Novel modified polypropylene plastic and preparation method thereof

A technology of polypropylene plastic and polypropylene, which is applied in the field of new modified polypropylene plastic and its preparation, can solve the problems of complex mechanism, unpredictability and inference, and achieve improved antistatic performance, improved flame retardant effect, and good process flow Effects on Sexuality and Mechanical Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

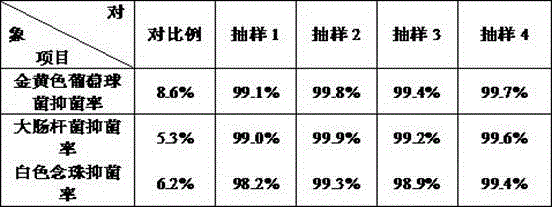

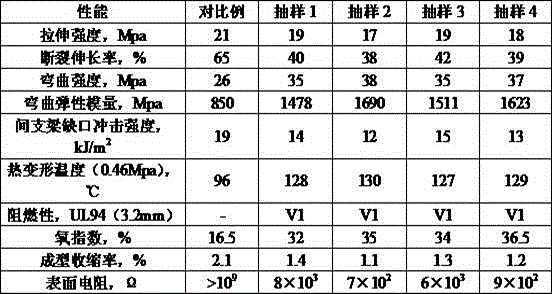

Embodiment 1

[0041] Embodiment 1 composite antibacterial agent preparation

[0042] The composite antibacterial agent is prepared by 10 parts by weight of chitosan, 1 part of dodecyltriphenylphosphonium chloride, 3 parts of bacterial cellulose, and 1 part of calcium chloride; specifically, the following steps Preparation: Bacterial cellulose is subjected to plasma treatment in an air atmosphere, the plasma voltage is 140V, the vacuum degree is 150Pa, the treatment time is 1-2min at room temperature, then dissolved in isopropanol solution, and quaternary phosphonium salt is added solution, stirred, cooled, washed and dried, then added calcium chloride and chitosan, uniformly dispersed and stirred for 30 minutes to obtain a composite antibacterial agent.

Embodiment 2

[0043] Embodiment 2 composite antibacterial agent preparation

[0044] Described composite antimicrobial agent is prepared by 12 parts of chitosan, 3 parts of tetradecyltriphenylphosphonium chloride, 10 parts of bacterial cellulose, and 1.2 parts of calcium chloride by weight parts; specifically by the following steps Preparation: Bacterial cellulose is subjected to plasma treatment in an air atmosphere, the plasma voltage is 140V, the vacuum degree is 150Pa, the treatment time is 1-2min at room temperature, then dissolved in isopropanol solution, and quaternary phosphonium salt is added solution, stirred, cooled, washed and dried, then added calcium chloride and chitosan, uniformly dispersed and stirred for 30 minutes to obtain a composite antibacterial agent.

Embodiment 3

[0045] Embodiment 3 composite antibacterial agent preparation

[0046] The composite antibacterial agent is prepared by 15 parts by weight of chitosan, 5 parts of cetyltriphenylphosphonium chloride, 15 parts of bacterial cellulose, and 1.5 parts of calcium chloride; specifically by the following steps Preparation: Bacterial cellulose is subjected to plasma treatment in an air atmosphere, the plasma voltage is 140V, the vacuum degree is 150Pa, the treatment time is 1-2min at room temperature, then dissolved in isopropanol solution, and quaternary phosphonium salt is added solution, stirred, cooled, washed and dried, then added calcium chloride and chitosan, uniformly dispersed and stirred for 30 minutes to obtain a composite antibacterial agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com