A weft-connecting rapier suitable for flat gold thread textiles and rapier looms

A technology of rapier looms and textiles, applied in the field of weft-joining swords, which can solve problems such as inability to meet yarn processing requirements, poor matching effect of concave-convex grooves, insufficient weft yarn clamping force, etc., and achieve safe and reliable use, simple and stable structure, The effect of short movement distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

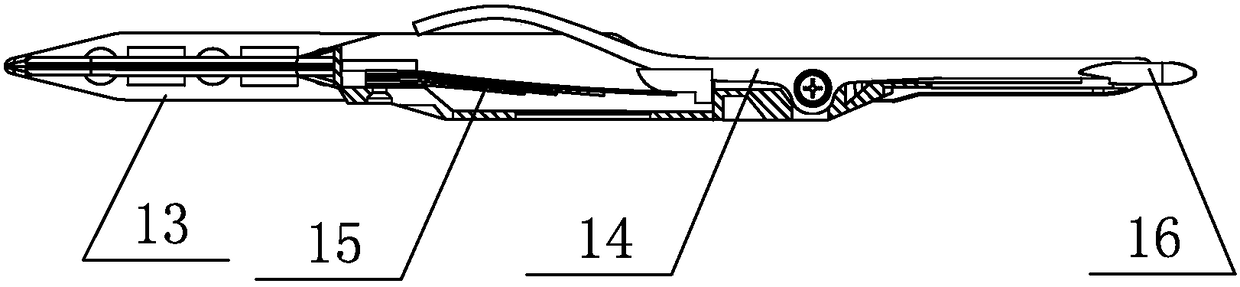

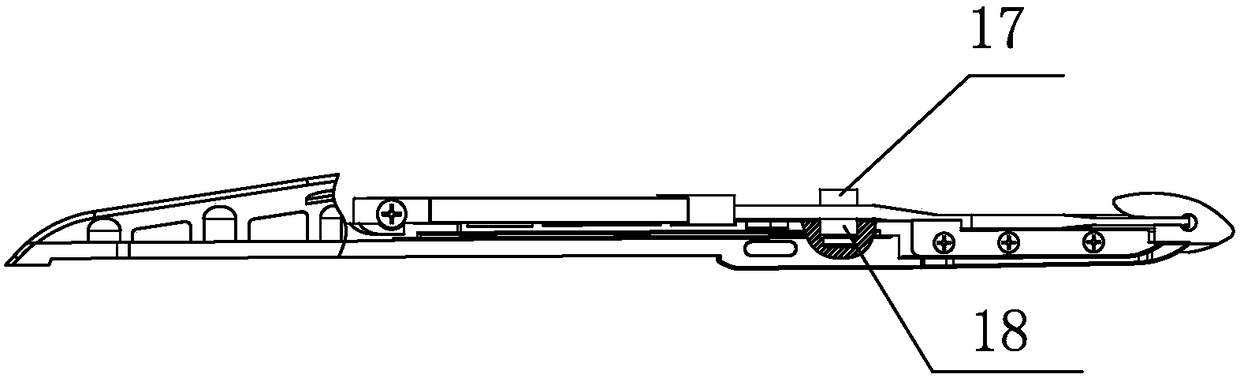

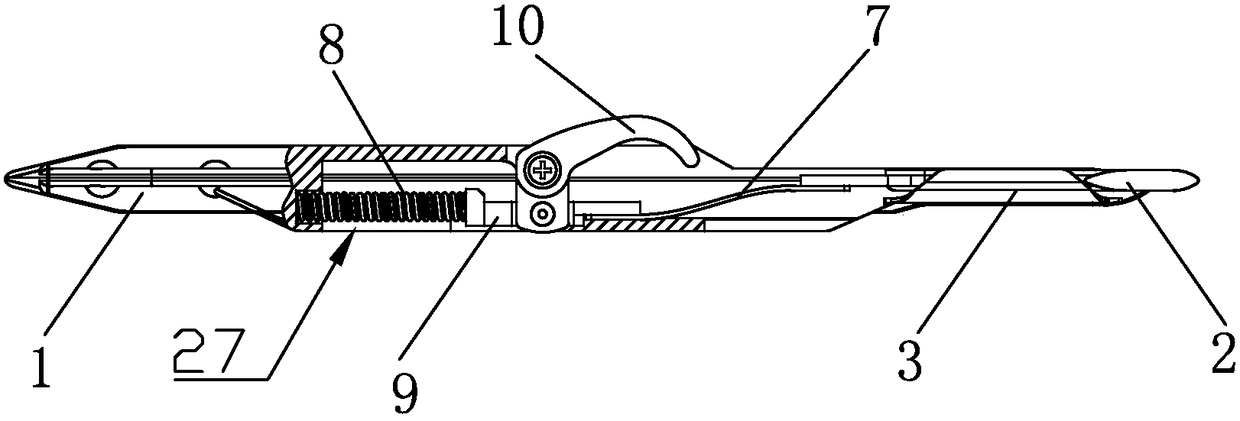

[0039] Such as Figure 1 to Figure 11 As shown, a weft-connecting rapier suitable for flat gold silk textiles and rapier looms includes a sword case 1, a hook head 2 and a motion actuator. The hook head 2 is fixed on the sword case 1 by screws, and the motion actuator Installed in the sword case 1, the hook head 2 is provided with a yarn end guide device, the hook head 2 is connected to the motion actuator, and the motion actuator includes the yarn clamping head 4, the pull bar 7, the linkage spring seat 9, the opening and closing device 10 and the compression Spring 8, the hook head 2 is connected to the clamping head 4, the yarn clamping head 4 is connected to the pull bar 7, the pull bar 7 is connected to the linkage spring seat 9, the middle part of the linkage spring seat 9 is provided with an opening and closing device 10, and the end of the linkage spring seat 9 A compression spring 8 is provided. The weft-joint rapier has fewer accessories, which makes the whole rapie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com