Preparation technology of wall-breaking decoction piece

A technology of broken-wall decoction pieces and preparation process, which is applied in the direction of non-active ingredient medical preparations, medical preparations containing active ingredients, plant raw materials, etc., which can solve the problems of rapid dissolution of unfavorable medicinal active ingredients, inability to form ultrafine powder, and poor stability and other problems to achieve the effect of avoiding screen blockage, moderate tightness and good formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

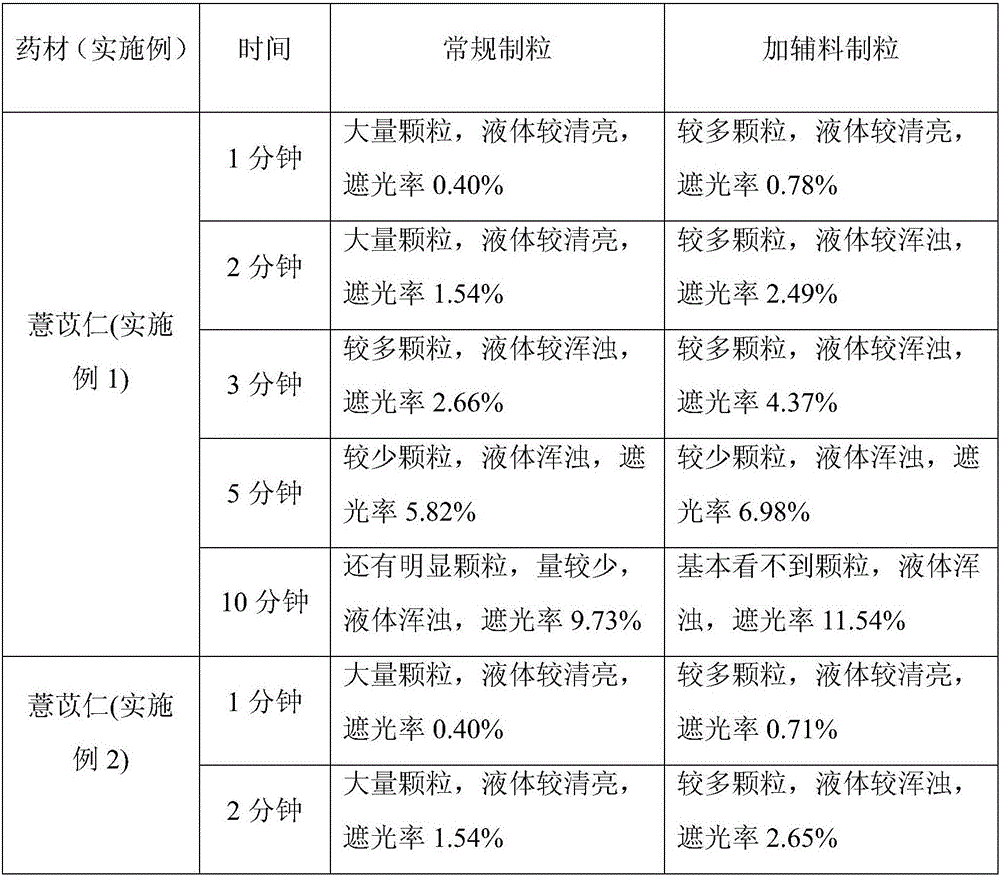

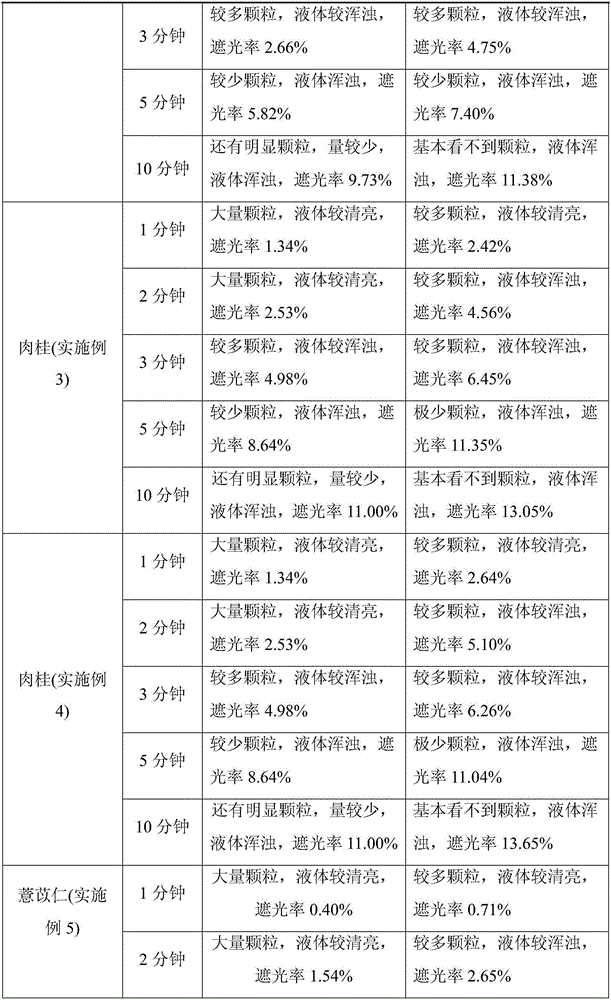

Examples

Embodiment 1

[0036] Coix Seed Broken Wall Decoction Pieces

[0037] 1) Medicinal material processing: the coix seed medicinal material is sorted, cleaned, dried, sliced, and coarsely crushed to about 100 mesh;

[0038] 2) Intermittent sterilization: Coix seed coarse powder is placed in a constant temperature and humidity box with a thickness of about 10mm, set at a temperature of 65°C (the actual temperature is 60-70°C), and kept dry and sterilized for 8 hours; The powder is maintained at a temperature of 25°C and a relative humidity of 75% for 12 hours; then the temperature of the constant temperature and humidity box is adjusted to 35°C and the relative humidity is 88% for 24 hours; 30mm, set the temperature at 75°C (the actual temperature is 70-80°C), keep it dry and sterilized for 4 hours; routinely detect the microorganisms in the coarse powder of medicinal materials, and obtain the coarse powder of coix seed that meets the microbial limit requirements for direct consumption of decoctio...

Embodiment 2

[0044] Coix Seed Broken Wall Decoction Pieces

[0045] 1) Medicinal material processing: the coix seed medicinal material is sorted, cleaned, dried, sliced, and coarsely crushed to about 100 mesh;

[0046] 2) Bacteria-killing process: Coix seed coarse powder is placed in a constant temperature and humidity box with a thickness of about 5mm, set at a temperature of 70°C (the actual temperature is 65-75°C), and kept dry and sterilized for 4 hours; The powder is maintained at a temperature of 20°C and a relative humidity of 70% for 15 hours; then the temperature of the constant temperature and humidity box is adjusted to 33°C and the relative humidity is 83% for 8 hours; 20mm, set the temperature at 65°C (the actual temperature is 60-70°C), keep it dry and sterilized for 6 hours; repeat the steps of dormant body growth-killing the vegetative body once again, and routinely detect the microorganisms in the coarse powder of medicinal materials; Directly take Coix seed coarse powder...

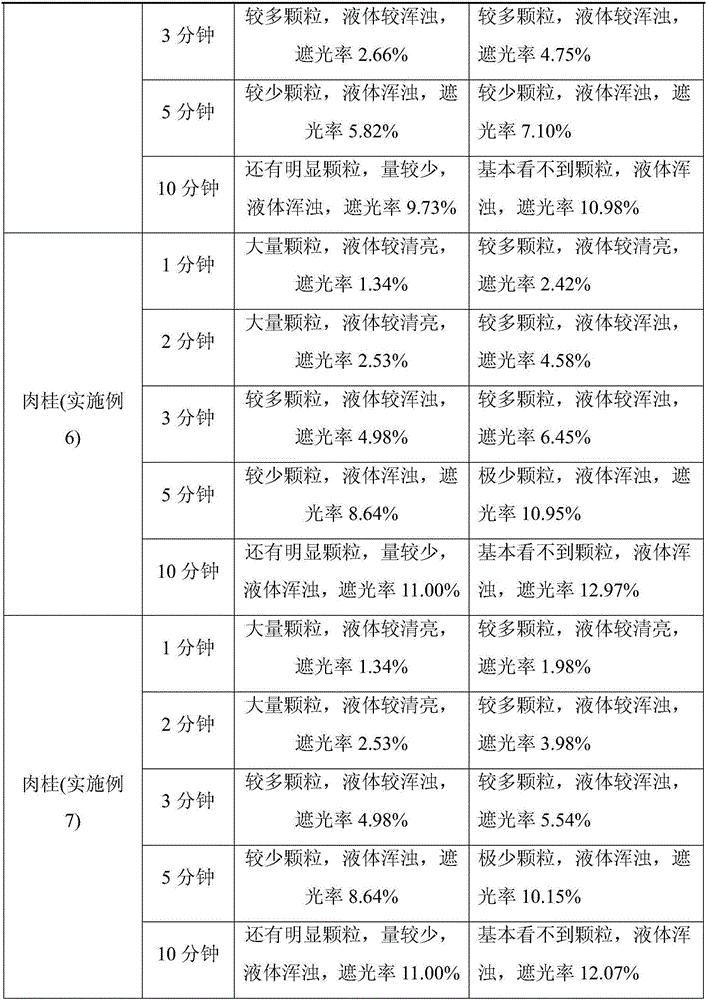

Embodiment 3

[0052] Cinnamon Broken Drink Pieces

[0053] 1) Medicinal material processing: the cinnamon medicinal material is sorted, cleaned, dried, sliced, and coarsely crushed to about 100 mesh;

[0054] 2) Bacteria-killing process: Put the coarse cinnamon powder in a constant temperature and humidity box with a thickness of about 30mm, set the temperature at 75°C (the actual temperature is 70-80°C), and keep it dry and sterilized for 4 hours; the coarse powder of medicinal materials after treatment Maintain at a temperature of 25°C and a relative humidity of 75% for 24 hours; then adjust the temperature of the constant temperature and humidity box to 40°C and maintain a relative humidity of 80% for 12 hours; place the coarse powder of medicinal materials in a constant temperature and humidity box with a thickness of 10mm , set the temperature at 80°C (the actual temperature is 75-85°C), keep it dry and sterilized for 0.5h; repeat the steps 4 times, and routinely detect the microorgani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com