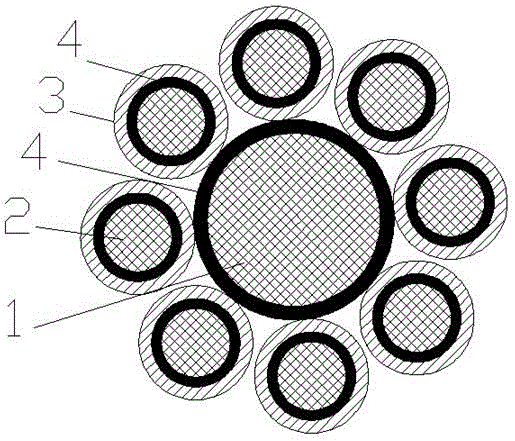

Compound rope with eight steel cores

A composite rope and eight-strand technology, applied in textile cables, textiles and papermaking, etc., can solve the problems of non-wear resistance, inconvenient operation, heavy specific weight, etc., and achieve the effects of high insurance factor, long service life and large breaking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0015] Such as figure 1 As shown, an eight-strand steel-core composite cable in this embodiment includes a central strand 1 and eight peripheral strands 2 surrounding the central strand 1. The central strand 1 is a steel core formed by twisting multiple stainless steel wires. The rigidity of the rope can be improved so that it is not easy to be elongated. The outer strands 2 are twisted from a plurality of chemical fiber ropes, and the eight strands of the outer strands 2 are woven and covered on the surface of the central strand 1 , can replace the steel wire rope, reduce the weight of the rope, increase the softness of the rope, the outer layer of the eight-fold d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com