Dried orange peel and red bean cakes and manufacturing technology thereof

A manufacturing process, the technology of red bean cake, applied in the field of orange peel red bean cake and its manufacturing process, can solve the problems of poor taste, easy deformation, beany flavor and bitter taste, etc., and achieve unique taste, increase appetite, and no bean flavor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

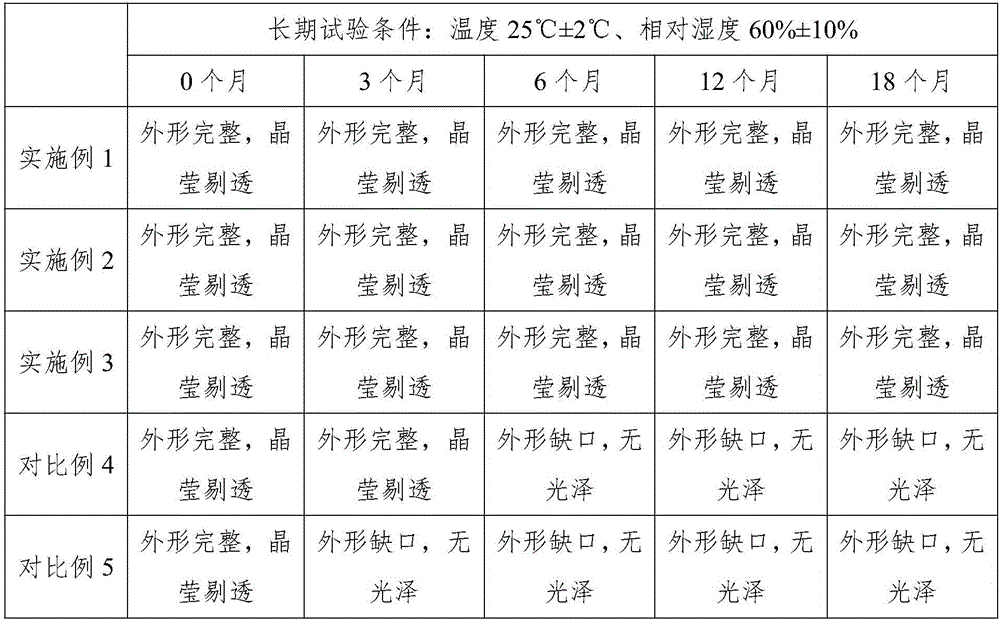

Examples

Embodiment 1

[0033] Embodiment 1, a kind of tangerine peel red bean cake

[0034] Described tangerine peel red bean cake is made up of following preparation raw material and parts by weight thereof:

[0035] 12 parts of red beans, 6 parts of tangerine peel, 4 parts of hawthorn, 4 parts of sweet-scented osmanthus, 8 parts of sorbitol and 64 parts of agar.

[0036] Preparation:

[0037] S1 Add the red beans to the sodium dihydrogen phosphate solution with a pH value of 3.6, soak for 6 hours at a temperature of 45°C, the amount of the sodium dihydrogen phosphate solution added is 3 times the weight of the red beans, wash, drain, Add water and heat for 40 minutes using a microwave with a power of 280W to get cooked red beans;

[0038] S2 Wash the tangerine peel and hawthorn, place the dried tangerine peel and hawthorn at a temperature of 68°C for 10 hours, pulverize the dried tangerine peel and hawthorn, pass through 80 meshes, and then perform ultrafine grinding. The average particle size o...

Embodiment 2

[0042] Embodiment 2, a kind of tangerine peel red bean cake

[0043] Described tangerine peel red bean cake is made up of following preparation raw material and parts by weight thereof:

[0044] 15 parts of red beans, 10 parts of tangerine peel, 5 parts of hawthorn, 5 parts of sweet-scented osmanthus, 14 parts of sorbitol and 74 parts of agar.

[0045] Preparation:

[0046] S1 Add the red beans to the sodium dihydrogen phosphate solution with a pH value of 4.0, soak for 7 hours at a temperature of 50° C., the added amount of the sodium dihydrogen phosphate solution is 4 times the weight of the red beans, wash, drain, Add water and heat for 50 minutes using a microwave with a power of 300W to get cooked red beans;

[0047] S2 Wash the tangerine peel and hawthorn, place the dried tangerine peel and hawthorn at a temperature of 72°C for 11 hours, pulverize the dried tangerine peel and hawthorn, pass through 80 meshes, and then perform ultrafine grinding. The average particle si...

Embodiment 3

[0051] Embodiment 3, a kind of tangerine peel red bean cake

[0052] Described tangerine peel red bean cake is made up of following preparation raw material and parts by weight thereof:

[0053] 20 parts of red beans, 14 parts of tangerine peel, 6 parts of hawthorn, 6 parts of sweet-scented osmanthus, 16 parts of sorbitol and 80 parts of agar.

[0054] Preparation:

[0055] S1 Add the red beans to the sodium dihydrogen phosphate solution with a pH value of 4.4, soak for 8 hours at a temperature of 55° C., the added amount of the sodium dihydrogen phosphate solution is 5 times the weight of the red beans, wash, drain, Add water and heat for 60 minutes using a microwave with a power of 320W to get cooked red beans;

[0056] S2 Wash the tangerine peel and hawthorn, place the dried tangerine peel and hawthorn at a temperature of 80°C for 12 hours, pulverize the dried tangerine peel and hawthorn, pass through 100 meshes, and then perform ultrafine pulverization. The average parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com