Internal combustion locomotive electric braking energy feedback converter and control method

An energy feedback, diesel locomotive technology, applied in electric braking systems, power management, current collectors, etc., can solve the problems of low power quality, braking energy consumption, occupying locomotive space, etc., to save equipment installation space, output High power quality and the effect of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

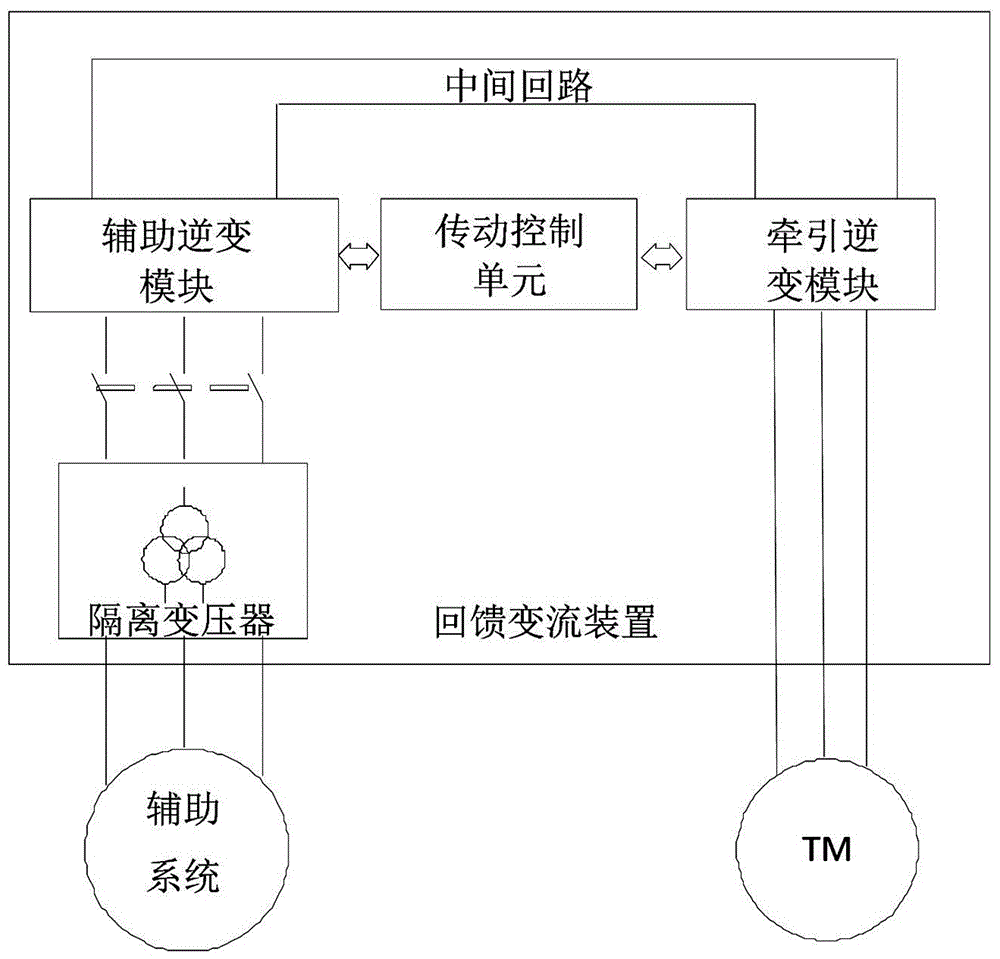

[0031] like figure 1 As shown, the diesel locomotive electric braking energy feedback converter device of this embodiment includes a traction inverter module, an auxiliary inverter module, an isolation transformer and a transmission control unit; the DC terminal of the traction inverter module communicates with the auxiliary inverter through an intermediate DC circuit. The DC terminal of the transformer module is connected; the AC terminal of the auxiliary inverter module is connected with the input side of the isolation transformer; the transmission control unit is connected with the traction inverter module and the auxiliary inverter module respectively.

[0032] In this embodiment, the transmission control unit includes a locomotive control parameter interface, a state parameter interface, and an electric energy state parameter interface. The locomotive control parameter interface is used to receive control parameters of the locomotive; The state parameter interface is used...

Embodiment 2

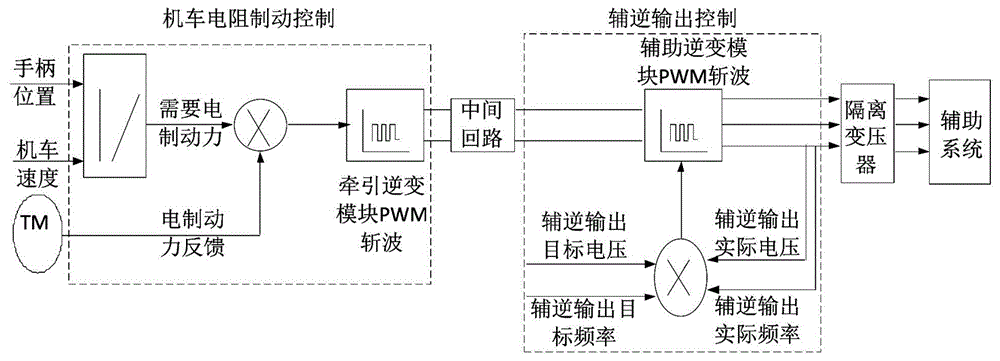

[0038]The electric braking energy feedback converter device of the diesel locomotive in this embodiment is the same as that in the first embodiment. The control method of the diesel locomotive electric braking energy feedback converter device of this embodiment is basically the same as that of Embodiment 1, the difference is that the specific steps of step S4 are: S4.2.1. Calculate the output target voltage of the auxiliary inverter module to determine the output target voltage of the auxiliary inverter module, and use the output target frequency of the isolation transformer as the output target frequency of the auxiliary inverter module; S4.2.2. The transmission control unit obtains the output actual voltage of the auxiliary inverter module and the actual output frequency of the auxiliary inverter module; S4.2.3. The transmission control unit uses the output actual voltage of the auxiliary inverter module and the output target frequency of the auxiliary inverter module accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com