Connecting structure of main shaft and rotor and integrated rolling rotor compressor

A technology of connecting structure and rolling rotor, applied in the field of compressors, can solve the problem that the crankshaft and the rotor cannot be fastened.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

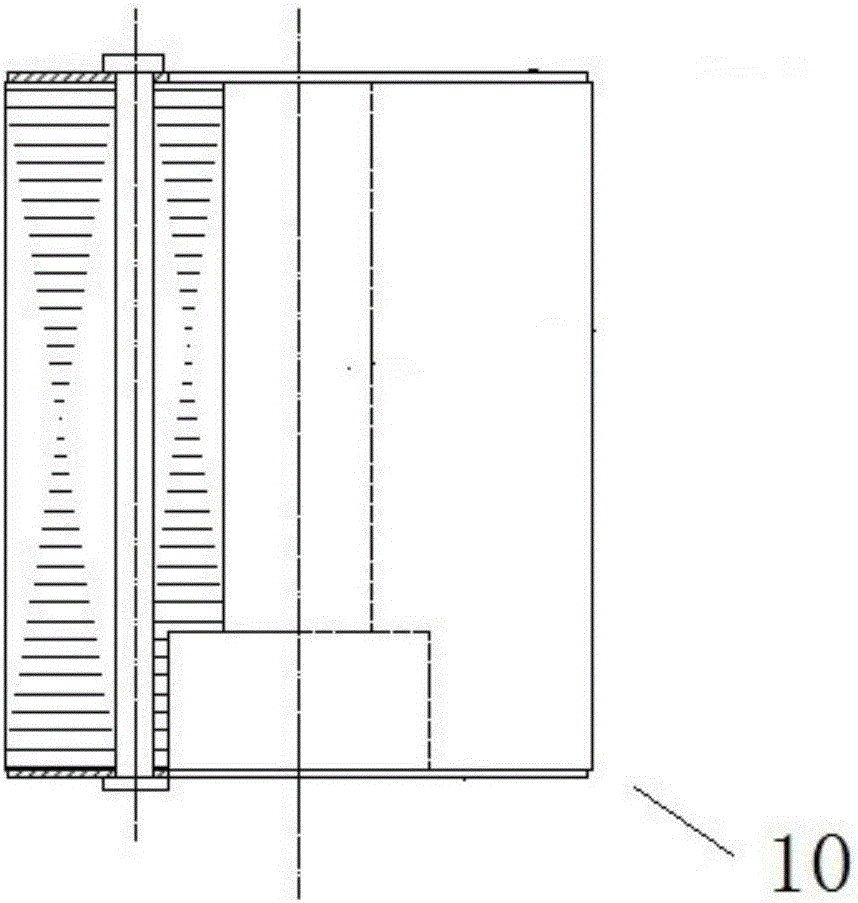

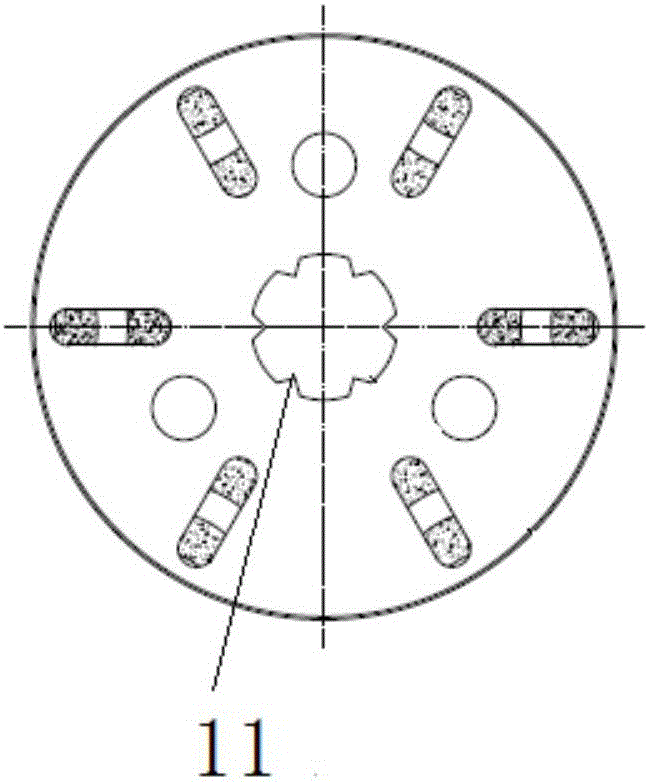

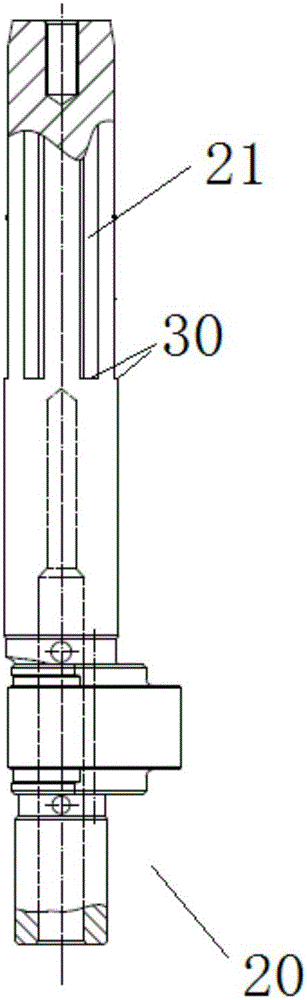

[0038] This embodiment provides a connection structure between the main shaft and the rotor of an integrated rolling rotor compressor, such as Figure 6 As shown, it includes: a rotor 10 and a main shaft 20, the circumferential wall of the main shaft 20 is provided with a circumferential fixing part that cooperates with the concave and convex inner wall of the rotor 10; the end surface of the main shaft 20 is provided with a 10 axial fixing members. The circumferential fixing part and the axial fixing member make the main shaft 20 and the rotor 10 fastened not only in the circumferential direction, but also in the axial direction, so as to prevent the rotor 10 and the main shaft 20 from being damaged during the rotation of the main shaft 20 and the rotor 10. Relative movement along the axial direction separates from each other.

[0039] Axial fixing components include: such as Figure 6 As shown in , the baffle 40 for restricting the axial movement of the rotor 10 relative t...

Embodiment 2

[0048] The connection structure between the main shaft and the rotor of an integrated rolling rotor compressor provided in this embodiment includes: a rotor 10 and a main shaft 20, the circumferential wall of the main shaft 20 is axially extended and formed with convex teeth, and the inner circular wall of the rotor 10 Grooves are formed on the top to cooperate with the convex teeth, and the cooperation between the convex teeth and the grooves realizes the fastening and linkage setting of the main shaft 20 and the rotor 10 in the circumferential direction, so that when the rotor 10 rotates, the main shaft 20 can be driven to be linked to realize The linkage between the motor output shaft and the compressor crankshaft. An axial fixing member for axially fixing the rotor 10 is arranged on the end surface of the main shaft 20 . Therefore, the main shaft 20 and the rotor 10 are fastened not only in the circumferential direction, but also in the axial direction, so as to prevent th...

Embodiment 3

[0051] An integrated rolling rotor compressor provided in this embodiment includes a motor part and a compressor part, and the two parts are connected together through a main shaft 20 that is used as both the output shaft of the motor and the crankshaft of the compressor, such as Figure 6 As shown, the connection structure between the main shaft 20 and the rotor 10 is the connection structure described in the above-mentioned embodiment 1 or embodiment 2, so it has all the advantages of the above-mentioned embodiment 1 or embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com