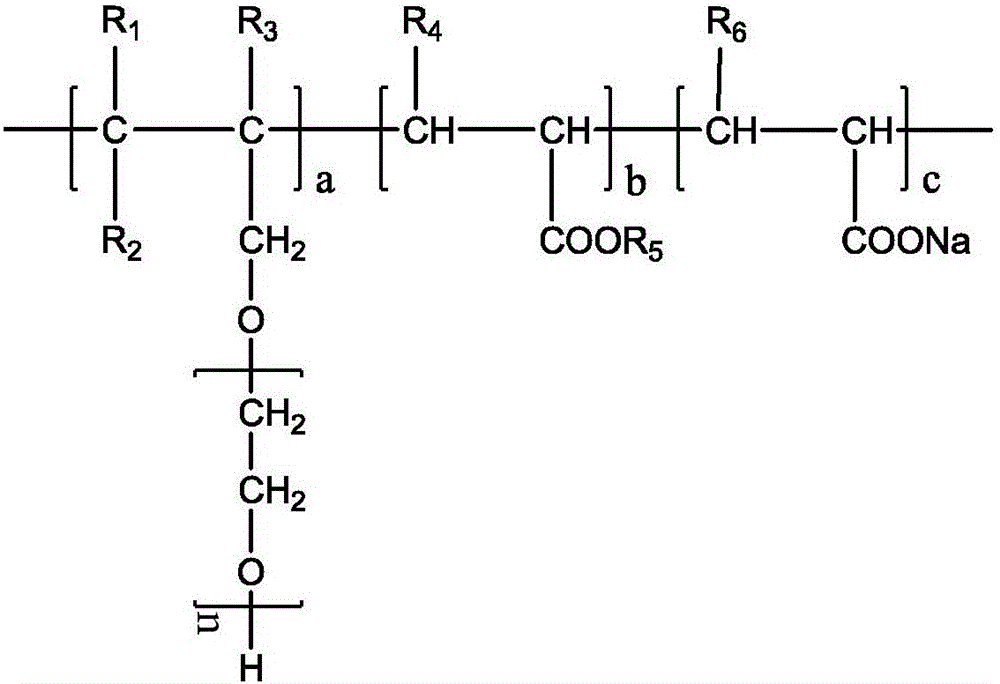

Low-sensitive type polycarboxylic acid slump retaining agent and preparation method thereof

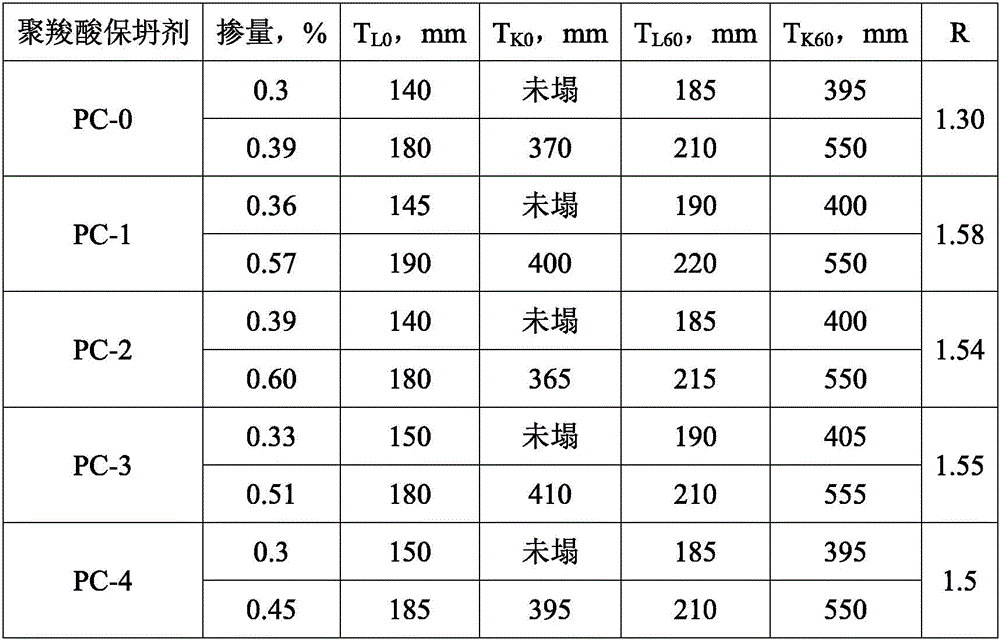

The technology of a type of polycarboxylic acid and slump retention agent is applied in the field of low-sensitivity polycarboxylic acid slump retention agent and its preparation, which can solve the problems of bleeding or segregation, inconvenient use of commercial concrete, and excessive loss of concrete over time. To achieve the effect of improving dosage sensitivity, wide molecular distribution and reducing activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

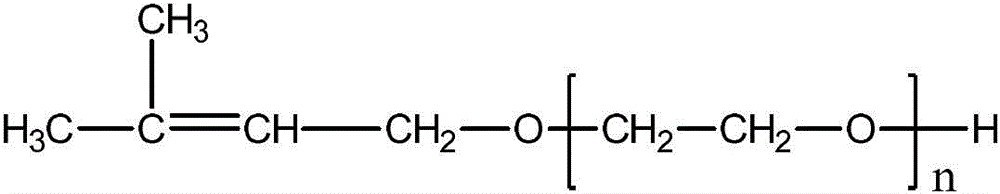

[0027] Get 85 parts of monomer prenol polyoxyethylene ether (TPEG) (molecular weight: 2400) and 100 parts of water into the reaction container, stir until the monomer is completely dissolved, and drop A, B, C, D four kinds of solution, A, B, D solution dropwise time is 1.5h, C solution dropwise time is 1.6h, reaction temperature is controlled at 10 ~ 45 ℃, keep warm for 1h after dropwise addition, add NaOH solution to adjust the pH to 5 , replenishing water so that the solid content of the reaction solution is reduced to 40%, to obtain the low-sensitivity polycarboxylate slump-retaining agent;

[0028] Among them, A solution is: take 3.3 parts of acrylic acid, 1 part of sodium acrylate and 9 parts of hydroxyethyl acrylate, dissolve them in 10 parts of water, and obtain A solution;

[0029] B solution is: take 0.5 parts of hydrogen peroxide and dissolve in 10 parts of water to obtain B solution;

[0030] C solution is: take 0.3 parts of ascorbic acid and dissolve in 10 parts o...

Embodiment 2

[0035] Get 85 parts of monomer prenol polyoxyethylene ether (TPEG) (molecular weight: 2400) and 100 parts of water into the reaction container, stir until the monomer is completely dissolved, and drop A, B, C, D four kinds of solution, A, D solution dropwise time is 1h, B, C solution dropwise time is 1.2h, reaction temperature is controlled at 10~45 ℃, keep warm for 1h after dropwise addition, add NaOH solution to adjust pH to 5.5, Replenish water so that the solid content of the reaction solution is reduced to 40%, to obtain the low-sensitivity polycarboxylate slump-retaining agent;

[0036] Among them, the A solution is: take 3.3 parts of methacrylic acid, 1.6 parts of sodium methacrylate and 8 parts of hydroxypropyl acrylate, and dissolve them in 10 parts of water to obtain the A solution;

[0037] Solution B is: take 0.8 parts of hydrogen peroxide and dissolve in 10 parts of water to obtain solution B;

[0038] Solution C is: take 0.6 parts of diaobai and dissolve in 10 p...

Embodiment 3

[0041] Take 80 parts of monomer prenol polyoxyethylene ether (TPEG) (molecular weight: 2400) and 100 parts of water into the reaction container, stir until the monomer is completely dissolved, and drop A, B, C, D four kinds of solutions, A solution dripping time is 1h, B, C, D solution dripping time is 1.2h, the reaction temperature is controlled at 10 ~ 45 ℃, keep warm for 1h after dropping, add NaOH solution to adjust the pH to 5, Replenish water so that the solid content of the reaction solution is reduced to 40%, to obtain the low-sensitivity polycarboxylate slump-retaining agent;

[0042] Among them, the A solution is: take 5 parts of acrylic acid, 1.5 parts of sodium acrylate and 11.3 parts of hydroxyethyl acrylate, and dissolve them in 10 parts of water to obtain the A solution;

[0043] B solution is: take 0.9 parts of hydrogen peroxide and dissolve in 10 parts of water to obtain B solution;

[0044] Solution C is as follows: take 0.5 parts of diaobai and dissolve in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com