Method for Improving Steam Equalization in Steam Flooding Oil Recovery Process and Steam Flooding Oil Recovery System

An oil production system and steam flooding technology, which is applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc., can solve problems such as oil recovery that affects the overall effect of steam thermal recovery, and the inability to expand the steam chamber in a balanced manner, so as to improve the The effect of steam balance, improving production degree and improving oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

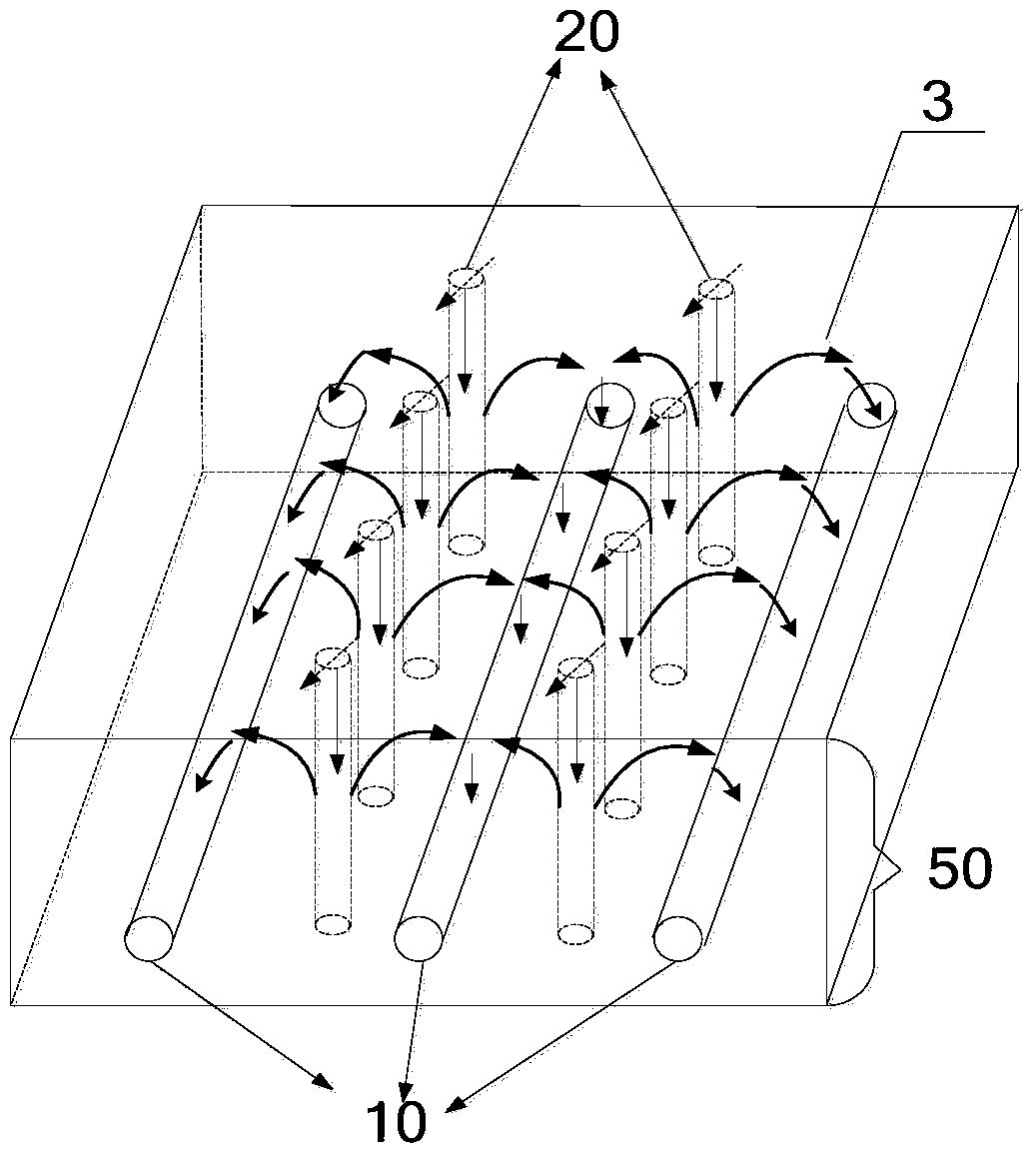

Embodiment 1

[0041] In September 2011, the Chong 32 well area of Fengcheng Oilfield in Xinjiang carried out steam flooding oil recovery of vertical wells with small well spacing. (19~20°C) The viscosity of crude oil is 600016mPa.s. In the 8th round of oil recovery, the steam stimulation was transferred to steam flooding. Using the method for improving the steam balance in the steam flooding oil recovery process of the present invention, the steam flooding stage was produced for 30 months. It was found through testing that the increased recovery degree of the steam flooding stage was 16.6 %, the accumulative recovery degree in steam huff and puff and steam flooding stages is 53.1%, the oil-steam ratio is 0.09, the monthly decline rate in oil production stage is 0.4%, and the annual decline rate in oil production stage is 4.7%.

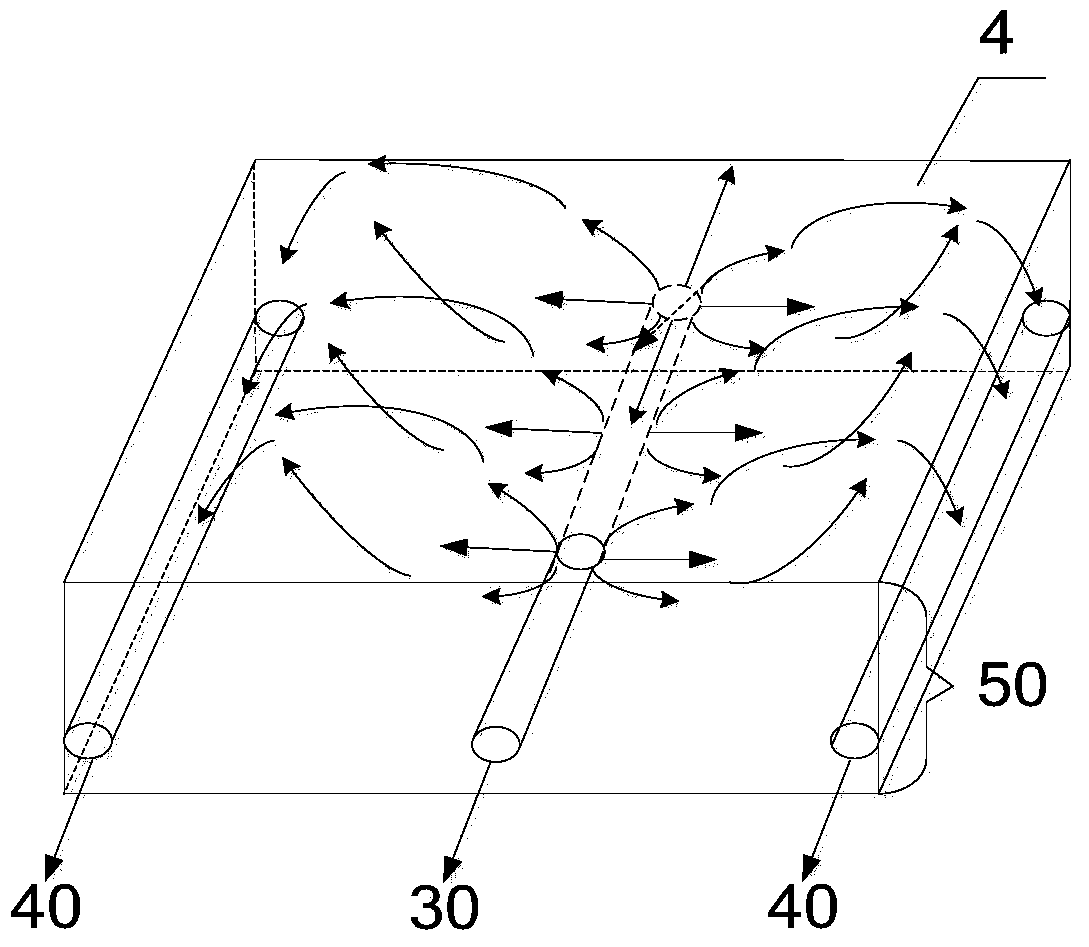

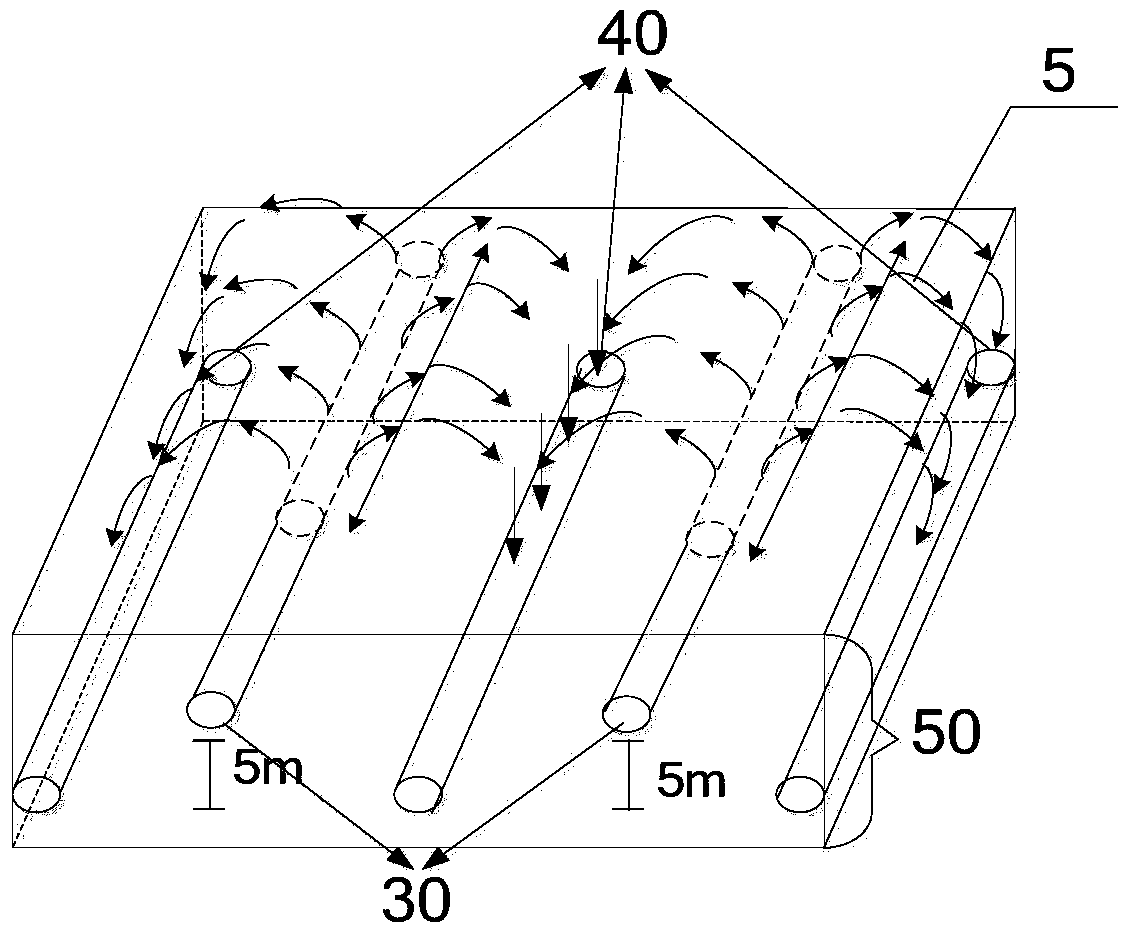

Embodiment 2

[0043] Vertical well-horizontal well (VHSD) was carried out in Zhong 32 well area of Fengcheng Oilfield in Xinjiang in August 2013. The reservoir validity is 15.8m, the porosity is 32%, the permeability is 3012mD, the oil saturation is 74.6%, and the formation temperature Under low temperature (19~20℃) the viscosity of crude oil is 631556mPa.s. In the 8.4 round of oil recovery, the steam huff and puff of the vertical well is transferred to steam flooding, and in the 7.6 round of oil recovery, the steam huff and puff of the horizontal well is transferred to steam flooding, and the method for improving the steam balance in the steam flooding oil recovery process of the present invention is transferred to After steam flooding, the daily oil production increased from 69t / d before steam flooding to 115t / d, and the oil-steam ratio increased from 0.11 to 0.18. The steam flooding stage produced 12 months, and the recovery degree of the steam flooding stage reached 4.5%.

[0044] Fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com