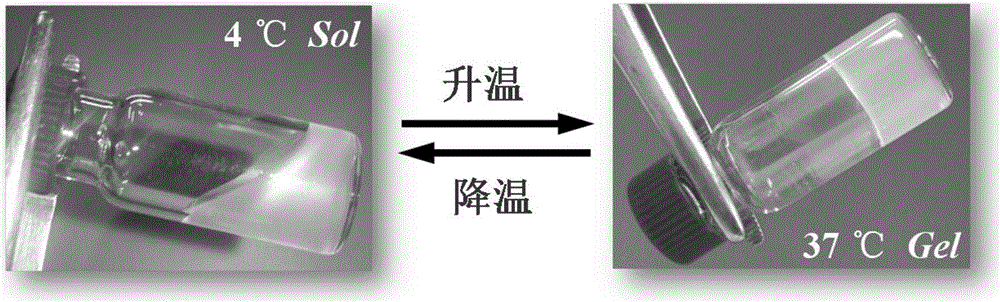

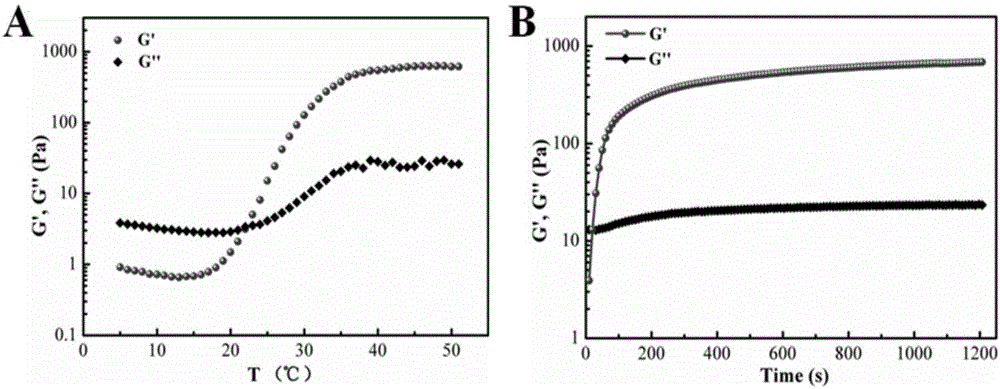

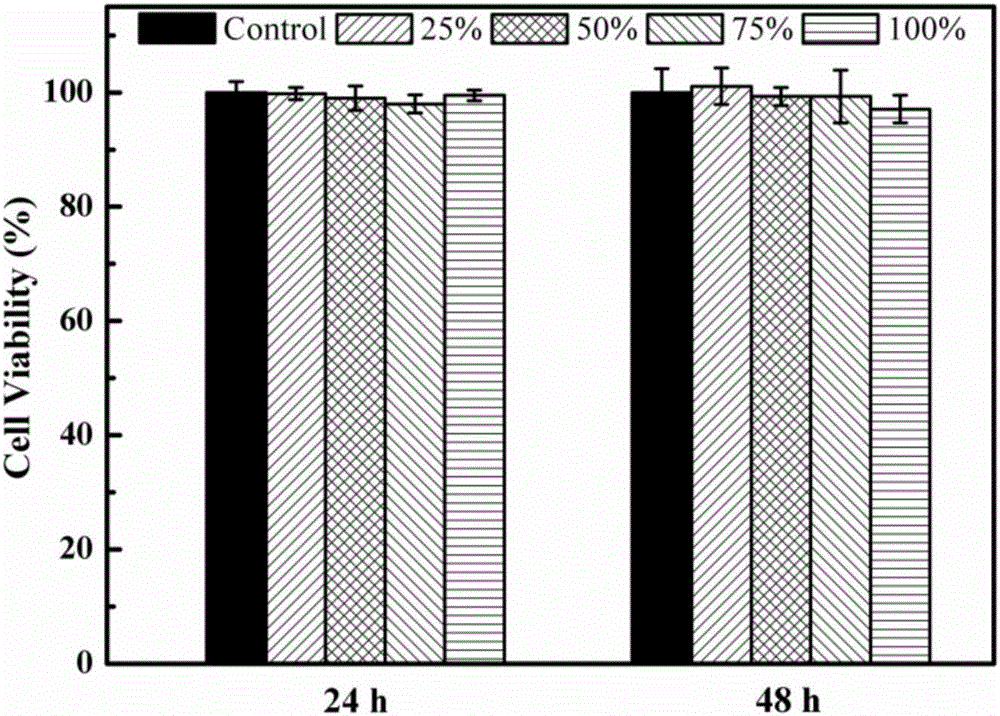

Temperature-sensitive injectable postoperative anti-adhesion material and preparation method thereof

An anti-adhesion and temperature-sensitive technology, which is applied in the fields of polymer materials and biomedical materials, can solve problems such as poor adhesion effect, hidden dangers of biological safety, and poor operation convenience, and achieve good biodegradability, process operation, and good integrity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Dissolve tamarind gum in deionized water at 25°C and stir for 12 hours to obtain a solution with a mass fraction of 1%;

[0032] (2) Centrifuge the solution obtained in step (1) at a speed of 9000 rpm for 15 minutes, and then drop the supernatant obtained from the centrifugation into anhydrous ethanol whose volume is 3 times its volume to obtain the precipitation product xyloglucan sugar;

[0033] (3) freeze-drying the xyloglucan obtained in step (2) to obtain dried xyloglucan;

[0034] (4) Dissolve the xyloglucan obtained in step (3) in a sodium acetate buffer of pH 4.5, and then add β-galactosidase derived from Aspergillus oryzae to obtain a xyloglucan concentration of 2% ( g / mL), a solution with a β-galactosidase concentration of 0.1% (g / mL);

[0035] (5) The solution system obtained in step (4) was mechanically stirred and reacted at 50°C and 500rpm for 24 hours, and then heated to 100°C for 30 minutes to terminate the enzymatic hydrolysis reaction, and then the reacti...

Embodiment 2

[0039] (1) Dissolve tamarind gum in deionized water at 15°C and stir for 48 hours to obtain a solution with a mass fraction of 2%;

[0040] (2) Centrifuge the solution obtained in step (1) at 20000 rpm for 5 minutes, and then drop the supernatant obtained from the centrifugation into absolute ethanol with a volume 10 times its volume to obtain the precipitated xyloglucan sugar;

[0041] (3) Dry the xyloglucan obtained in step (2) at a constant temperature and vacuum at a temperature of 25°C to obtain a dried xyloglucan;

[0042] (4) Dissolve the xyloglucan obtained in step (3) in sodium acetate buffer of pH 3.5, and then add β-galactosidase derived from Aspergillus oryzae to obtain a xyloglucan concentration of 3% ( g / mL), a solution with a β-galactosidase concentration of 0.15% (g / mL);

[0043] (5) The solution system obtained in step (4) was mechanically stirred and reacted at 50°C and 100rpm for 48 hours, then heated to 120°C for 15 minutes to terminate the enzymatic hydrolysis re...

Embodiment 3

[0047] (1) Dissolve tamarind gum in deionized water at 70°C and stir for 4 hours to obtain a solution with a mass fraction of 1.5%;

[0048] (2) Centrifuge the solution obtained in step (1) at 1000 rpm for 30 minutes, and then drop the supernatant obtained from the centrifugation into anhydrous ethanol twice its volume to obtain the precipitation product xyloglucan sugar;

[0049] (3) Drying the xyloglucan obtained in step (2) at a constant temperature and vacuum at a temperature of 80° C. to obtain dried xyloglucan;

[0050] (4) Dissolve the xyloglucan obtained in step (3) in a sodium acetate buffer of pH 5.5, and add β-galactosidase derived from Aspergillus niger to obtain a xyloglucan concentration of 1% ( g / mL), a solution with a β-galactosidase concentration of 0.05% (g / mL);

[0051] (5) The solution system obtained in step (4) was mechanically stirred and reacted at 50°C and 1000rpm for 12 hours, then heated to 150°C for 10 minutes to terminate the enzymatic hydrolysis reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com