Craft glass forming die

A glass forming and mold technology, applied in glass forming, manufacturing tools, glass rolling, etc., can solve problems such as waste of raw materials and cumbersome processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

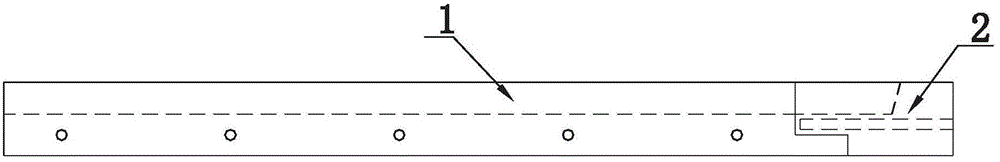

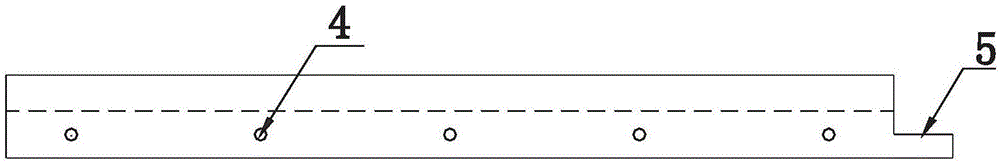

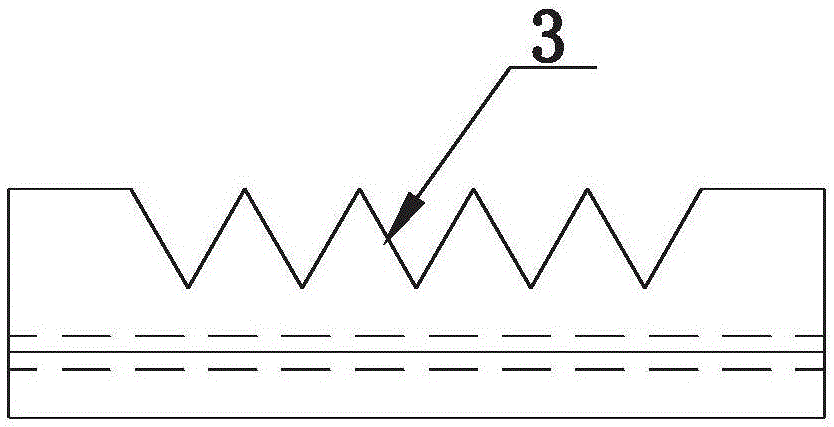

[0019] Such as Figure 1~Figure 7 As shown, a process glass forming mold includes a bottom mold 1 and a rear plug 2. The upper part of the bottom mold 1 is provided with a plurality of forming grooves 3 whose cross-sections are equilateral triangles, and the plurality of forming grooves 3 form a forming surface. , The bottom mold 1 is provided with a plurality of first cooling holes 4 , and one side of the bottom mold 1 is provided with a first protruding head 5 . The rear plug 2 is provided with diversion grooves 6 , the rear plug 2 is provided with a plurality of second cooling holes 7 , and one side of the rear plug 2 is provided with a second protruding head 8 . The bottom mold 1 and the rear plug 2 are tightly engaged and fixed by the first protruding head 5 and the second protruding head 8 in a stepped manner.

[0020] The plurality of molding grooves 3 are arranged side by side on the surface of the bottom mold 1 to form a molding surface.

[0021] The plurality of fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com