Coal seam hydraulic pressure jetting breathability-improving system and construction method thereof

A construction method and technology above the coal seam, applied in the direction of earthwork drilling, gas discharge, mining fluid, etc., can solve the problems of not being able to ensure the full overflow of gas gas, affecting the construction period of coal mines, increasing air permeability, etc., and reaching the range of pre-pumping efficiency wide, improve gas drainage efficiency, and increase air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

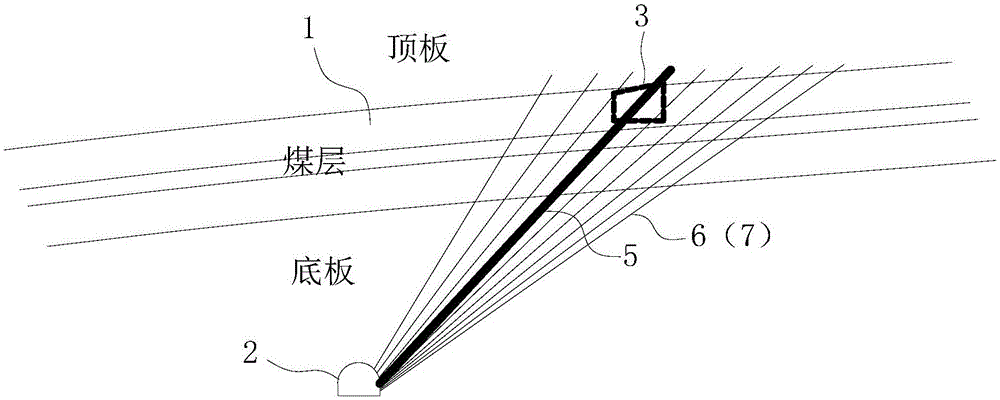

[0027] like figure 1 , 2 As shown, a coal seam hydraulic pressure punching anti-permeability system includes a floor roadway 2 located below the coal seam 1, and a plurality of boreholes 7 are set radially in the floor roadway 2 toward the coal seam 1, and the boreholes 7 extend to In the roof above the coal seam 1, the parts of the boreholes 7 in the coal seam 1 are located within 40 meters on both sides of the driving strip 3 of the coal seam 1; a plurality of flushing holes are arranged at intervals between the boreholes 7 6 and fracturing holes 5, each of the fracturing holes 5 passes through the excavation strip 3, and each fracturing hole 5 is arranged at intervals in a line along the extension direction of the excavation strip 3; the fracturing holes 5 The opening is closed and the fracturing hole 5 is provided with a high-pressure water injection device, and the flushing hole 6 is provided with a flushing drill bit 10 . The above-mentioned excavation strip 3 refers t...

Embodiment 2

[0033] A construction method of the hydraulic pressure punching anti-permeability system of the coal seam 1, comprising the following steps:

[0034] Step 1: Transport the drilling rig to the floor tunnel 2, and lay the water supply pipeline and drainage pipeline in the floor tunnel 2;

[0035] Step 2: Drilling 7, calculating the position of the opening of the drilling 7 and the angle of the drilling 7, using the drilling rig to carry out the construction of the drilling 7, ensuring that the parts of each drilling 7 in the coal seam 1 are located on both sides 40 of the driving strip 3 of the coal seam 1 within meters;

[0036] Step 3: Select a drill hole 7 passing through the excavation strip 3 at intervals of 80-120m along the extension direction of the excavation strip 3 as the fracturing hole 5, and seal the fracturing hole 5 and perform water injection construction. The water injection pressure is 15-30Mpa, keep the pressure for 2-4 days after water injection, during thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com