Tempering hardness conversion method of P92 steel

A technology of tempering hardness and hardness, applied in the field of heat treatment of P92 steel, can solve the problems of damage to the workpiece, the influence of other factors such as steel grades, and the deviation of hardness conversion, to achieve the effect of reducing differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The present embodiment provides a tempering hardness conversion method of P92 steel, which comprises the following steps:

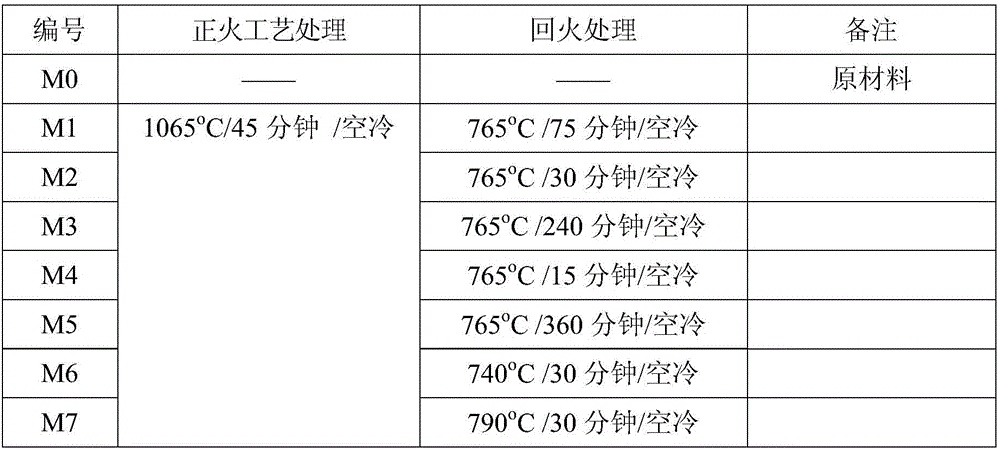

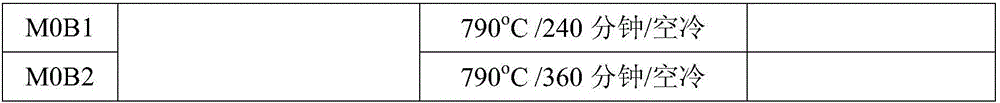

[0024] (1), at the same position of P92 steel pipe, intercept a plurality of test pieces (10 test pieces in total in the embodiment, respectively marked as M0-M7, M0B1, M0B2), the thickness of the test piece is 30mm; After the normalizing process, the tempering temperature and time are adjusted to perform different tempering treatments to obtain P92 steel specimens with different tempering hardness; the heat treatment parameters of the above ten specimens are as follows 1.

[0025] Table 1

[0026]

[0027]

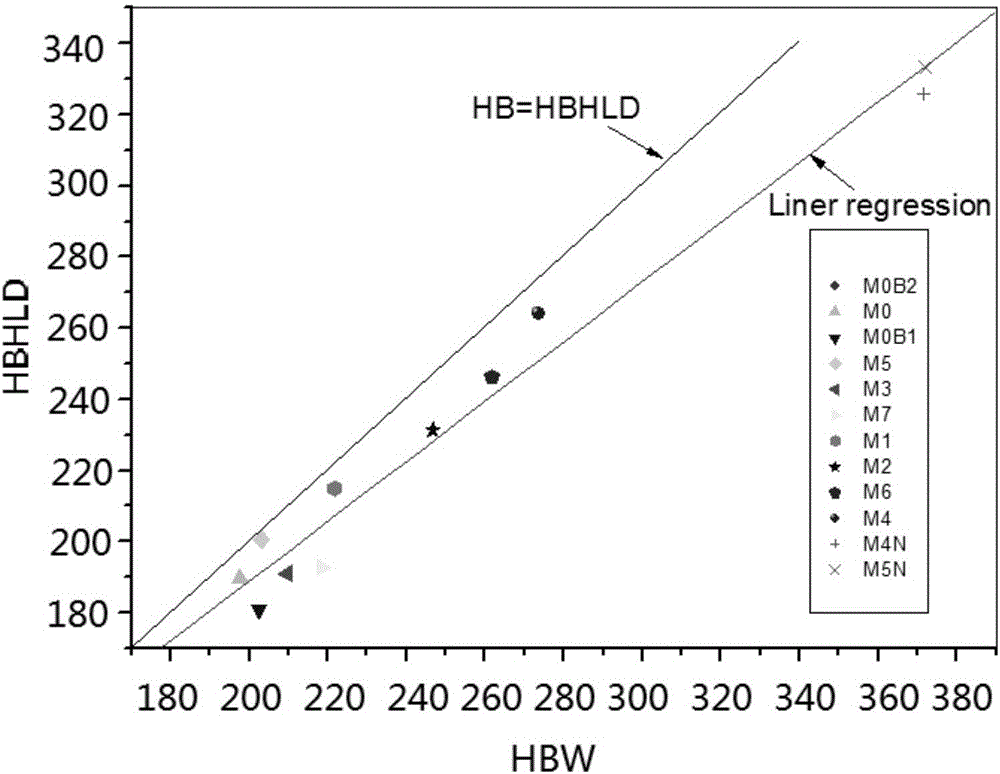

[0028] (2), after carrying out normalizing process treatment and tempering treatment, after adopting sandpaper and polishing machine to carry out grinding and polishing respectively to the P92 steel specimen surface that step (1) obtains, adopt desktop Brinell hardness tester to measure this P92 The actual Brinell hardness (HBW) of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com