Rotenone water dispersible granule and preparation method thereof

A technology of rotenone and dispersible granules, which is applied in the field of agricultural pesticides, can solve the problems of inconvenient packaging and transportation of suspending agents, poor fluidity, sticking to walls, etc., and achieves the effects of good storage and transportation stability, good fluidity, and saving storage and transportation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

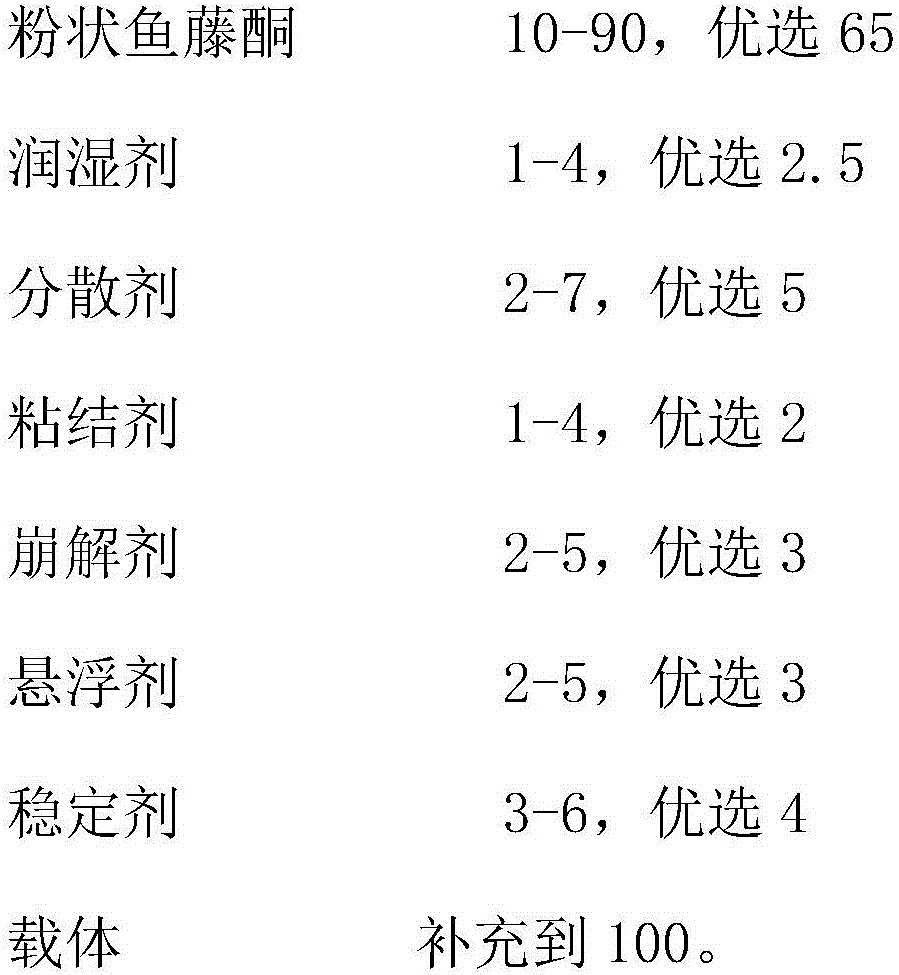

[0034] The preparation method of the rotenone water-dispersible granule is as follows: add other components to the rotenone original drug, jet-pulverize or ultra-finely pulverize, the fineness reaches 185-300 mesh, obtain wettable powder, and then carry out granulation, wherein the granulation method includes But not limited to rotating disk granulation, extrusion granulation, adjusted mixing granulation, fluid bed granulation and compression granulation.

[0035] The materials used in the present invention are all commercially available, and those skilled in the art will understand that the practice of the present invention is not limited to these sources.

Embodiment 1

[0051] Embodiment 1: preparation of rotenone water-dispersible granules

[0052]Take 10g of the original drug of rotenone, 2.5g of sodium lauryl sulfate; 5g of lauryl polyoxyethylene ether phosphate C1618; 2g of powdered polyvinyl alcohol; 3g of bentonite Darun; 3g of Darun pesticide dispersant 600C, succinic acid 4g; kaolin 69.5g; after mixing, pulverize through a jet mill to make a powder (250 mesh), then extrude and granulate to obtain 10% rotenone water-dispersible granules (sample 1).

[0053] Take 30g of the original drug of rotenone, 2.5g of sodium lauryl sulfate; 5g of lauryl polyoxyethylene ether phosphate C1618; 2g of powdered polyvinyl alcohol; 3g of bentonite Darun; 3g of Darun pesticide dispersant 600C, succinic acid 4g; kaolin 49.5g; after mixing, pulverize through a jet mill to make a powder (250 mesh), then extrude and granulate to obtain 30% rotenone water-dispersible granules (sample 2).

[0054] Take 50g of rotenone original drug, 2.5g of sodium lauryl sulf...

Embodiment 2

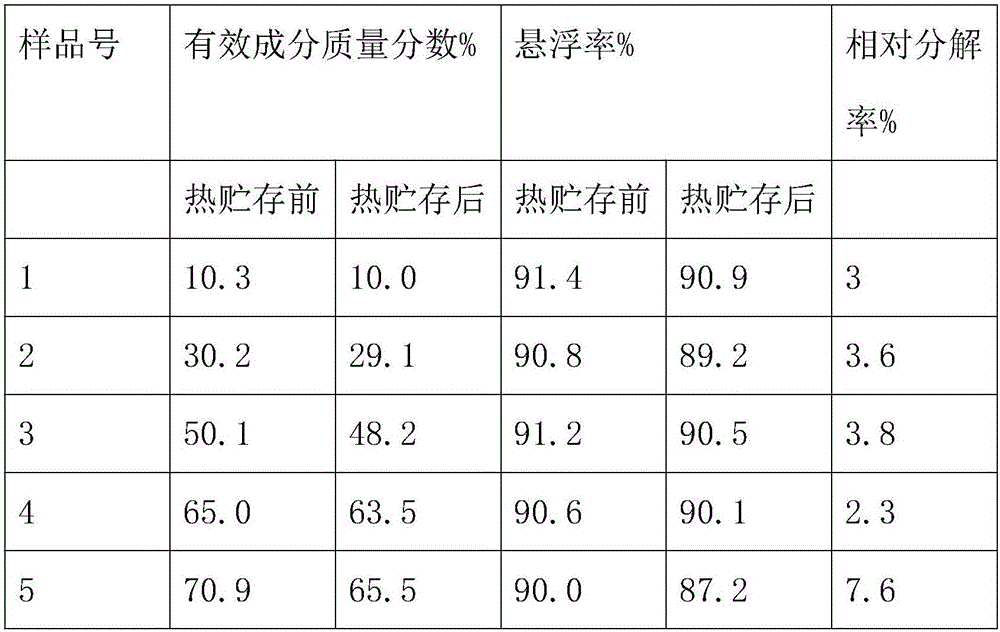

[0057] Embodiment 2: thermal storage stability test

[0058] The rotenone water-dispersible granules (samples 1-5) of various concentrations mentioned above were taken for thermal storage stability test. Thereafter, the active ingredients of each sample were measured and tabulated below. All samples were performed in triplicate and the values were averaged.

[0059] result:

[0060] Table 1: Thermal storage stability.

[0061]

[0062] The relative decomposition rate generally tends to increase with the concentration, but the relative decomposition rate of 65% rotenone water-dispersible granules is obviously higher than other samples.

[0063] Example 2: Dust Test

[0064] The above-mentioned samples 1-5 were taken for dust test, and all samples were carried out in triplicate, and the values were averaged. The test results are as follows:

[0065]

[0066]

[0067] According to the Chinese standards for the determination of granular pesticide dust (GB / T 3036...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com