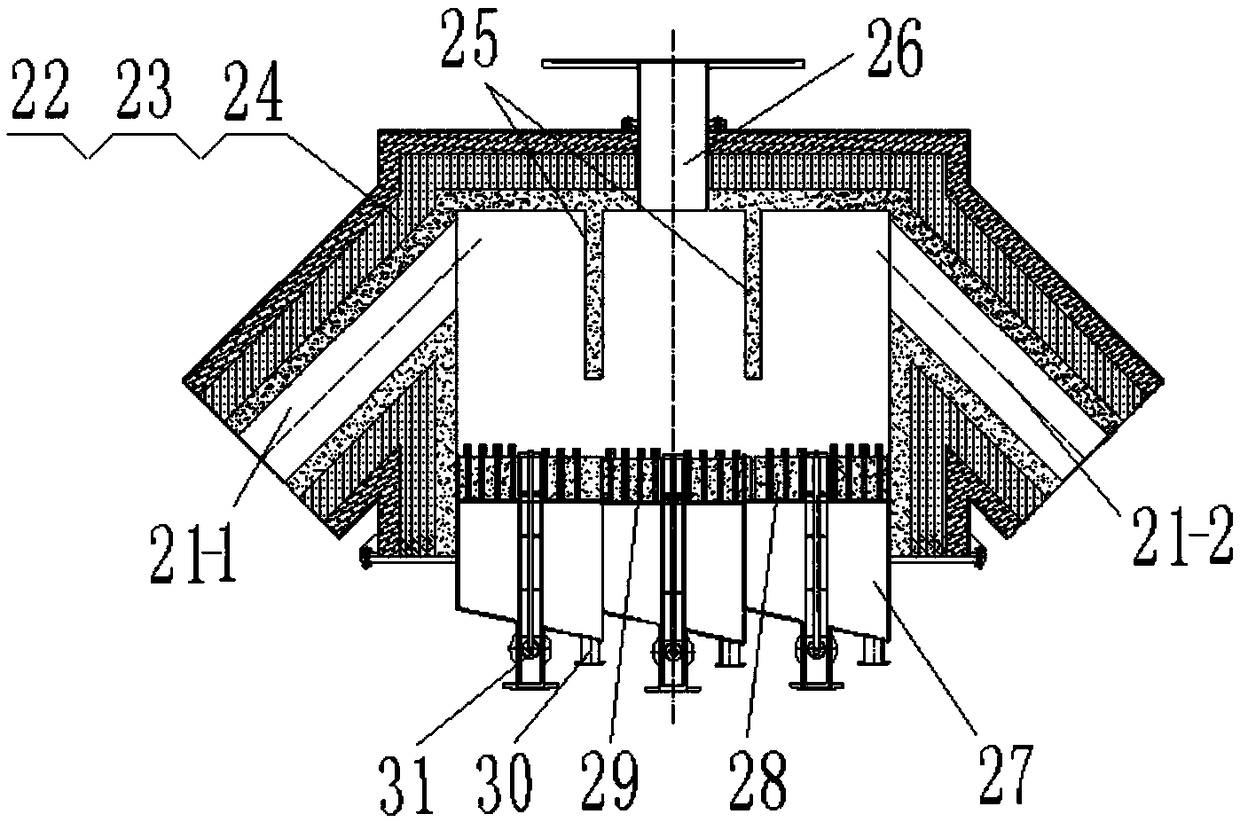

[0043] Such as figure 1As shown, the dual-loop gasification combustion system based on circulating fluidized bed of the present invention includes a gasification furnace 2, a primary cyclone separator 3, a heat exchange device 4, a secondary cyclone separator 5, a boiler 6, a fan 8, Chimney 9, ash bin 10, primary return valve 12, secondary return valve 11 and four delivery valves 13, the gas outlet of gasifier 2 is connected with the gas inlet of primary cyclone separator 3, the primary cyclone The gas outlet of the separator 3 is connected with the heat medium inlet of the heat exchanger 4, the heat medium outlet of the heat exchanger 4 is connected with the gas inlet of the secondary cyclone separator 5, and the gas outlet of the secondary cyclone separator 5 is connected with the boiler 6, The exhaust gas outlet of the boiler 6 communicates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com