Method and device for realizing dynamic balance, energy saving and self-weight requirement reduction of traction elevator

A dynamic balance and traction technology, applied in the field of elevators, can solve the problems of inability to recycle energy at the same time, short service life of supercapacitors, pollute the power grid, etc., and achieve the effects of reducing the demand for traction force, reducing positive pressure, and reducing operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

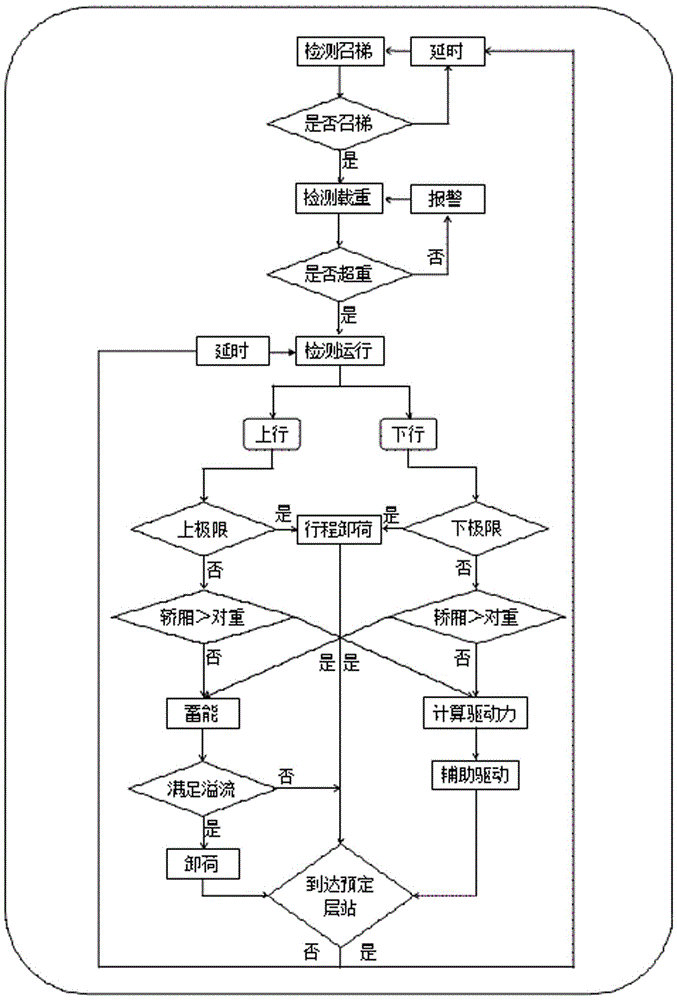

[0059] The present invention will be further described below in conjunction with the accompanying drawings.

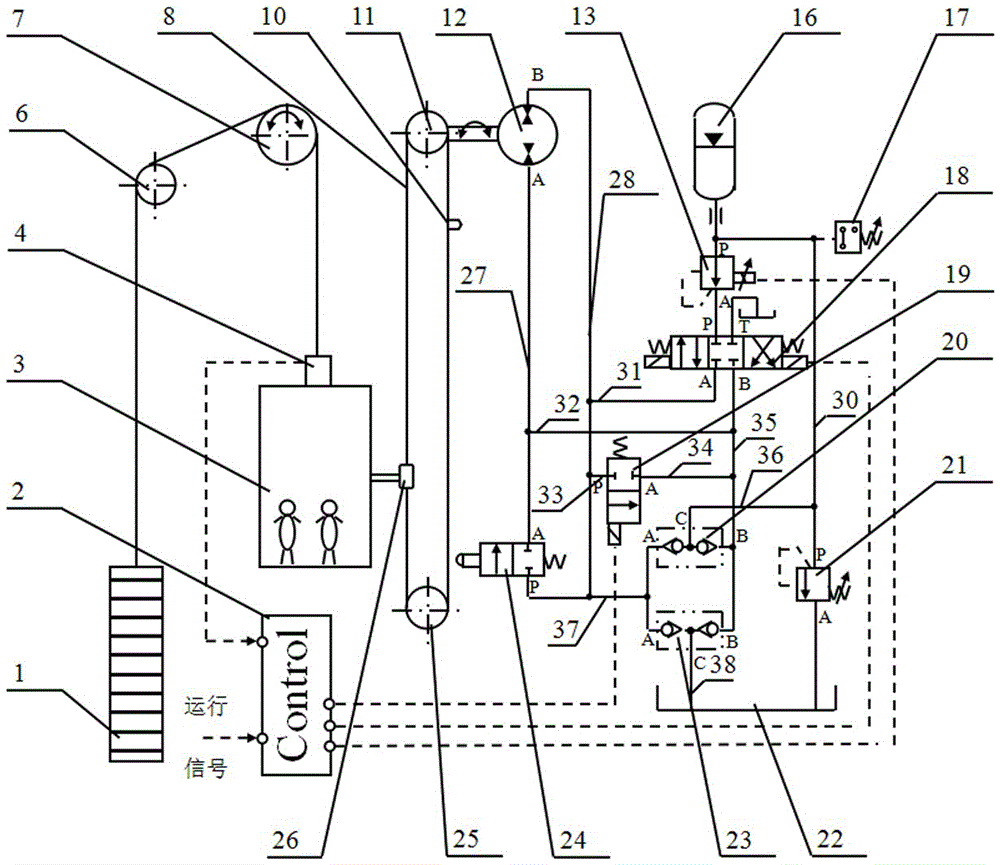

[0060] Such as figure 1 As shown, the device for traction elevator dynamic balance, energy saving and self-weight reduction requirements of the present invention includes an auxiliary traction device, a hydraulic energy storage device and an electrical control device; the auxiliary traction device includes a fixed joint 26, a chain 8, Upper sprocket 11, pump motor 12, lower sprocket 25 and retaining iron 10, chain 8 is contained on upper sprocket 11 and lower sprocket 25, upper sprocket 11 is connected with pump motor 12, lower sprocket 25 is provided with Tightening device; chain 8 is connected with car 3 by fixed joint 26, and stop iron 10 is contained on the chain 8.

[0061] The hydraulic energy storage device includes an electric proportional pressure reducing valve 13, an accumulator 16, a pressure relay 17, a three-position four-way electromagnetic directional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com