QLED, manufacturing method therefor and illuminating device

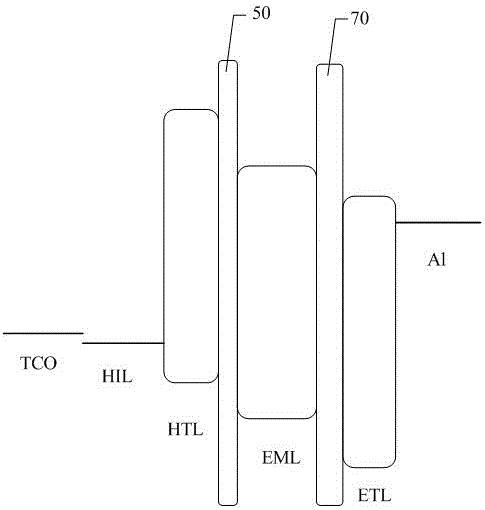

A quantum dot light-emitting and insulating layer technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problem that the performance of QLED needs to be improved, and achieve the effect of increasing the recombination probability and improving the overall efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

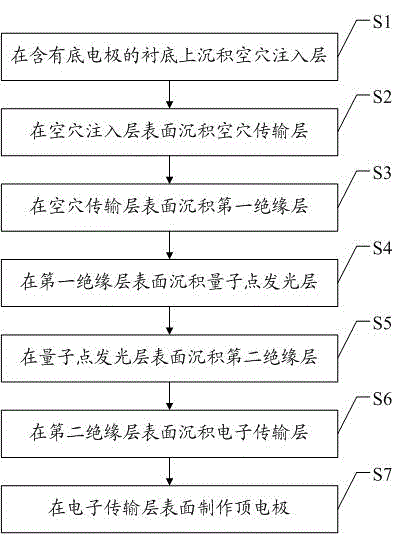

[0059] 1) The glass substrate containing ITO (120nm) was subjected to cleaning agent, acetone, IPA (isopropanol) and deionized water for 15 minutes, then dried, and treated with ozone plasma for 10 minutes;

[0060] 2) Depositing a hole injection layer on the glass substrate, the material of the hole injection layer is PEDOT:PSS (thickness 40nm), and then heating at 150°C for 15 minutes;

[0061] 3) Deposit a hole transport layer on the hole injection layer. The material of the hole transport layer is TFB with a thickness of 25nm. Specifically, it is spin-coated in a glove box to form a film, and then heated at 150°C for 30 minute;

[0062] 4) Depositing a first insulating layer on the hole transport layer, the material of the first insulating layer is PMMA, the thickness is 5nm, the solvent is acetone solution, and heated at 50°C for 10 minutes after film formation;

[0063] 5) Deposit a quantum dot light-emitting layer on the first insulating layer, the material of the quan...

Embodiment 2

[0068] 1) The glass substrate containing ITO (120nm) was subjected to cleaning agent, acetone, IPA (isopropanol) and deionized water for 15 minutes, then dried, and treated with ozone plasma for 10 minutes;

[0069] 2) Depositing a hole injection layer on the glass substrate, the material of the hole injection layer is PEDOT:PSS (thickness 40nm), and then heating at 150°C for 15 minutes;

[0070] 3) Deposit a hole transport layer on the hole injection layer. The material of the hole transport layer is TFB with a thickness of 25nm. Specifically, it is spin-coated in a glove box to form a film, and then heated at 150°C for 30 minute;

[0071] 4) Depositing a first insulating layer on the hole transport layer, the material of the first insulating layer is SiO 2 , the thickness is 5nm, the sol solution is spin-coated to form a film, and heated at 150°C for 30 minutes after the film is formed;

[0072] 5) Deposit a quantum dot light-emitting layer on the first insulating layer, t...

Embodiment 3

[0077] 1) The glass substrate containing ITO (120nm) was subjected to cleaning agent, acetone, IPA (isopropanol) and deionized water for 15 minutes, then dried, and treated with ozone plasma for 10 minutes;

[0078] 2) Depositing a hole injection layer on the glass substrate, the material of the hole injection layer is PEDOT:PSS (thickness 40nm), and then heating at 150°C for 15 minutes;

[0079] 3) Deposit a hole transport layer on the hole injection layer. The material of the hole transport layer is TFB with a thickness of 25nm. Specifically, it is spin-coated in a glove box to form a film, and then heated at 150°C for 30 minute;

[0080] 4) Depositing a first insulating layer on the hole transport layer, the material of the first insulating layer is PMMA, the thickness is 8nm, the solvent is acetone solution, and heated at 50°C for 10 minutes after film formation;

[0081] 5) Depositing a quantum dot light-emitting layer on the first insulating layer, the material of the q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com