Methyl acetate production method

一种乙酸甲酯、酸性的技术,应用在生产乙酸甲酯及其衍生物领域,能够解决易失活、二甲醚羰基化活性低、不能够满足工业生产的需求等问题,达到稳定性提高、反应活性高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] The present invention is described in detail below through some examples, but the present invention is not limited to these examples.

[0031] In an embodiment, the conversion rate of dimethyl ether and the selectivity of methyl acetate are all calculated based on the number of carbon moles of dimethyl ether:

[0032] The conversion rate of dimethyl ether=[(the number of dimethyl ether carbon moles in the feed gas)-(the number of dimethyl ether carbon moles in the product)]÷(the number of dimethyl ether carbon moles in the feed gas)×(100% )

[0033] The selectivity of methyl acetate=(2 / 3)×(the number of carbon moles of methyl acetate in the product)÷[(the number of carbon moles of dimethyl ether in the feed gas)-(the number of moles of dimethyl ether in the product) ]×(100%)

[0034] The four Na-EMTs with silicon-aluminum atomic molar ratios of 2, 4, 15 and 25, and the Na-EMTs with a silicon-aluminum atomic molar ratio of 4 containing Ga and Fe in the framework were p...

preparation example

[0036] H-EMT catalyst

[0037] 100 grams of roasted Na-EMT zeolite molecular sieves with silicon-aluminum atomic molar ratios of 2, 4, 15 and 25 were exchanged three times with 0.5 mol / L ammonium nitrate, each time for 2 hours, washed with deionized water, and dried. Calcined at 550°C for 4 hours, and respectively prepared 20-40 mesh 1#, 2#, 3# and 4# catalysts by extrusion.

[0038] Ga-EMT catalyst

[0039] 100 g of calcined gallium-containing Na-EMT zeolite molecular sieves (silicon-aluminum atomic molar ratio of 4) were exchanged three times with 0.5 mol / L ammonium nitrate, each time for 2 hours, washed with deionized water, dried, and roasted at 550 ° C After 4 hours, 20-40 mesh 5# catalyst was prepared by extrusion.

[0040] Fe-EMT catalyst

[0041] 100 g of calcined iron-containing Na-EMT zeolite molecular sieve (silicon-aluminum atomic molar ratio is 4) was exchanged three times with 0.5 mol / L ammonium nitrate, each time for 2 hours, washed with deionized water, drie...

Embodiment 1

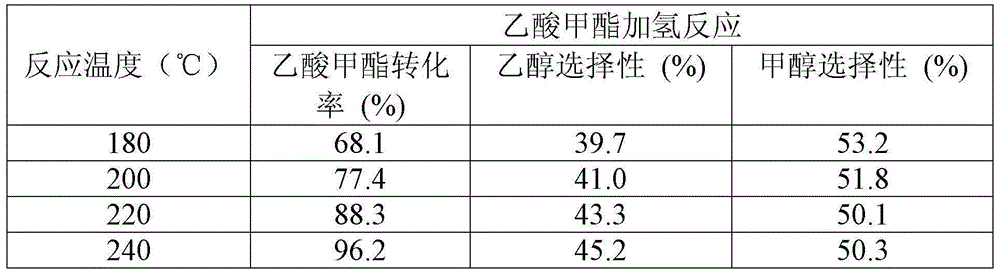

[0056] According to Table 2, put 10 g of catalyst into a fixed-bed reactor with a tube inner diameter of 28 mm, raise the temperature to 550 °C at 5 °C / min under a nitrogen atmosphere, keep it for 4 hours, and then drop it to a reaction temperature of 190 °C under a nitrogen atmosphere. °C, the pressure of the reaction system was raised to 5 MPa with CO. The reaction raw materials are passed through the catalyst bed from top to bottom. Among them, the dimethyl ether feed space velocity is 0.10h -1 The mol ratio of carbon monoxide and dimethyl ether is 6: 1, under the condition that the mol ratio of the carbon monoxide in the feed gas of carbon monoxide and hydrogen is 2: 1, under the condition of 190 ℃ of reaction temperature, catalytic reaction runs 100 hours, reaction The results are shown in Table 2.

[0057] Table 2 "Evaluation results of dimethyl ether carbonylation catalysts

[0058] catalyst Dimethyl ether conversion rate (%) Methyl acetate selectivity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com