System and method for three-way material distribution of belt conveyor

A technology of three-way distribution and three-way distribution device, which is applied in the direction of conveyor objects, transportation and packaging, etc., to achieve the effects of avoiding damage, ensuring reliability and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, taking the secondary lump ore system K115 to K109 and D116 three-way powder material system in the primary material yard of Meishan Iron and Steel Co., Ltd. as an example.

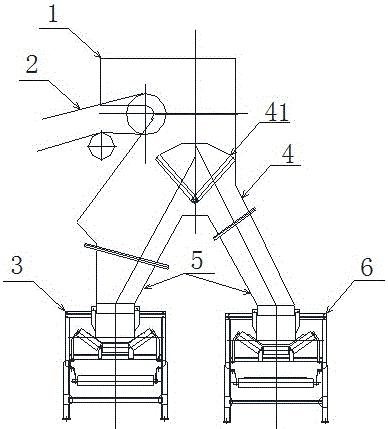

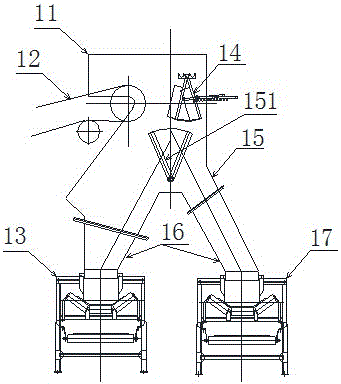

[0030] Such as figure 2 As shown, a belt conveyor three-way distribution system includes a casing 11, an upstream belt conveyor 12, a downstream belt conveyor II13, a diversion baffle 14, a three-way distributor 15, a chute 16, and a downstream belt conveyor I17, wherein three The feeder 15 is provided with a turning plate 151 . The flow guide baffle 14 is installed in the casing 11 , and the flow guide baffle 14 and the turnover plate 151 do not interfere with each other.

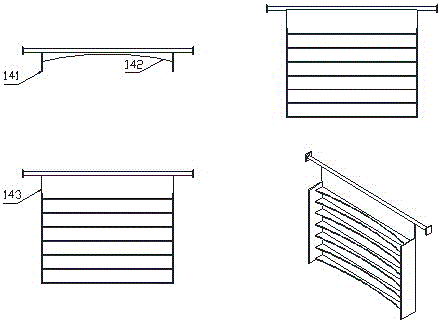

[0031] Such as image 3 As shown, the guide baffle 14 is equipped with a side baffle 141, a transverse baffle 142, and a bottom plate 143. The height of the side baffles 141 is large enough to avoid material skipping; the distance between the two side baffles 141 is smaller than the width of the flap 151; They...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com