Polysilsesquioxane-modified zeolite/silicone rubber composite membrane and its application

A polysilsesquioxane, silicone rubber composite membrane technology, applied in the direction of semi-permeable membrane separation, membrane technology, chemical instruments and methods, etc., can solve the threat of weakened interaction, structural stability and long-term stability of performance, Poor structural stability and other problems, to achieve the effect of improving structural and performance stability, good industrial application prospects, and stable structure and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 1) Polysilsesquioxane modified zeolite: mix octavinyl polysilsesquioxane inorganic particles, ZSM-5 zeolite with a silicon-aluminum ratio of 10, 0.1M chloroplatinic acid isopropanol solution catalyst and toluene solvent, Stir for 6 hours, filter, wash the filter cake with toluene solvent, and dry in an oven to obtain ZSM-5 zeolite modified by octavinyl polysilsesquioxane; polysilsesquioxane inorganic particles: zeolite: catalyst : The mass ratio of solvent is 0.1:10:0.1:20;

[0052] 2) Preparation of polysilsesquioxane modified zeolite / silicone rubber membrane solution: ZSM-5 zeolite, polyvinyltrimethylsiloxane, hydrogen-containing Silicone oil crosslinking agent, 0.1M chloroplatinic acid isopropanol solution catalyst and toluene solvent are mixed, stirred evenly, defoaming, and the product is obtained; wherein silicone rubber: polysilsesquioxane modified zeolite: crosslinking agent: catalyst: The mass ratio of solvent is 100:0.5:5:0.1:50;

[0053] 3) Preparation of p...

Embodiment 2

[0057] 1) Polysilsesquioxane-modified zeolite: mix octahydropolysilsesquioxane inorganic particles, TS-1 zeolite with a silicon-aluminum ratio of 300, 0.1M chloroplatinic acid isopropanol solution catalyst and acetone solvent, Stir for 0.5h, filter, wash the filter cake with acetone solvent, and dry in an oven to obtain TS-1 zeolite modified by octahydropolysilsesquioxane; wherein polysilsesquioxane inorganic particles: zeolite: The mass ratio of catalyst: solvent is 5:10:0.5:100;

[0058] 2) Preparation of polysilsesquioxane-modified zeolite / silicone rubber membrane solution: TS-1 zeolite, polyvinyltrimethylsiloxane, hydrogen-containing Silicone oil crosslinking agent, 0.1M chloroplatinic acid isopropanol solution catalyst and n-heptane solvent are mixed, stirred evenly, and defoamed to obtain the product; wherein silicone rubber: polysilsesquioxane modified zeolite: crosslinking agent: catalyst : the mass ratio of solvent is 100:60:100:5:3000;

[0059] 3) Preparation of po...

Embodiment 3

[0062] 1) Polysilsesquioxane-modified zeolite: octa[(glycidyl dimethyl)silyl]-polysilsesquioxane inorganic particles, ZSM-5 zeolite with a silicon-aluminum ratio of 600, monobutyl oxidation Mix the tin catalyst and n-hexane solvent, stir for 2 hours, filter, wash the filter cake with n-hexane solvent, and dry it in an oven to obtain octa[(glycidyl dimethyl)silyl]-polysilsesquioxane modified The final ZSM-5 zeolite; wherein the polysilsesquioxane inorganic particles: zeolite: catalyst: the mass ratio of solvent is 200:10:4:300;

[0063] 2) Preparation of polysilsesquioxane-modified zeolite / silicone rubber membrane solution: ZSM-5 zeolite modified with octa[(glycidyl dimethyl)silyl]-polysilsesquioxane in step 1, poly Mix octyltrimethylsiloxane, phenyltrimethoxysilane crosslinking agent, dibutyltin oxide catalyst and acetone solvent, stir evenly, defoam, and get it; silicone rubber: polysilsesquioxane modified After the zeolite: crosslinking agent: catalyst: the mass ratio of so...

PUM

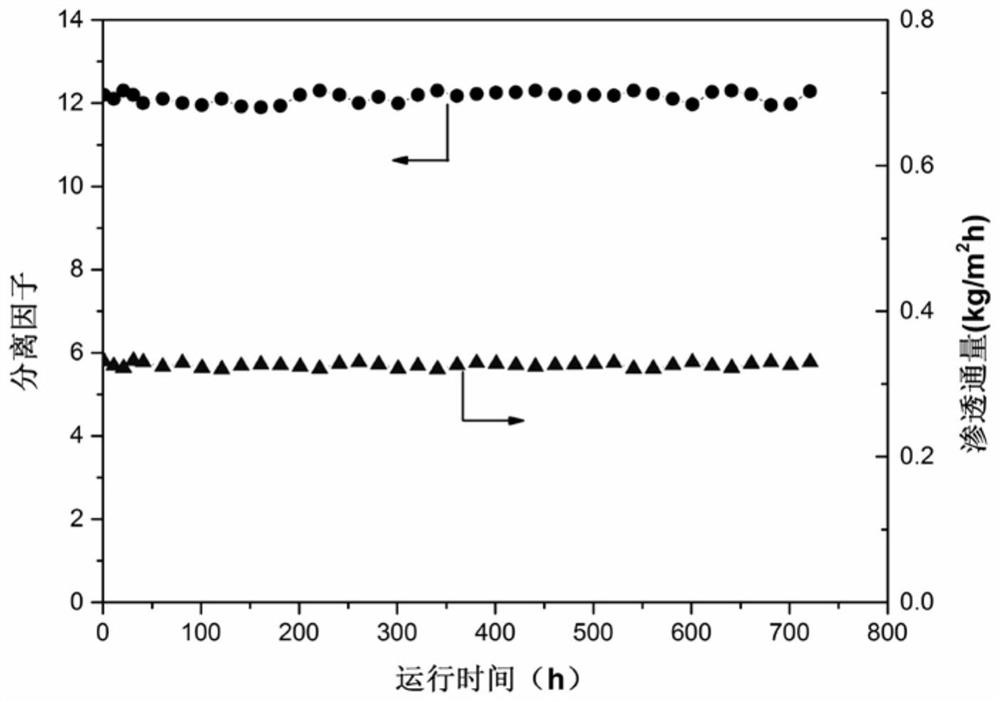

| Property | Measurement | Unit |

|---|---|---|

| separation factor | aaaaa | aaaaa |

| rate of change | aaaaa | aaaaa |

| rate of change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com