Apparatus and process for treating ammonia nitrogen wastewater and recycling ammonia

An ammonia nitrogen waste water and recycling technology, applied in heating water/sewage treatment, water/sludge/sewage treatment, water pollutants, etc. It can solve multiple automatic control instruments and automatic valves, no solution is proposed, and there are many sets of equipment. and other problems, to achieve the effect of less public works, less equipment sets, and less total investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

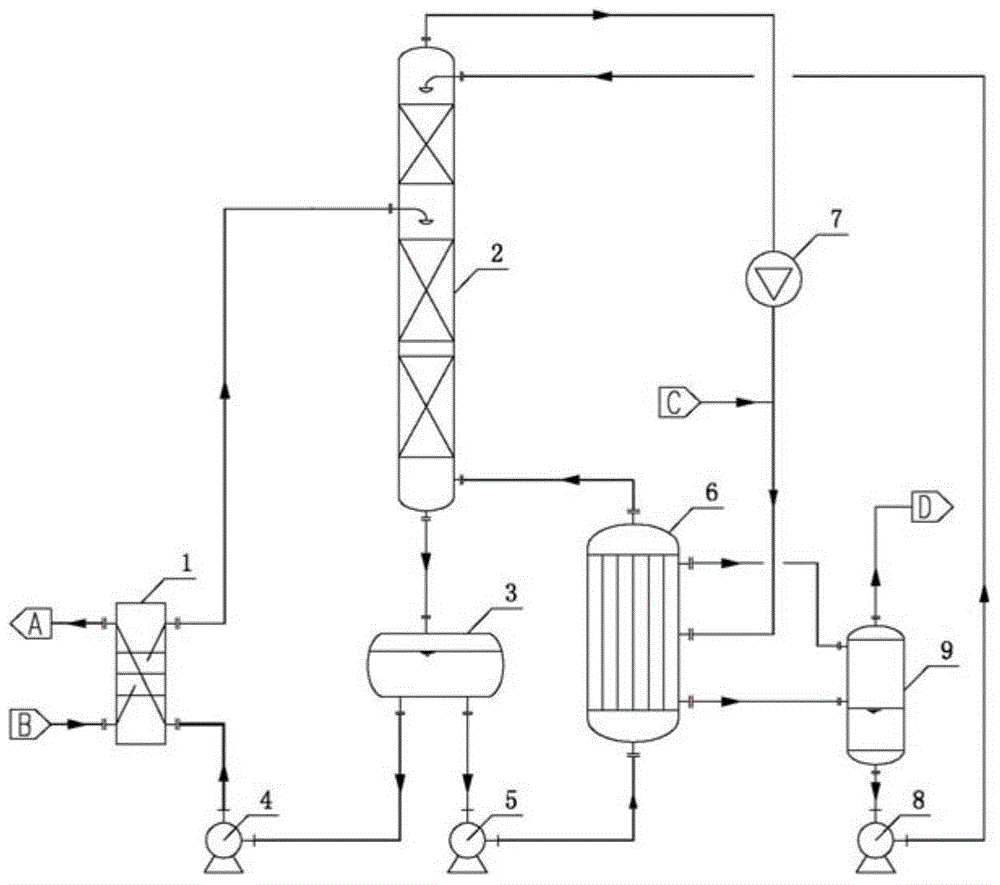

[0020] Adopt process of the present invention to handle ammonia nitrogen wastewater, ammonia nitrogen wastewater B treatment capacity is 20m 3 / h, ammonia nitrogen concentration is 4500mg / L, at first adjust the pH value of ammonia nitrogen wastewater B to 11 with sodium hydroxide solution, pump into the raw material preheater 1 to preheat and then enter the stripping section of stripping deamination tower 2 , contact with the rising steam at the bottom of the tower, and finally flow into the liquid tank 3 of the tower kettle, the ammonia in the waste water is transferred to the steam, and rises to the top of the tower with the steam, and the ammonia-containing steam at the top of the tower is extracted by the steam compressor 7 and pressurized into the re- Boiler 6, in this process, the temperature, pressure and enthalpy of ammonia-containing vapor increase; Tower still liquid circulation pump 5 makes tower still liquid in reboiler 6, the bottom of stripping deamination tower 2...

Embodiment 2

[0022] Adopt process of the present invention to process ammonia nitrogen wastewater, ammonia nitrogen wastewater B treatment capacity is 40m 3 / h, the concentration of ammonia nitrogen is 18000mg / L, and its mode of operation is the same as that of Example 1. An ammonia absorption tower is then connected to absorb with frozen pure water, and the production concentration per hour is 4 tons of strong ammonia water of 17.5%. Less than 67.5mg / L, the water and electricity consumption per ton is 9.2 degrees.

Embodiment 3

[0024] Adopt process of the present invention to process ammonia nitrogen waste water, the processing capacity of ammonia nitrogen waste water B is 10m 3 / h, ammonia nitrogen concentration is 32000mg / L, and its mode of operation is the same as embodiment 1, connects an ammonia absorption tower afterwards, absorbs with dilute sulfuric acid, and production concentration is the ammonium sulfate solution of 28.5%, and the wastewater ammonia nitrogen concentration after treatment is less than 50mg / L L, water and electricity consumption per ton is 9.8 degrees.

[0025]To sum up, with the help of the above-mentioned technical solution of the present invention, the present invention has the advantages of low operating cost, small footprint, less public works, simple process, few sets of equipment, convenient maintenance and operation management, high degree of automation, The total investment is less and so on.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com