Method for purification of hydrocyanic acid

A purification method, the technology of hydrocyanic acid, applied in the direction of cyanic acid/isocyanic acid, etc., can solve the problems of rectification tower clogging, lower operating degree, packing agglomeration, etc., to increase energy consumption, reduce energy consumption, and evenly distribute Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for purifying hydrocyanic acid, wherein, the structure of the production device used in the method for purifying is as attached to the description figure 1 As shown, the absorption tower 1 is provided with a spray liquid inlet pipeline, a hydrocyanic acid synthesis gas inlet pipeline and a tail gas pipeline; Along the direction from the stripping tower 2 to the absorption tower 1, a cold-heat heat exchanger 4 and a chilled water heat exchanger 5 are sequentially provided; the connection between the top of the stripping tower 2 and the bottom of the absorption tower 1 On the pipeline, a cold and hot heat exchanger 4 is connected; the reboiler 6 communicates with the stripping tower 2 through a circulation pipeline; the tower top of the stripping tower 2 communicates with the tower still of the rectifying tower 3; It is also communicated with circulation pump 7; circulation pump 7 is also communicated with outer circulation cooler 8; outer circulation cooler 8 is...

Embodiment 2-6

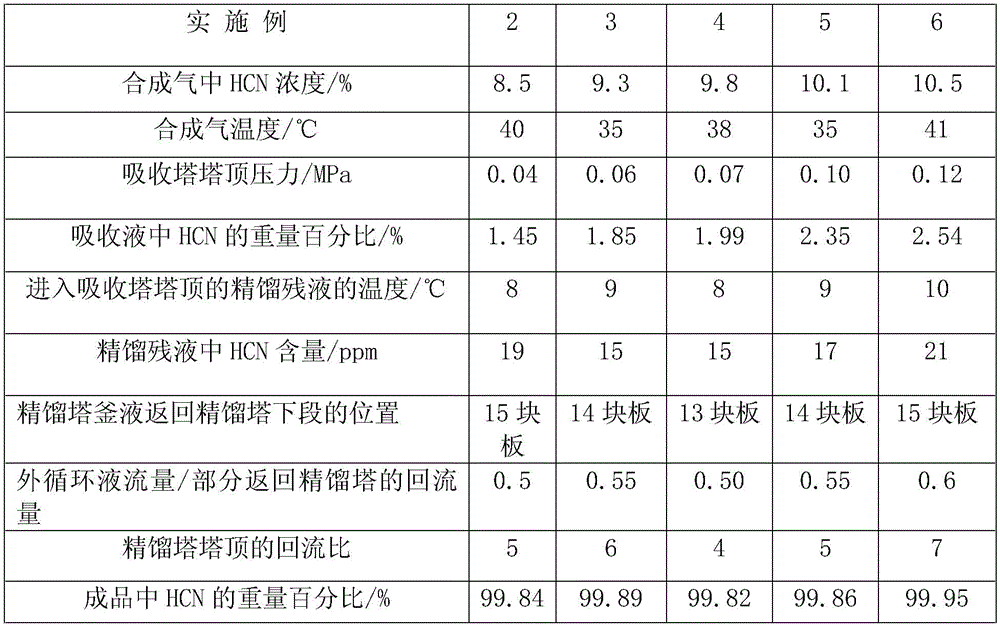

[0044] The structure and each equipment of the production device adopted in the embodiment 2-6 are all the same as the embodiment 1, and its preparation steps are also the same as the embodiment 1, the difference is only that different processing parameters are set in the embodiment 2-6, Carry out the rectifying purification process of hydrocyanic acid; Operating parameter and each detection data of setting among the embodiment 2-6 are shown in the following table 1:

[0045] Operating parameters and each detection data set in the embodiment 2-6 of table 1

[0046]

[0047] In addition, the present invention has also carried out the following operations as a comparative example, the structure of the production device adopted and each equipment are the same as in Example 1, and the various process parameters set in the preparation steps are also the same as in Example 1, The only difference is that in this comparative example, the circulation pump 7 and the external circulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com