Lithium ion battery stepped formation and consistency screening method

A lithium-ion battery and screening method technology, which is applied in the field of step-by-step formation and consistency screening of lithium-ion batteries, can solve the problems of long battery consistency screening cycle, unstable SEI film formation, etc., to improve the consistency screening effect and reduce The effect of shortening the charging and discharging process and shortening the process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Taking the cylindrical 18650-2.2Ah-3.6V battery as an example, the positive electrode material is nickel cobalt lithium manganese oxide, and the negative electrode material is graphite. Its step-by-step formation and consistency screening process is as follows:

[0029] The first step is pre-charging. After the battery is filled with liquid and sealed, it is left for 5 hours, and it is charged with a current of 0.05C for 1 hour.

[0030] The second step is to store at high temperature, first at 35°C for 36h, then at 45°C for 24h.

[0031] The third step is secondary charging, using 0.2C current to charge to 50% of the design capacity.

[0032] The fourth step is high temperature storage, the storage temperature is 40~45°C, and the storage time is 48h.

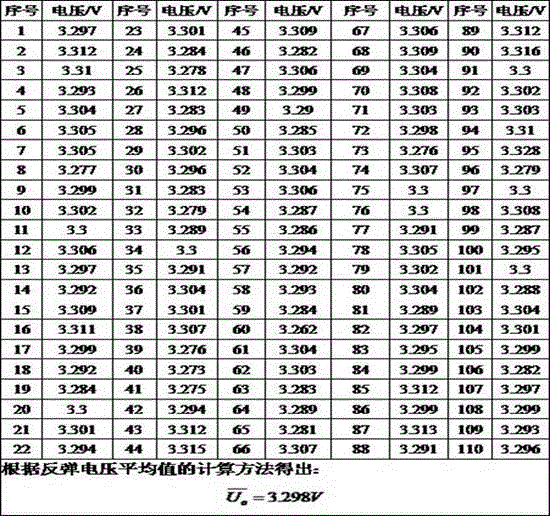

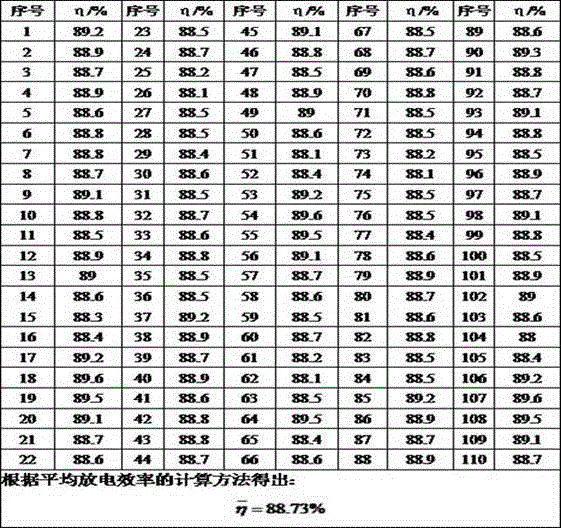

[0033] The fifth step is voltage internal resistance screening, and the battery is screened for voltage internal resistance. According to the characteristics of the battery voltage of the model =7mV, k=0.12 Calculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com