Preparation method of high-performance rubber

A high-performance, rubber technology, applied in the field of material synthesis, can solve the problems of mutual repulsion and difficult dispersion, and achieve the effect of reducing the dosage, reducing the dosage, and avoiding the gel or scorch of the rubber compound.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. According to the mass ratio mKOH:m carbon nanotube:m zinc stearate=1:10:7, weigh 10gKOH, 100g carbon nanotube and 70g zinc stearate;

[0035] 2. Add KOH, carbon nanotubes and zinc stearate to the vacuum mixer respectively;

[0036] 3. Vacuumize the equipment until the internal pressure of the equipment is -0.1MPa, and start the stirring equipment at the same time to obtain the mixed material;

[0037] 4. Send the mixed material into the rotary furnace, feed N2 into the rotary furnace, raise the temperature to 900°C at the same time, keep it warm for 2 hours, and cool the material to room temperature in N2 protection to obtain a reinforced composite material;

[0038] 5. Add the raw rubber to the raw rubber in the compounding link to obtain the masterbatch;

[0039] 6. After the master batch is vulcanized, high-performance rubber products are obtained.

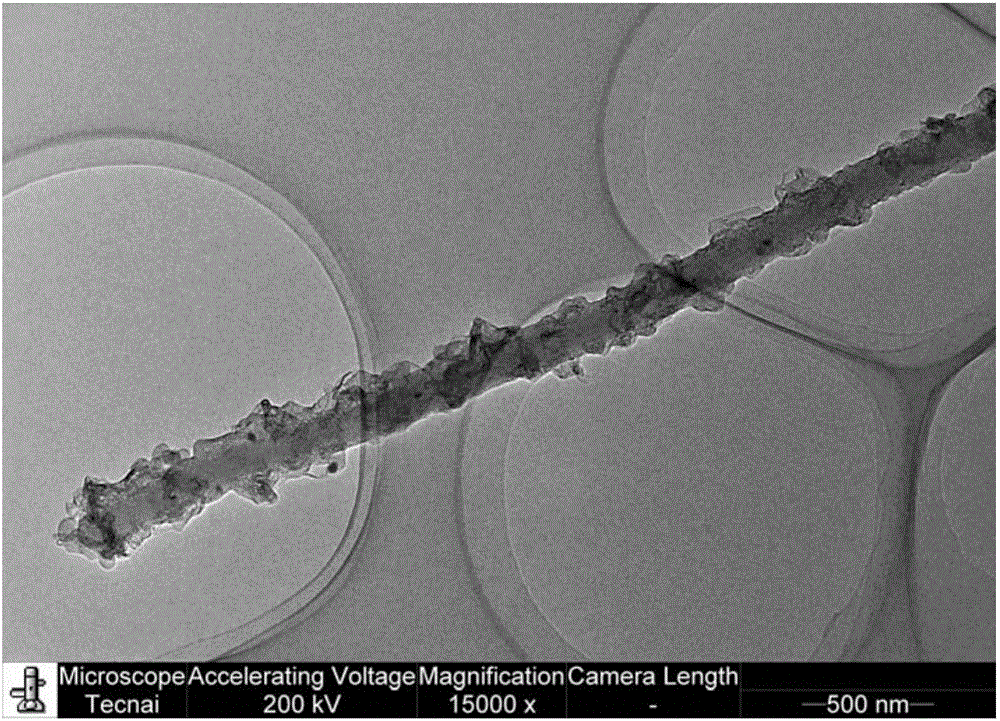

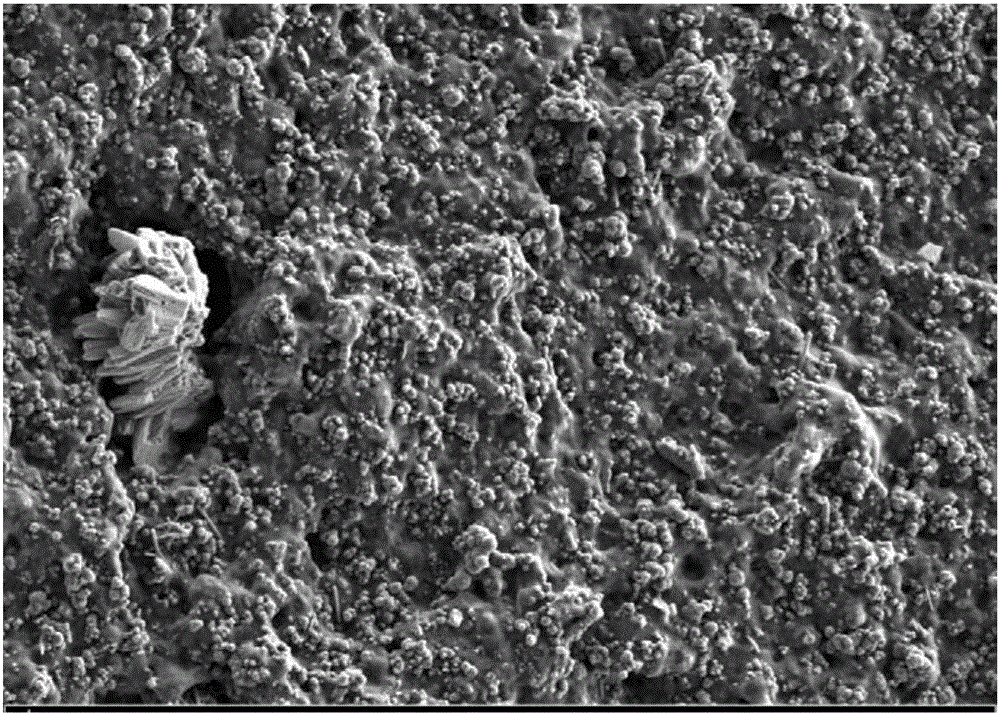

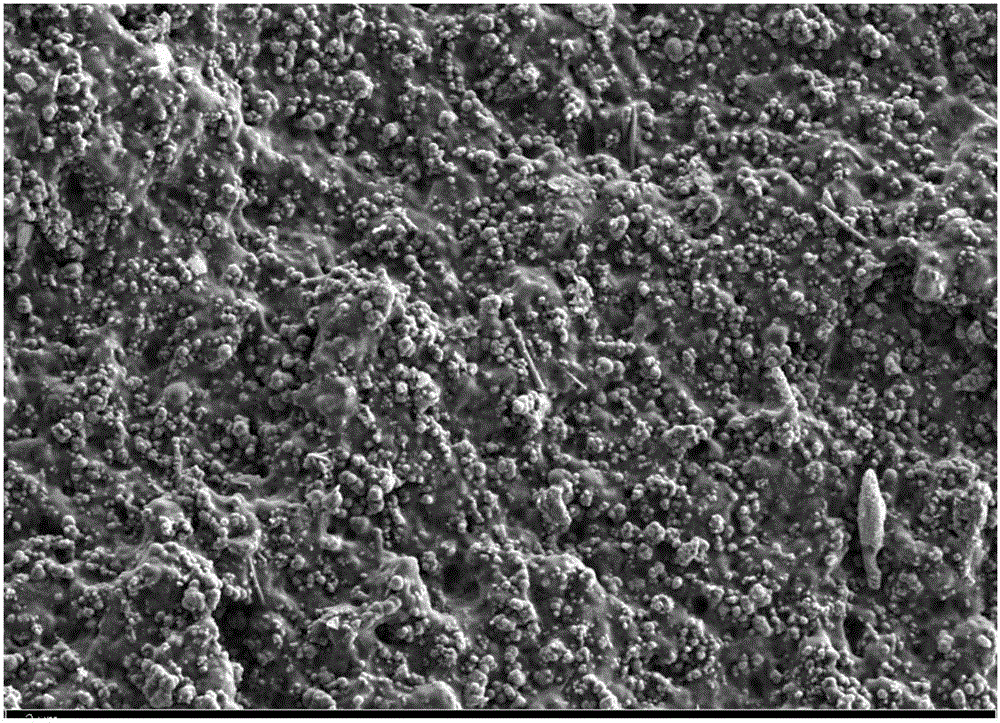

[0040] figure 1 It is a TEM photo of the reinforced composite material. It can be seen from Figure 2 that zinc o...

Embodiment 2

[0044] 1. According to the mass ratio m zinc acetate: m carbon nanotube: m water = 1:5: 14~24, weigh 10g zinc acetate, 50g carbon nanotube and 150g water, put it into the stirring device, stir at 50rpm for 1.0h, Obtain a slurry in which the materials are uniformly mixed;

[0045] 2. The slurry is dried by spray drying equipment to obtain a solid mixture. The spray drying conditions are as follows: the inlet temperature of the spray dryer is 190°C, the outlet temperature is 170°C, and the rotation speed of the peristaltic pump is 30rpm.

[0046] 3. Transport the solid mixture to a rotary furnace with a furnace temperature of 460°C, and treat it at a constant temperature for 4 hours. After the material is cooled, a reinforced composite material is obtained;

[0047] 4. The reinforced composite material is added to the raw rubber and mixed in the rubber mixing process to obtain the master batch;

[0048] 5. After the master batch is vulcanized, high-performance rubber products a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com