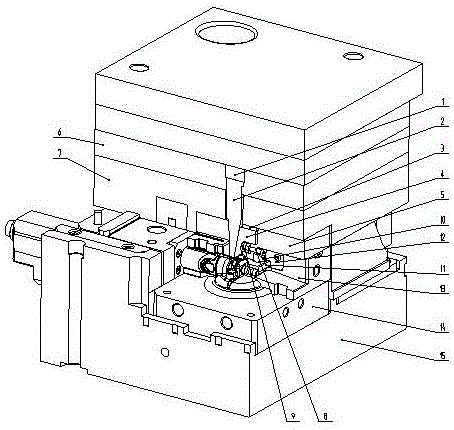

Demolding mechanism for multi-directional backoffs of plastic part of injection mold

A technology of injection mold and mold release mechanism, which is applied to the field of molding molds with multi-directional undercuts on plastic products, can solve the problems of large mold space, complex mold structure, large occupation, etc., and achieves simple and compact structure. Stable demoulding action, stable and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

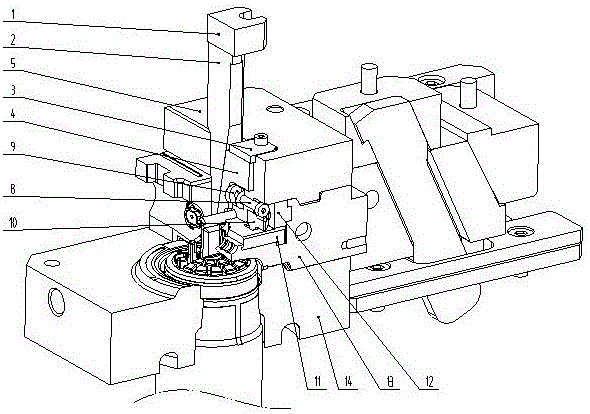

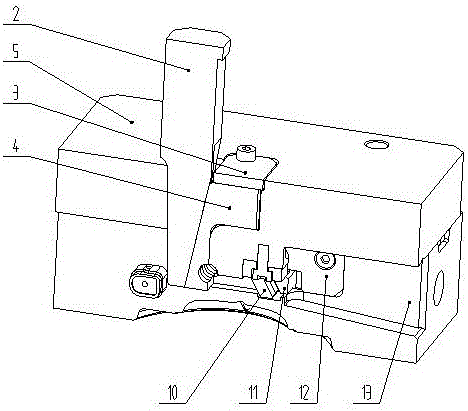

[0017] Specific embodiments of the invention will be described in detail below in conjunction with technical text and accompanying drawings.

[0018] When assembling the mould, the fixed mold first draws the block 2 and installs it in the mold cavity processed by the fixed mold floating plate 6 and is limited by the hanging table. Firstly, the 2 sides of the drawing block are contacted and pressed tightly, and the bolt passes through the first pressure plate 1 to lock and fix it with the floating plate 6 of the fixed mold; the first spring 9 is installed in the cavity processed by the insert 5 of the fixed mold, and the fixed mold slides Block 4 is installed in the mold cavity processed by fixed mold insert 5 and is limited by a hanging table. The threads processed on the sliding block 4 are tightened and assembled. The second pressure plate 3 is installed in the cavity processed by the fixed mold insert 5 and is in contact with the surface of the fixed mold sliding block 5. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com