Adapter substitute connector and connecting system

A technology for converting joints and connectors, which is used in adjustable connections, pipes/pipe joints/pipe fittings, pipe supports, etc. problems, to achieve the effect of low risk, low staff operation intensity, and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

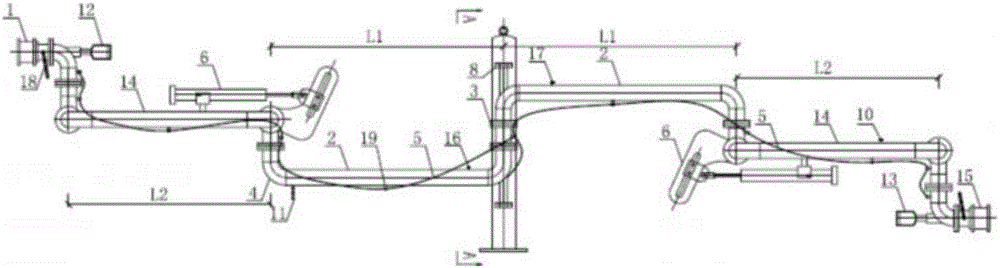

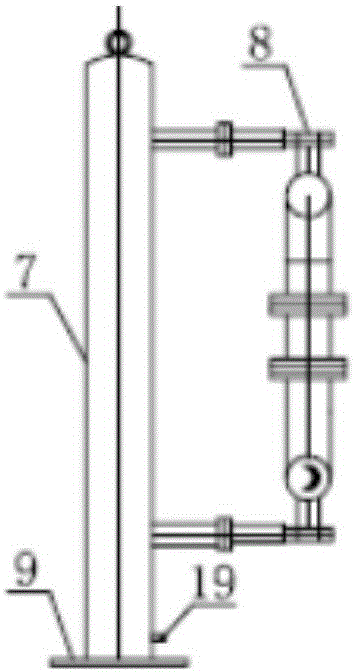

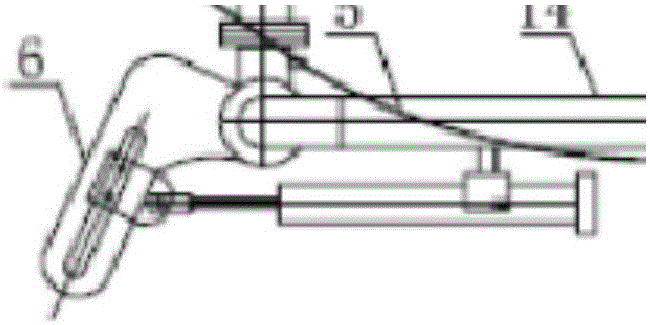

[0039] figure 1 Schematic diagram of the structure of the conversion joint connector provided by the embodiment of the present invention; figure 2 A schematic side view of the column 7 of the conversion joint connector provided by the embodiment of the present invention; image 3 A schematic structural view of the balance system 6 of the conversion joint connector provided by the embodiment of the present invention; Figure 4 A schematic diagram of the structure between the elbow 4 and the adjusting arm 14 of the conversion joint connector provided by the embodiment of the present invention. Such as Figure 1 to Figure 4 As shown, the conversion joint connector provided by the present invention includes: a connecting pipe 2, a column 7, two adjustment arms 14 and a joint; 6 rotates, the balance system 6 drives the two ends of the adjustment arm 14 to move up and down; that is, one end of the adjustment arm 14 is connected to the joint, and the other end is connected to the...

Embodiment 2

[0053] Further, the supporter 8 is a telescopic sleeve rod, the telescopic sleeve rod includes a fixed rod and a sliding rod slidably arranged in the fixed rod, the fixed rod is fixedly arranged on the column 7, and the sliding rod Connect with the connecting pipe 2. The supporter 8 can drive the connecting pipe 2 along the figure 1 Move the position perpendicular to the direction of the paper.

[0054] The connecting pipe 2 is also two sections, the sliding rod is connected with the end of the connecting pipe 2, and the two ends of the two connecting pipes 2 are connected by a rotary joint 3.

[0055] In the second embodiment, a sensor for detecting poisonous gas can be provided on the adjusting arm 14 according to the requirement. When the sensor detects poisonous gas or leakage, the signal can be transmitted to the controller, and the controller controls the alarm to give an alarm, which can increase the safety performance of use. , to reduce losses. All the other are th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com