Method for predicting changes of rolling pressure with change of rolling speed in cold rolling process

A technology of rolling speed and rolling pressure, which is applied in the field of forecasting of rolling speed changes, to ensure surface quality and shape accuracy, avoid fluctuations out of tolerance, and improve brand competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

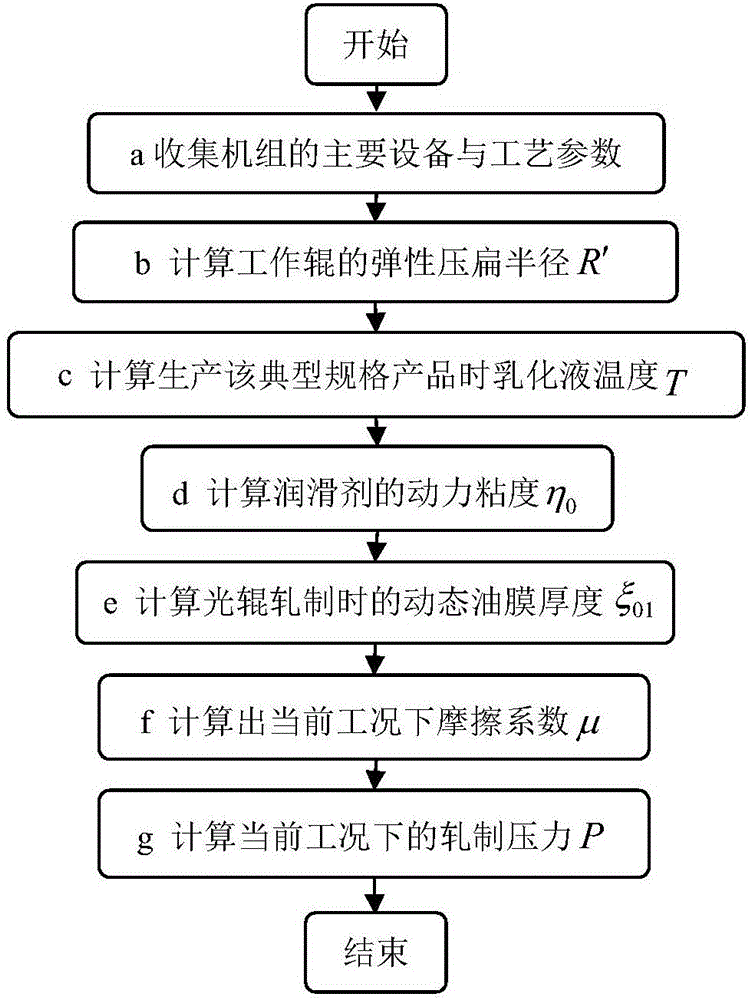

[0027] A method suitable for forecasting the change of rolling pressure with rolling speed in the cold rolling process, the calculation steps are as follows figure 1 Shown:

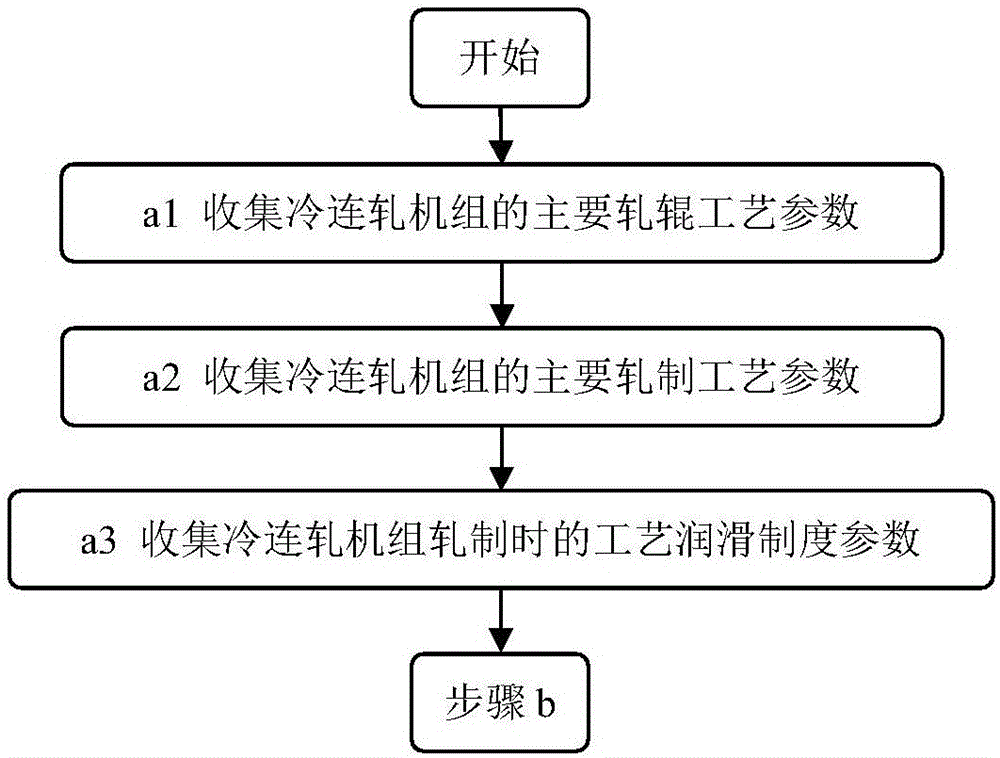

[0028] First, in step a, the main equipment and process parameters of the cold tandem mill are collected, such as figure 2As shown, it mainly includes the following steps:

[0029] In step a1, the process parameters of the rolls are collected, the work roll radius R=203.43mm, the surface roughness Ra r = 0.53μm, Young's modulus E of the work roll = 206GPa, Poisson's ratio ν of the work roll = 0.3;

[0030] Subsequently, in step a2, the rolling process parameters are collected, the average deformation resistance K of the strip m =502MPa, strip width B=812mm, incoming material thickness h 0 =2.01mm, reduction rate ε i ={44.3,44.2,38.1,32.5,19.3}%, rolling speed data V j ={149.6,292.3,328.3,449.2,585.5,601.2,796.7,833.5,939.2,1087.1,1143.5}m / min, tension value σ i = {60.2, 129.8, 146.4, 156.4, 164.6,...

Embodiment 2

[0047] First, in step a, the main equipment and process parameters of the cold tandem rolling mill are collected, which mainly includes the following steps:

[0048] In step a1, the roll process parameters are collected, the work roll radius R=204.29mm, the surface roughness Ra r = 0.52μm, Young's modulus E of the work roll = 206GPa, Poisson's ratio ν of the work roll = 0.3;

[0049] Subsequently, in step a2, the main rolling process parameters are collected, the average deformation resistance K of the strip m =502MPa, strip width B=1020mm, incoming material thickness h 0 =2.23mm, reduction rate ε i ={44.5,44.4,38.3,32.8,20.3}%, rolling speed data V j ={146.2,286.7,322.3,444.3,583.2,600.2,792.8,832.2,932.6,1086.2,1142.7}m / min, tension value σ i = {57.8, 129.0, 145.5, 155.5, 163.8, 62.8} MPa;

[0050] Subsequently, in step a3, collect process lubrication system parameters, emulsion flow rate w i ={1023,1362,1140,1067,1266}L / min, emulsion concentration C=4.2%, initial emul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com