Bioreactor

A bioreactor and reactor technology, applied in biological sludge treatment, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problem that organic waste cannot be further recycled and used, and reduce the amount of sludge treatment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

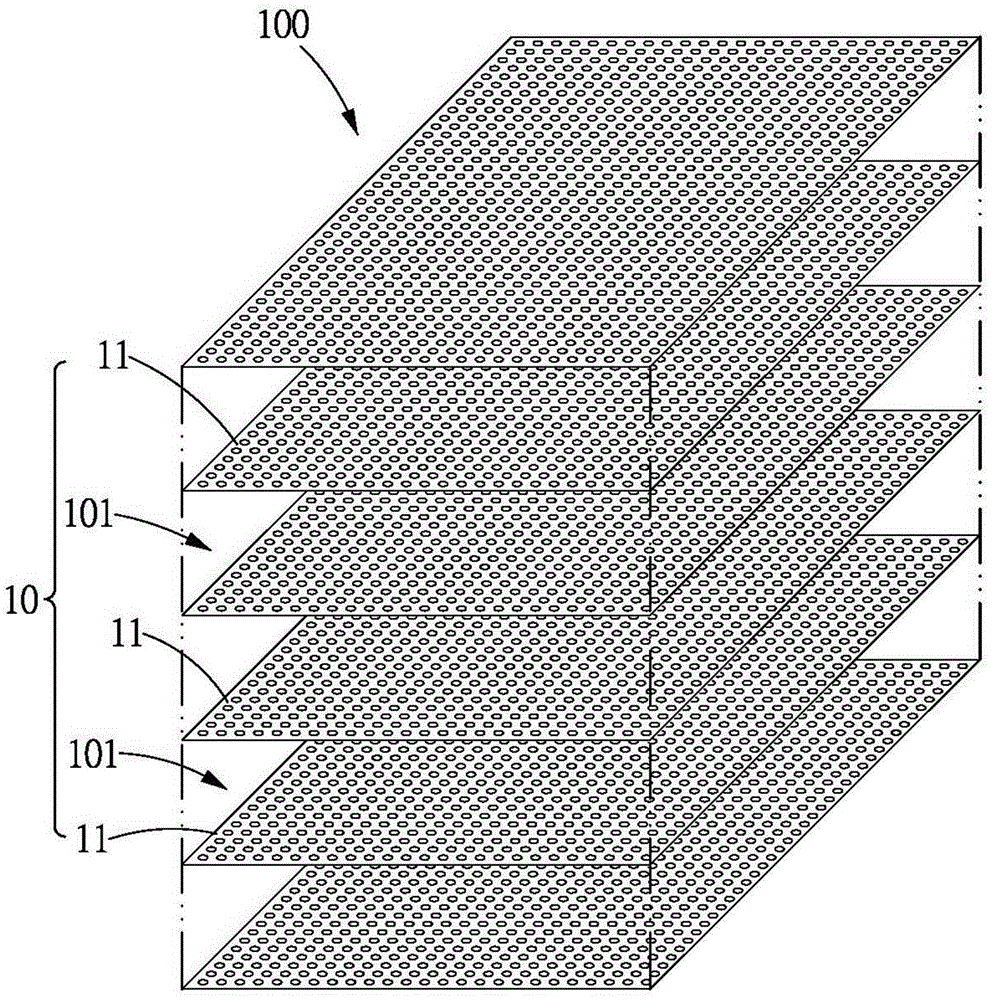

Embodiment 1

[0063] Example 1: with figure 2 Exhaust gas treatment of a casing production plant in the suburbs of Beijing with the same equipment. The horizontal multilayer reactor in the adsorption tower is provided with five layers of horizontal spaces, which are respectively inserted into organic carriers and inorganic carriers; the vertical multilayer reactor in the reactor of the circulation operation section has four layers of vertical spaces, respectively inserted into organic Carriers and Inorganic Carriers. After the bioreactor is placed in the adsorption tower and the reactor, a considerable proportion of comprehensive microbial preparations are injected in a regular and quantitative manner, and compounded with the carrier to form a microbial deodorant. Then, as shown in Table 1 below, at 60M per minute 3The flow rate of the organic waste gas is passed into the organic waste gas, and the main odor source of the organic waste gas includes about 200ppm of NH 3 and about 120ppm ...

Embodiment 2

[0065] Example 2: with image 3 The kitchen waste water treatment of Fu Hua Hotel in Taipei City with the same equipment. The second reaction tank of the grease trap is provided with two single-layer bioreactors at the same level, and the mixed organic carrier and inorganic carrier are respectively placed; a horizontal multi-layer reaction device is arranged in the second drainage tank of the grease trap There are three levels of horizontal space, which are respectively placed with organic carriers and inorganic carriers. After the bioreactor is placed in the grease trap, a considerable proportion of comprehensive microbial preparations are injected in a regular and quantitative manner, and compounded with the carrier to form a microbial deodorant. Then, as shown in Table 2 below, the daily inflow from the kitchen is about 40M 3 The amount of oily wastewater is monitored, and the oil content in the water (FOG, Fats, Oils and Greases) is monitored, and the discharge standard ...

Embodiment 3

[0067] Example 3: with Figure 4 High-concentration organic sludge water treatment of Yilan Fuchang pig farm with the same equipment. The waste water processor is provided with two horizontal multi-layer reactors each having four layers of horizontal space, which are respectively inserted into organic carriers and inorganic carriers; the waste water processor is provided with two vertical multi-layer reactors each having three layers of vertical spaces, respectively organic and inorganic carriers. After the bioreactor is placed in the waste water processor, a considerable proportion of comprehensive microbial preparations are injected in a regular and quantitative manner, and compounded with the carrier to form a microbial deodorant. Next, as shown in Table 3 below, the daily inflow is about 1.5-2.0M 3 High-concentration organic sludge water (the raw liquid after solid-liquid separation of pig manure and urine), and monitor the mixed liquid suspended solids (MLSS, Mixed Liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com