Method for recovering boron and magnesium from calcium magnesium dreg in boron-containing brine

A calcium-magnesium slag and boron-magnesium technology, which is applied in the field of boron-magnesium recovery from calcium-magnesium slag in boron-containing brine, can solve problems such as unsuitable industrial application and compositional differences of calcium-magnesium slag, and achieve high recovery value, cost saving, and simple reaction principle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

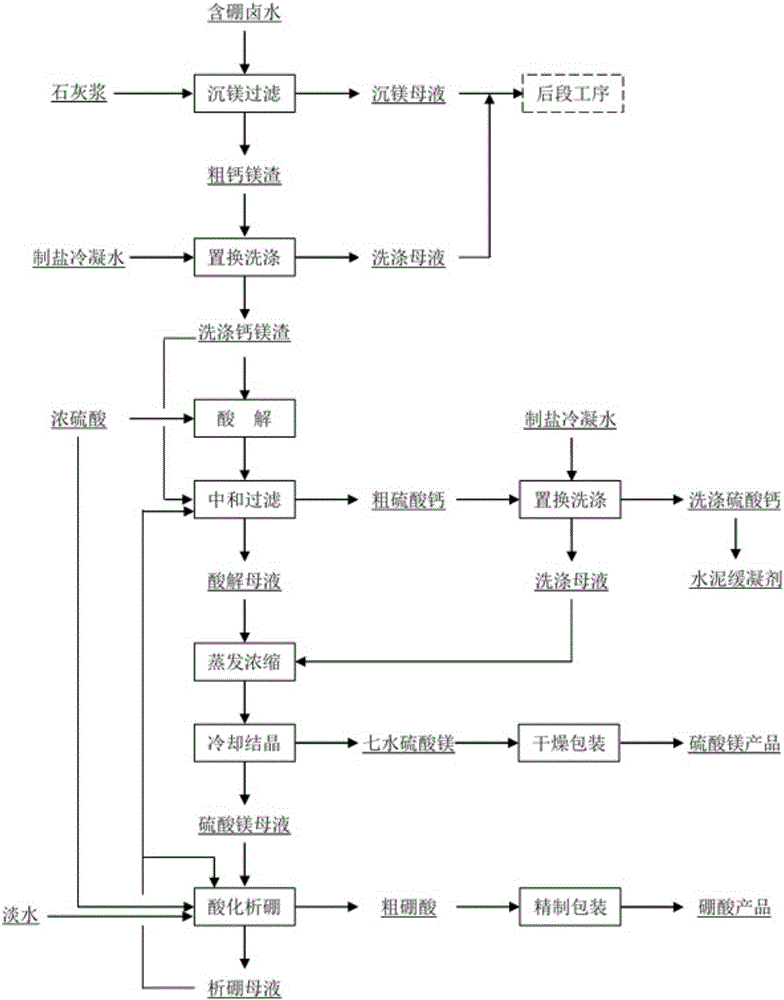

Method used

Image

Examples

Embodiment 1

[0029] Take 20L of brine, heat it to 50°C and keep it warm, add milk of lime with a mass concentration of 20% to the brine, adjust the pH of the solution to 10.4, add the milk of lime for 2 hours, and age for 2 hours after adding the milk of lime. After 15ml of flocculant was left to settle for 30 minutes, the upper layer was cleared away, and the lower layer was filtered and separated by a vertical plate and frame filter press to obtain coarse calcium and magnesium slag. The filter cake was washed with 2000ml of fresh water at 60°C for several times , to obtain calcium magnesium slag.

[0030] Add the obtained calcium-magnesium slag into 1+1 sulfuric acid under stirring conditions, and the addition time is 1 hour, so that the pH of the solution reaches 6.5, and then take an appropriate amount of calcium-magnesium slag slurry and add it to the acidified slurry, slowly adjusting to The pH of the solution is 7.5, the precipitate is filtered to obtain crude calcium sulfate, the f...

Embodiment 2

[0033] Take 25L of brine, heat it to 55°C and keep it warm, add milk of lime with a mass concentration of 25% to the brine, adjust the pH of the solution to 11, add the milk of lime for 1 hour, and age for 1.5 hours after adding the milk of lime. After 20ml of flocculant was left to settle for 60 minutes, the upper layer was cleared away, and the lower layer was filtered and separated by a vertical plate and frame filter press to obtain coarse calcium and magnesium slag. The filter cake was washed with 2500ml of 80°C fresh water for several times , to obtain calcium magnesium slag.

[0034] Add the obtained calcium-magnesium slag to 1+1 sulfuric acid under stirring conditions, and the addition time is 1.5 hours, so that the pH of the solution reaches 6.5, and then take excess calcium-magnesium slag and add it to the acidified slurry, and slowly adjust to the solution pH to 7.2, the precipitate is filtered to obtain crude calcium sulfate, the filtrate is evaporated and concentr...

Embodiment 3

[0037] Take 30L of brine, heat it to 60°C and keep it warm, add milk of lime with a mass concentration of 20% to the brine, adjust the pH of the solution to 12, add the milk of lime for 1 hour, and age for 2 hours after adding the milk of lime. After 25ml of flocculant was left to settle for 2 hours, the upper layer was cleared away, and the lower layer of slurry was filtered and separated by a vertical plate and frame filter press to obtain coarse calcium and magnesium slag. The filter cake was rinsed with 3000ml of fresh water at 60°C for several times. Wash to get calcium and magnesium slag.

[0038] Add the obtained calcium-magnesium slag to 1+1 sulfuric acid under stirring conditions, and the addition time is 1 hour to make the pH of the solution reach 6.5. 8. Filter the precipitate to obtain crude calcium sulfate, evaporate and concentrate the filtrate, when the mass concentration of magnesium ions in the filtrate reaches 120g / l, naturally cool the filtrate to normal tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com