Mounting flange structure and preparation method of spherical pressure vessel installed at equator

A technology for pressure vessels and mounting flanges, which is applied in the field of equator-mounted spherical pressure vessel mounting flange structures and its preparation, can solve the problem of not being able to use the Alphabus satellite platform installation method, unable to meet the requirements of general assembly layout and mechanical environment adaptability, and unable to Realize equatorial flange installation and other problems, and achieve the effect of strong adaptability to mechanical environment, light weight and high adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

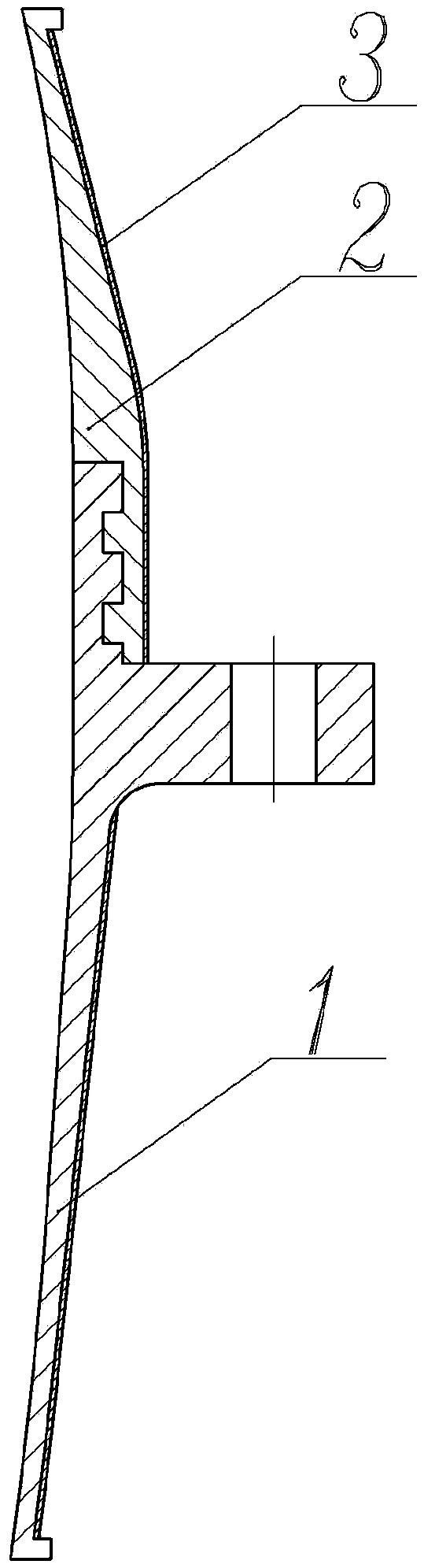

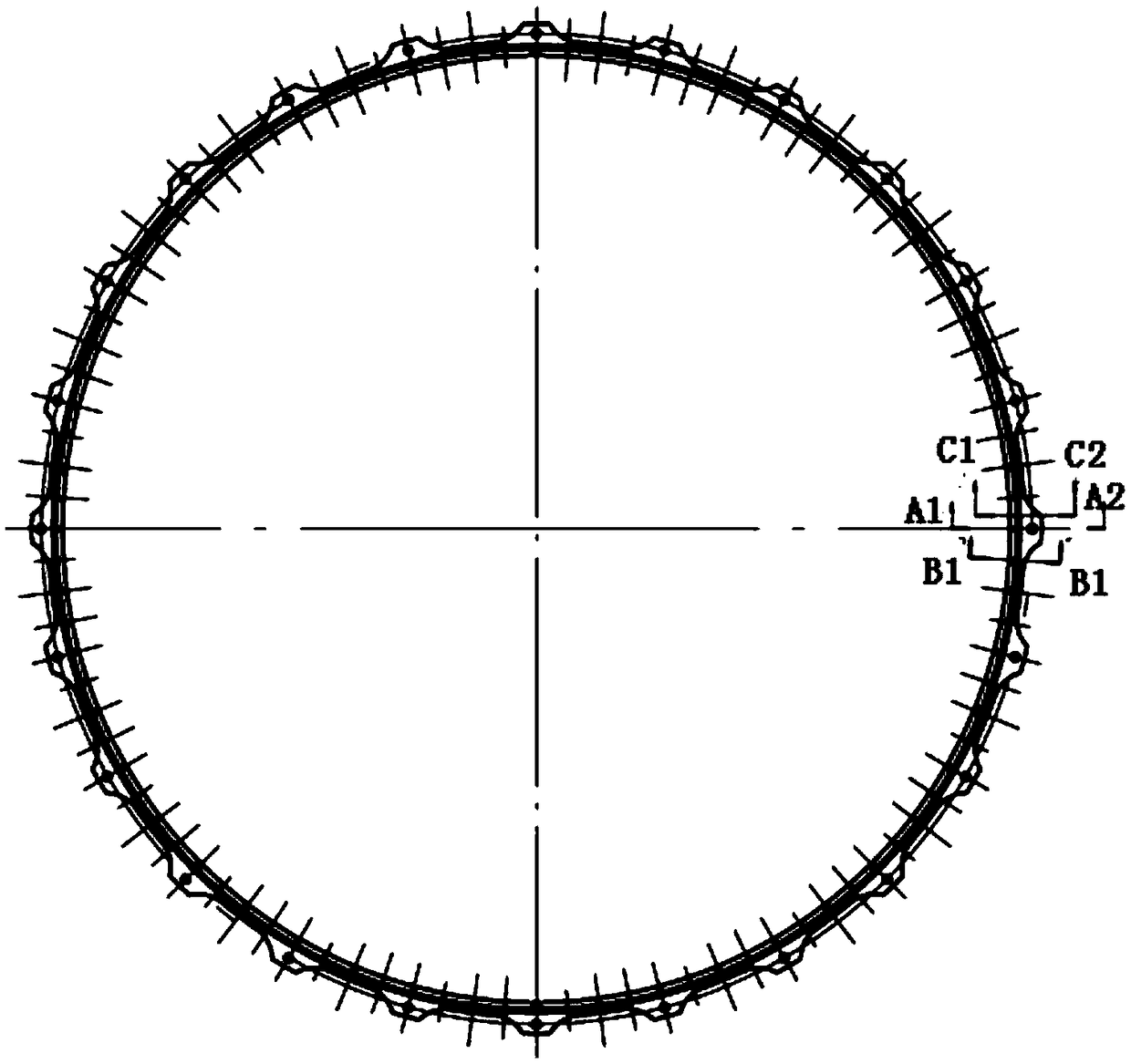

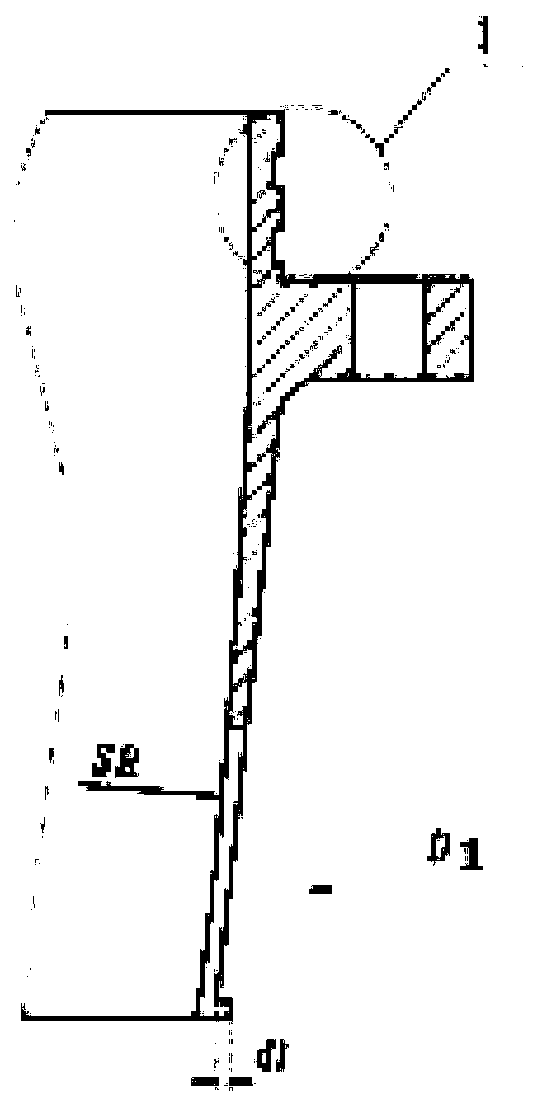

[0042] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0043] Such as figure 1 , Figures 2A-2F , Figures 3A-3F As shown, the present invention discloses a mounting flange structure for an equator-mounted spherical pressure vessel, which includes a lower flange 1, an upper flange 2, and a composite material layer 3, the lower flange 1 is connected to the upper flange 2, and the composite material layer 3 is wound on the outer surface of the lower flange 1 and the outer surface of the upper flange 2 .

[0044] The lower flange 1 is a thin-walled integral ring structure, which is simple in structure and low in cost.

[0045] The upper flange 2 is a thin-walled semi-ring structure, which is simple in structure and low in cost.

[0046] The inner profile of the lower flange 1 and the upper flange 2 matches the outer profile of the composite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com