High-precision ultra-large-stroke painting robot telescopic arm adopting statically indeterminate structure

A spraying robot, high-precision technology, applied in the field of robots, can solve problems such as high processing and assembly process requirements, difficulty in ensuring lateral rigidity, and impact on the accuracy of lifting frames, so as to reduce processing and assembly requirements and ensure smooth motion , the effect of improving stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

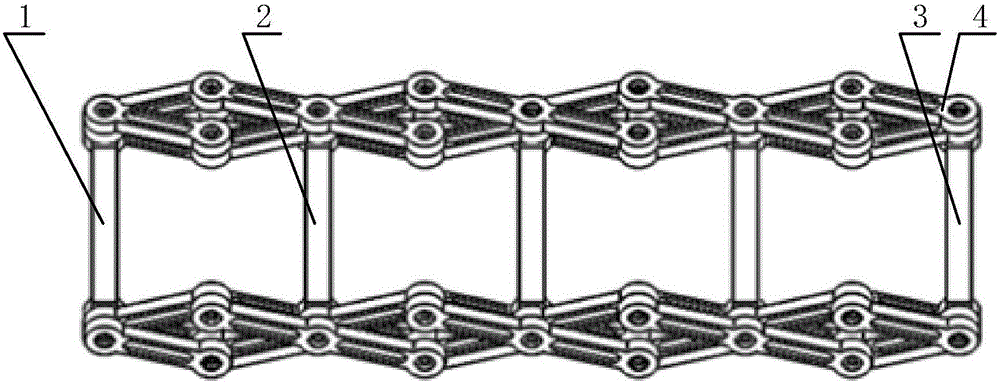

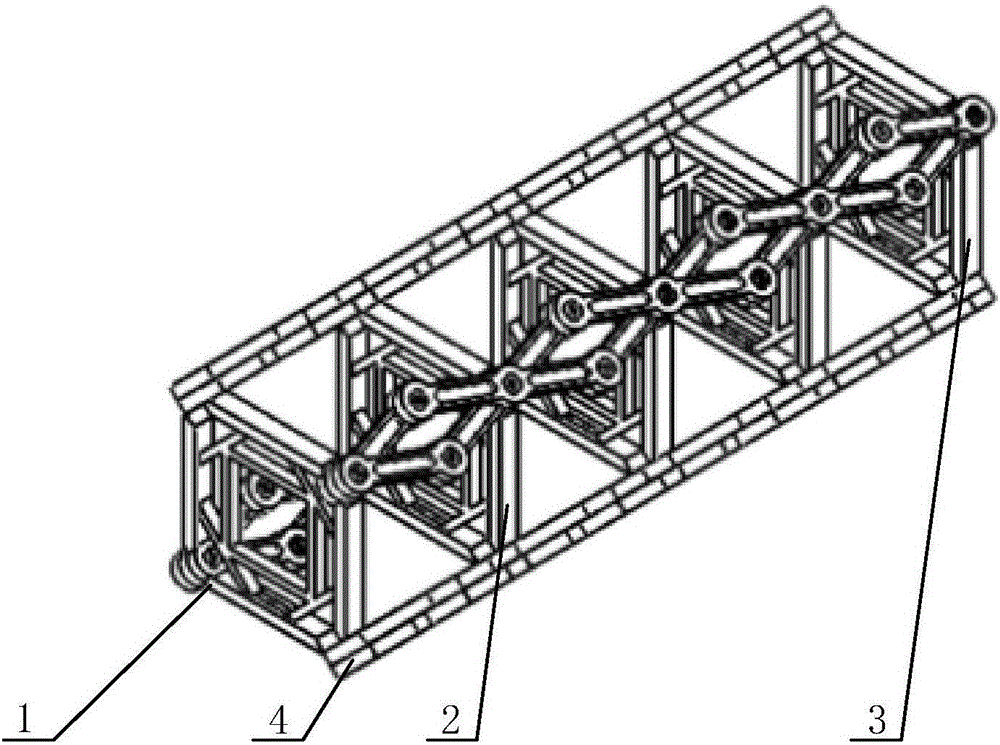

[0025] An embodiment of the present invention provides a telescopic arm of a high-precision super-large-stroke spraying robot with a super-statically indeterminate structure, see Figure 1-Figure 5 , including: a fixed base 1, a regular n-gon connection structure 2, an end workbench structure 3, and a multi-group scissors series mechanism 4.

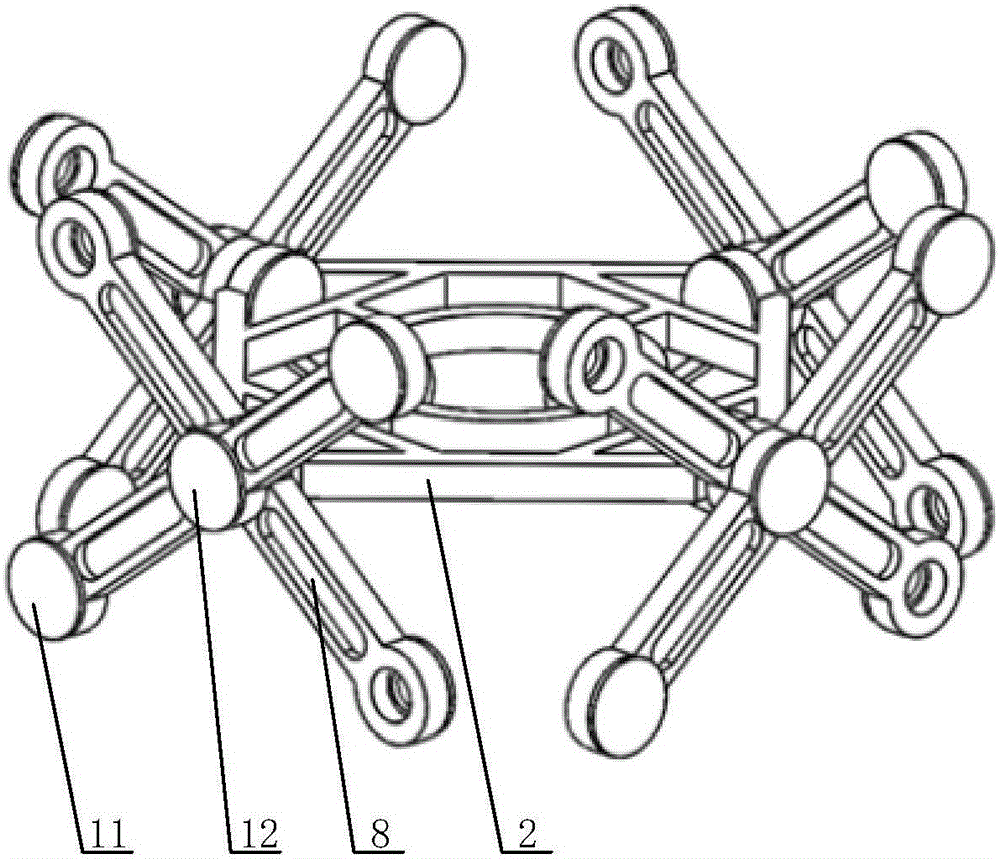

[0026] Among them, multiple sets of scissors series mechanisms 4 are respectively hinged with the fixed base 1 and the end table structure 3, and the end points of the regular n-gon connection structure 2 are hinged with multiple sets of scissors series mechanisms 4 respectively.

[0027] Each group of scissors series mechanisms 4 includes a long connecting rod 8 , a short connecting rod 7 , a to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com