Self-sealing protective structure for eliminating the gap between the anti-blast door and the ground under the action of shock waves

A protective structure, self-sealing technology, applied in sealing devices, special equipment for doors/windows, windows/doors, etc., can solve the problem of shock wave leakage, difficulty in adjusting the gap between the door and the ground, and affect the safety of people and equipment outside the door. and other problems to achieve the effect of reducing the difficulty of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

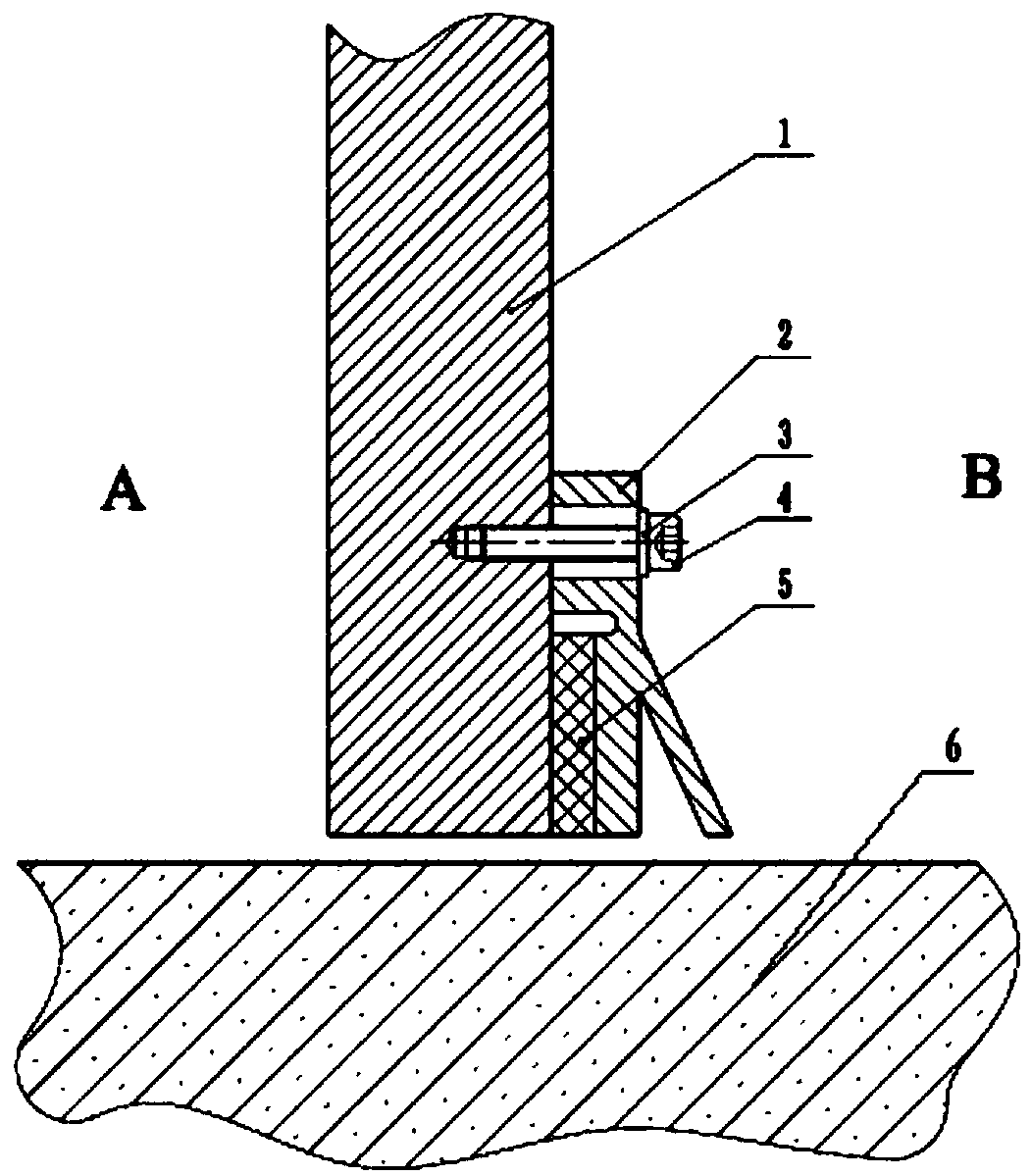

[0023] a kind of like figure 1 The shown self-sealing protection structure is used to eliminate the gap between the anti-blast door and the ground under the action of shock waves. The self-sealing protection structure is composed of a Y-shaped movable sealing strip 2 and an adjusting backing plate 5. The Y-shaped movable sealing strip is inverted Installed on the door panel 1, the bottom of the Y-shaped movable sealing strip is flush with the bottom of the door panel; the Y-shaped movable sealing strip is composed of an upper half of a cuboid and a lower half of an inverted V-shaped body, and the upper half of the cuboid is passed through a bolt 4. It is tightly connected with the door panel. The lower half of the inverted V-shaped body is composed of a vertically downward plate and an obliquely downward plate. The vertically downward plate is close to the door panel and has a gap with the door panel; the adjustment backing plate It is arranged in the gap between the lower hal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com