Formaldehyde film degraded by photocatalytic mechanism

A technology of photocatalysis and photocatalytic materials, which is applied in the field of photocatalytic degradation of formaldehyde film, can solve the problems of short service life and low product efficiency, and achieve the effects of short service life, increased product life and improved catalytic degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

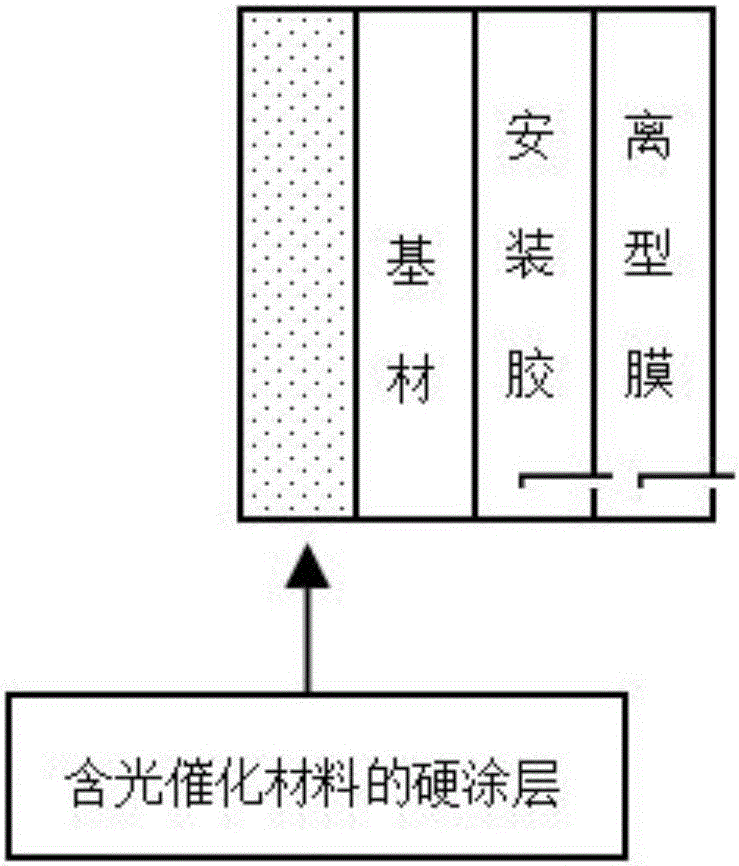

[0031] Embodiment 1: The structure of photocatalytic degradation formaldehyde film

[0032] The product structure of the present invention is as figure 1 shown.

[0033] The photocatalytic degradation formaldehyde film of the present invention mainly comprises nanometer TiO 2 Hard coating layer, substrate layer, installation adhesive layer, release film layer. The dispersed nano-TiO 2 The hard coating layer is located on the outermost layer of the photocatalytic degradation formaldehyde film, with a thickness of 1-5 μm; the thickness of the installation adhesive layer is 5-15 μm. The installation adhesive layer is mainly used for laminating installation, and the release film is mainly used to protect the installation adhesive.

Embodiment 2

[0034] Embodiment 2: the preparation of photocatalytic degradation formaldehyde film

[0035] Prepare the photocatalytic degradation formaldehyde film according to the following method:

[0036] (1) Configure a certain concentration of installation glue;

[0037] (2) Evenly coat the mounting glue on the surface of one side of the substrate; the thickness of the mounting glue is about 10 μm;

[0038] (3) A certain amount of photocatalytic material TiO 2 Add to base hard coat components, specifically:

[0039] In parts by weight, first add 15 parts of solvent ethyl acetate in the glue barrel; then add 0.8 parts of photocatalytic material nano-TiO 2 Add it into a bucket filled with solvent and stir for 1.5h; then add 10 parts of acrylic resin, and ultrasonically disperse for 0.5h; then add 0.1 part of adhesion promoter, 0.1 part of light stabilizer, 0.1 part of photoinitiator, etc. and fully stir for 1.5h , to obtain a uniformly dispersed hardening solution coating. Nano-TiO...

Embodiment 3

[0052] Embodiment 3: the preparation of photocatalytic degradation formaldehyde film

[0053] Prepare the photocatalytic degradation formaldehyde film according to the following method:

[0054] (1) Configure a certain concentration of installation glue;

[0055] (2) Evenly coat the mounting glue on the surface of one side of the substrate; the thickness of the mounting glue is about 5 μm;

[0056] (3) A certain amount of photocatalytic material TiO 2 The dispersion is added to the base hardcoat composition, specifically:

[0057] In parts by weight, first add 13 parts of solvent ethyl acetate in the glue barrel; then add 0.7 parts of photocatalytic material nano-TiO 2 Add it into a bucket filled with solvent and stir for 1.5h; then add 8 parts of acrylic resin, and ultrasonically disperse for 0.5h; then add 0.08 parts of adhesion promoter, 0.08 parts of light stabilizer, 0.08 parts of photoinitiator, etc. and fully stir for 1.5 hours , to obtain a uniformly dispersed hard...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com