Forming structure provided with lateral-pushing sliding blocks

A forming structure and slider technology, applied in metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of unreachable precision, unstable size, weak rebound, etc., and achieve difficult to change, stable and reliable product size, Good molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. However, the scope of protection of the present invention is not limited to the following examples, that is, any simple equivalent changes and modifications made based on the patent scope of the present invention and the content of the description are still within the scope of the patent of the present invention.

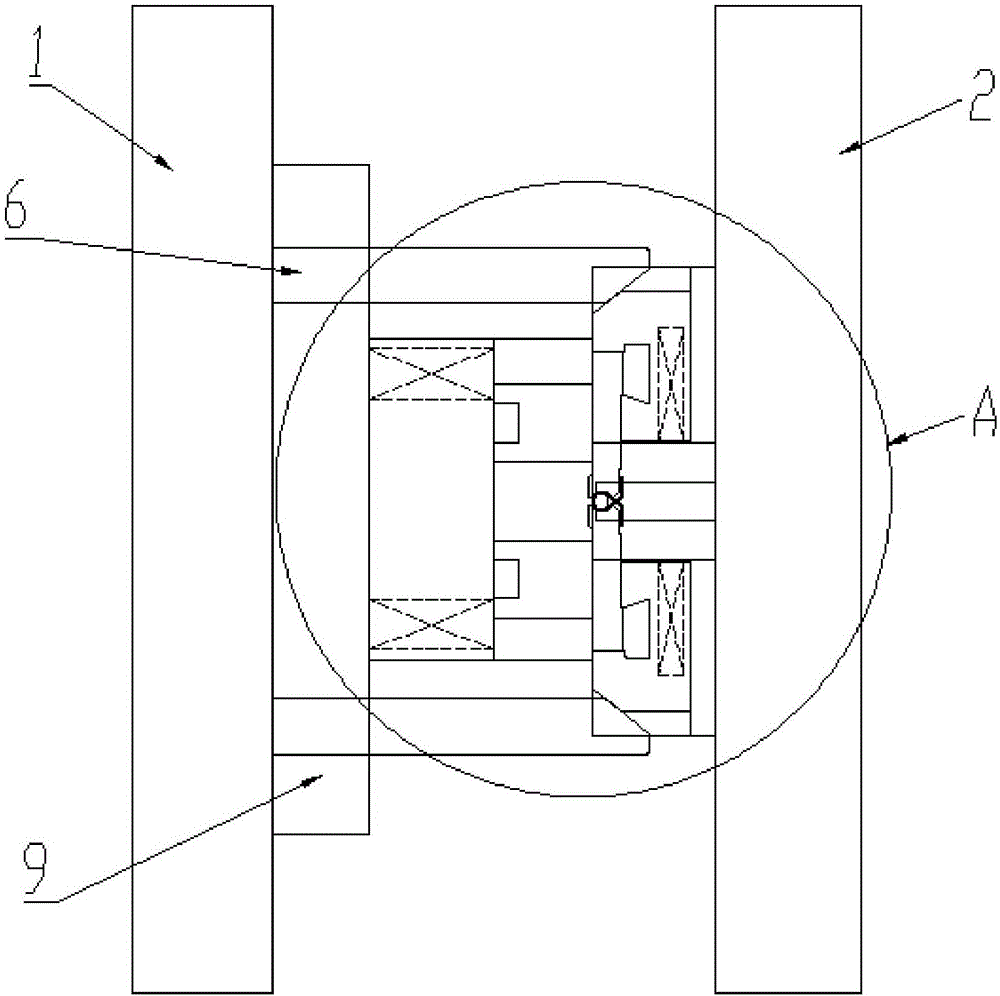

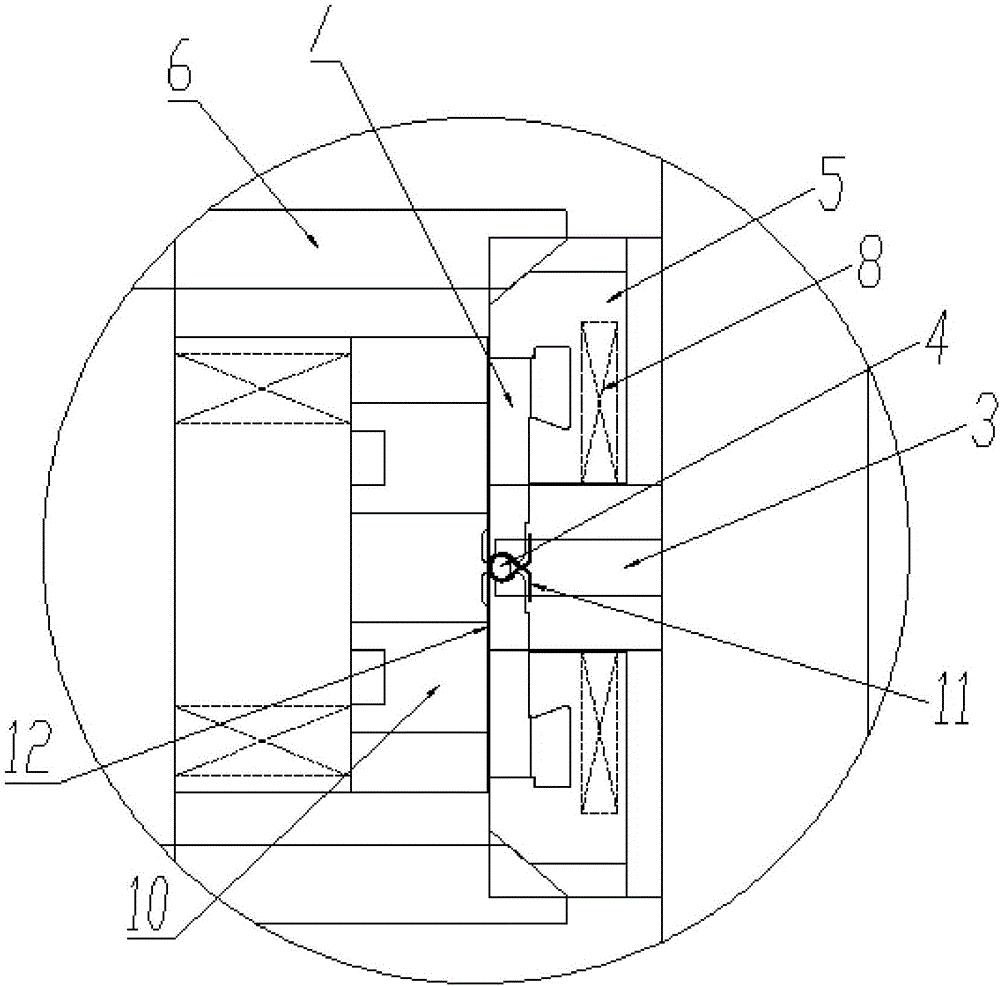

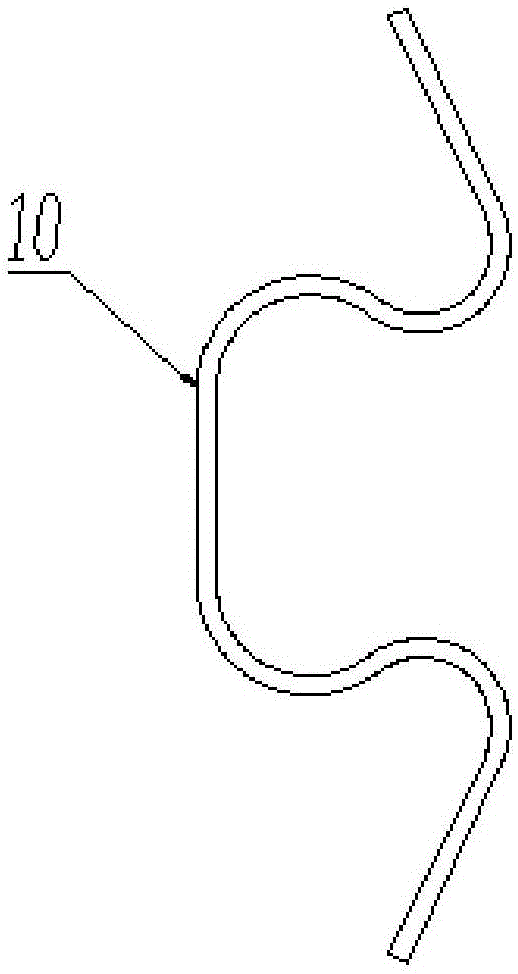

[0021] refer to Figure 1-4 , a side push slider molding structure, including an upper mold base 1 and a lower mold base 2 arranged in parallel, the length direction of the upper side of the lower mold base is the X direction, and the width direction is the Y direction, so as to be perpendicular to the lower mold base The direction of the upper side of the seat is in the Z direction, and the upper side of the lower mold base is fixed with a lower mold insert 3 for fixing the product, and the lower mold insert is fixed with a mandrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com