Shaft hole interference assembly automatic press mounting device and method

A technology of press-fitting devices and shaft holes, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of large deformation of assembly parts, low yield, waste of materials, etc., and achieve high efficiency, low manufacturing cost, and overall The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

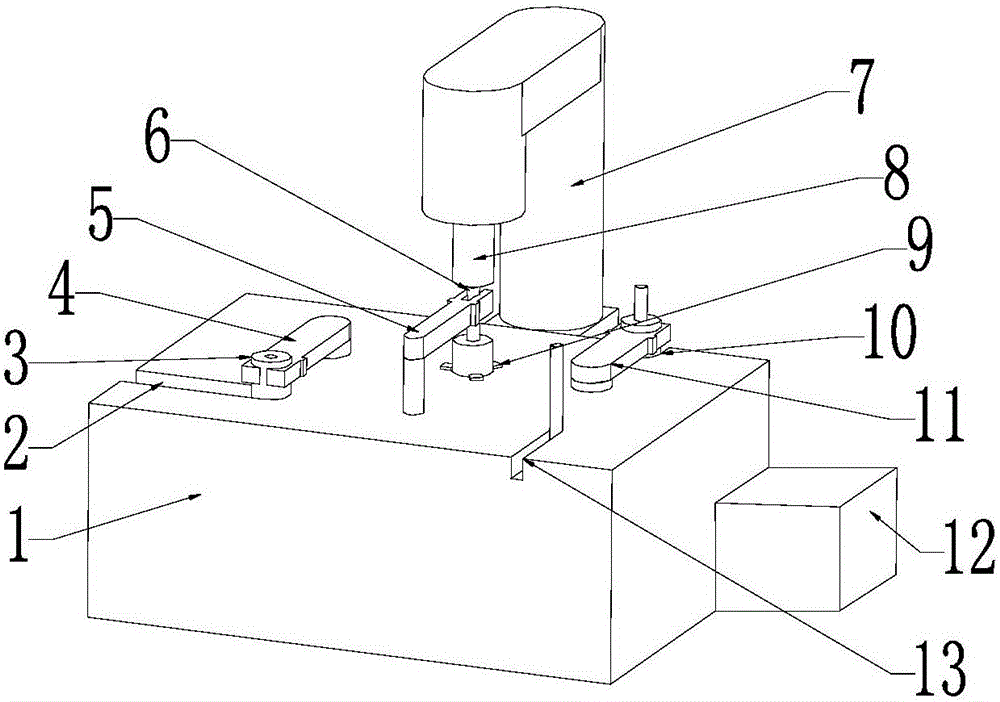

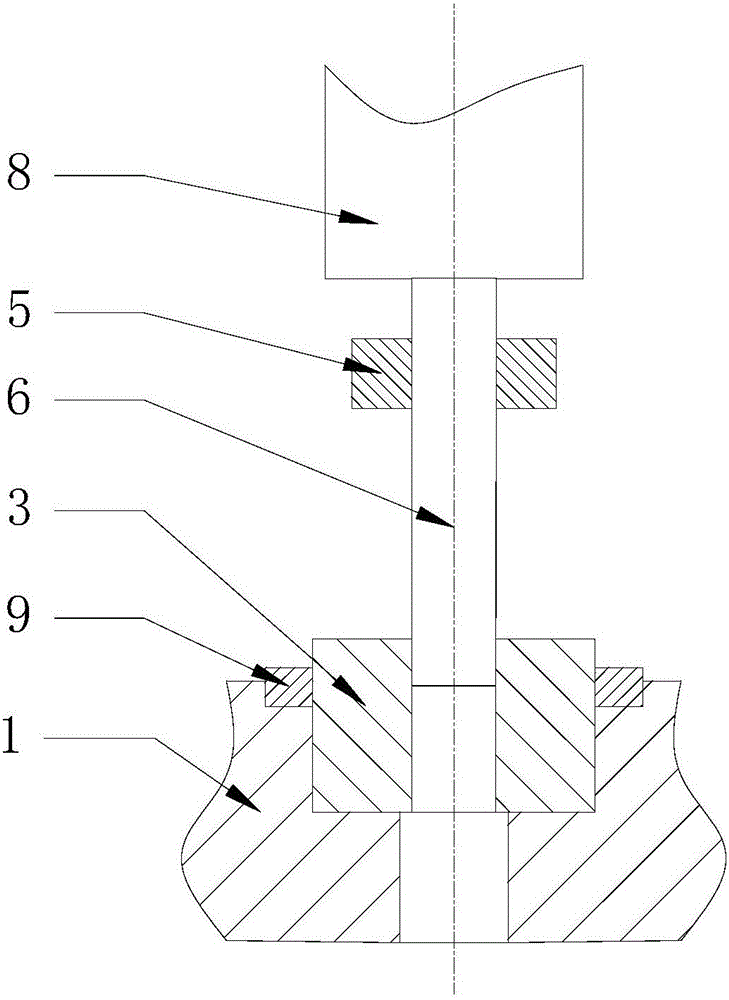

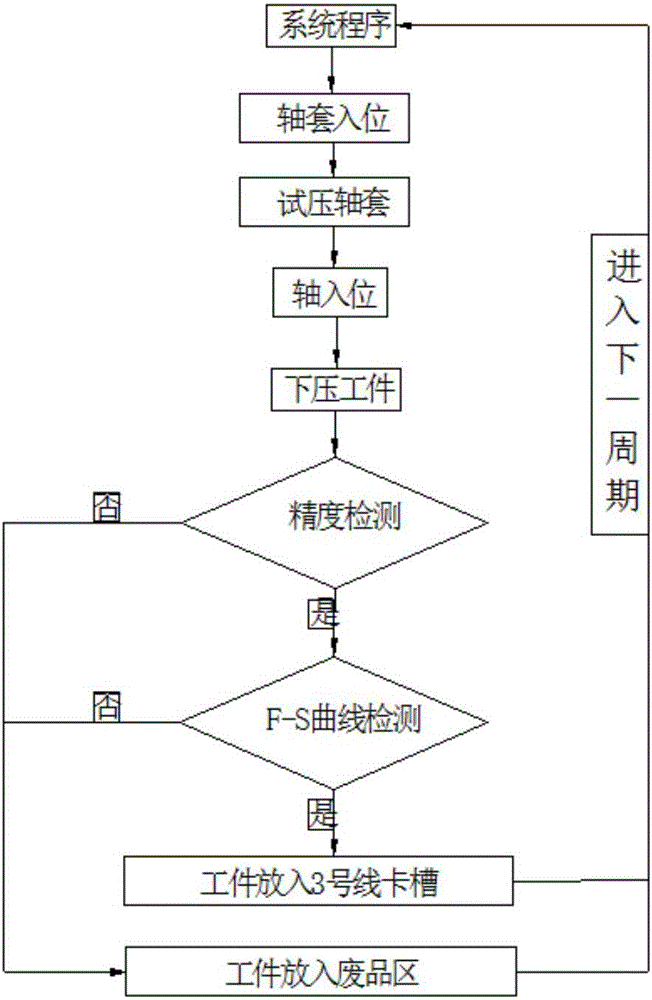

[0051] Such as figure 1As shown, the present invention discloses an automatic press-fitting device for axial hole interference assembly, which is characterized in that it includes a workbench, first to third manipulators, a three-jaw chuck, a press, a grating sensor, a multimeter, a control module, Waste recycling bin and the first to third slots on the workbench; among them, the three-jaw chuck is set in the center of the workbench to fix the shaft sleeve to be pressed; the first slot is used to place the the shaft sleeve to be pressed; the second slot is used to place the shaft to be pressed from the assembly line; the first manipulator is used to grab the shaft sleeve to be pressed in the first slot and place it on the three-jaw card In the plate, it is fixed by a three-jaw chuck; the second manipulator is used to grab the shaft to be pressed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com