Processing method of fresh extracted apricot kernel juice

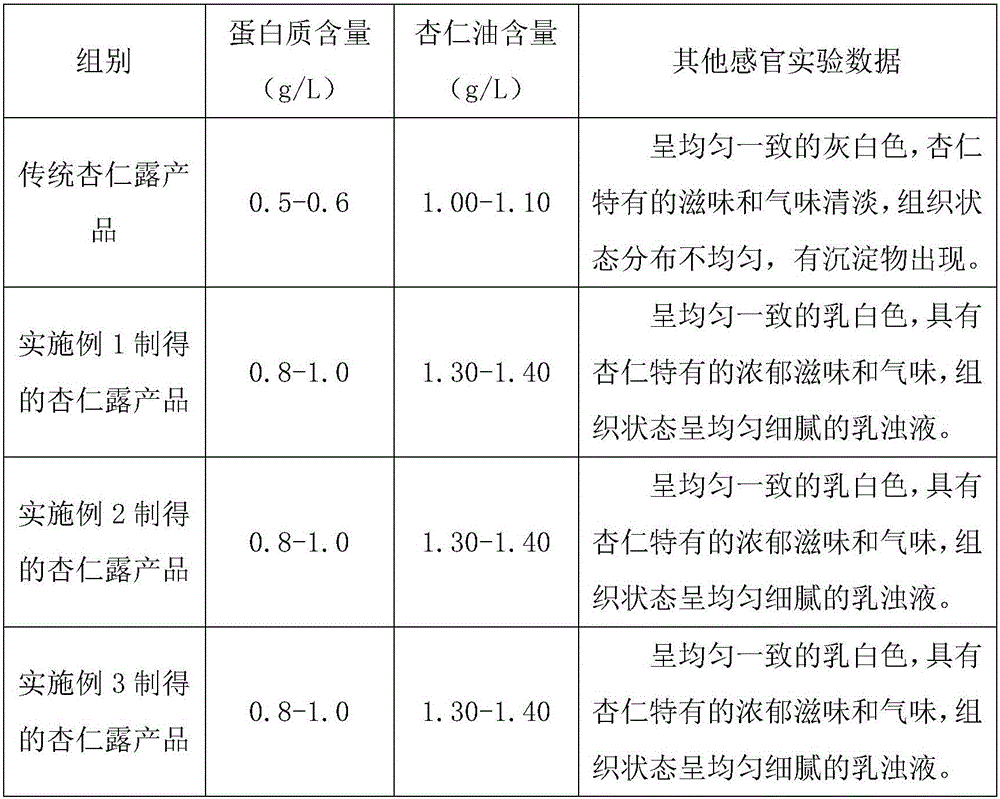

A processing method and technology for almonds, which are applied in the field of freshly squeezed almond dew processing, can solve the problems of dark, non-rich product, increase product turbidity, etc., and achieve the effects of strong aroma, high protein content, and improved visual effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A processing method for freshly squeezed almond milk, comprising: (1) material selection, (2) peeling, (3) debittering, (4) coarse grinding, (5) fine grinding, (6) centrifugal separation, (7) blending , (8) homogeneous, (9) sterilized filling; wherein,

[0026] (1) Material selection: screen apricot kernels, remove impurities, and remove the shell of apricot kernels with a pitting machine to obtain almonds, and carry out secondary screening on almonds to keep raw almonds that are free from mildew, insects, oxidation, and deterioration;

[0027] (2) Peeling: After the material selection is completed, put the raw almonds into hot water at 85°C for 15 minutes, then cool and clean the raw almonds with room temperature water, and finally perform mechanical peeling on the raw almonds;

[0028] (3) Debittering: After the peeling is completed, soak the peeled raw almonds in softened water at 25°C, the conductivity of the softened water is below 15us / cm, and the volume ratio of ...

Embodiment 2

[0036] A processing method for freshly squeezed almond milk, comprising: (1) material selection, (2) peeling, (3) debittering, (4) coarse grinding, (5) fine grinding, (6) centrifugal separation, (7) blending , (8) homogeneous, (9) sterilized filling; wherein,

[0037] (1) Material selection: screen apricot kernels, remove impurities, and remove the shell of apricot kernels with a pitting machine to obtain almonds, and carry out secondary screening on almonds to keep raw almonds that are free from mildew, insects, oxidation, and deterioration;

[0038](2) Peeling: After the material selection is completed, put the raw almonds into hot water at 85°C for 15 minutes, then cool and clean the raw almonds with room temperature water, and finally perform mechanical peeling on the raw almonds;

[0039] (3) Debittering: After the peeling is completed, soak the peeled raw almonds in softened water at 25°C, the conductivity of the softened water is below 15us / cm, and the volume ratio of r...

Embodiment 3

[0047] A processing method for freshly squeezed almond milk, comprising: (1) material selection, (2) peeling, (3) debittering, (4) coarse grinding, (5) fine grinding, (6) centrifugal separation, (7) blending , (8) homogeneous, (9) sterilized filling; wherein,

[0048] (1) Material selection: screen apricot kernels, remove impurities, and remove the shell of apricot kernels with a pitting machine to obtain almonds, and carry out secondary screening on almonds to keep raw almonds that are free from mildew, insects, oxidation, and deterioration;

[0049] (2) Peeling: After the material selection is completed, put the raw almonds into hot water at 85°C for 15 minutes, then cool and clean the raw almonds with room temperature water, and finally perform mechanical peeling on the raw almonds;

[0050] (3) Debittering: After the peeling is completed, soak the peeled raw almonds in softened water at 25°C, the conductivity of the softened water is below 15us / cm, and the volume ratio of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com