Battery cell gas production detection device and detection method

A detection device and cell technology, which is applied to measurement devices, sampling devices, and gas mixture analysis, etc., can solve problems such as the inability to reflect the gas production of cells, solve the actual gas production problem, improve authenticity, and ensure service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

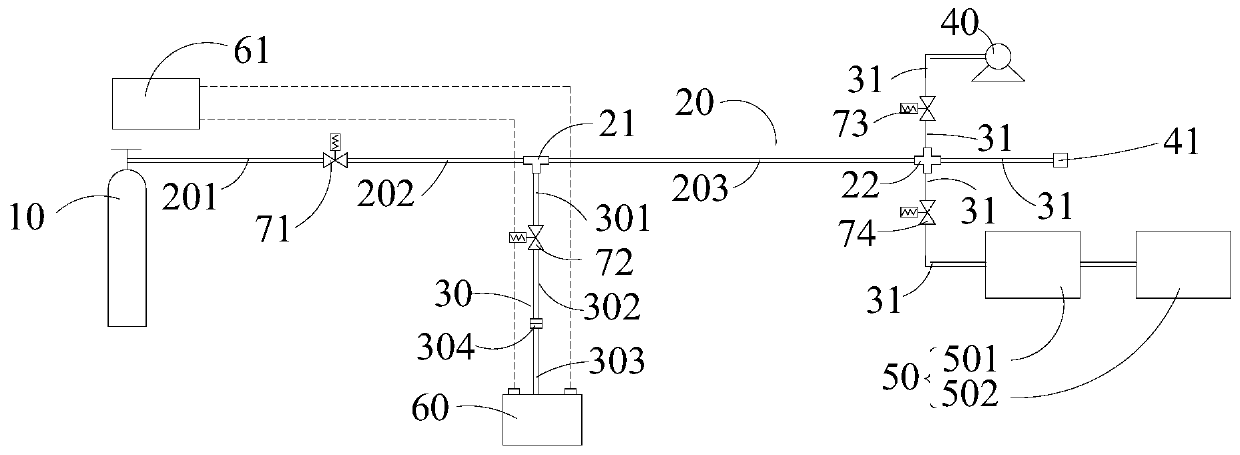

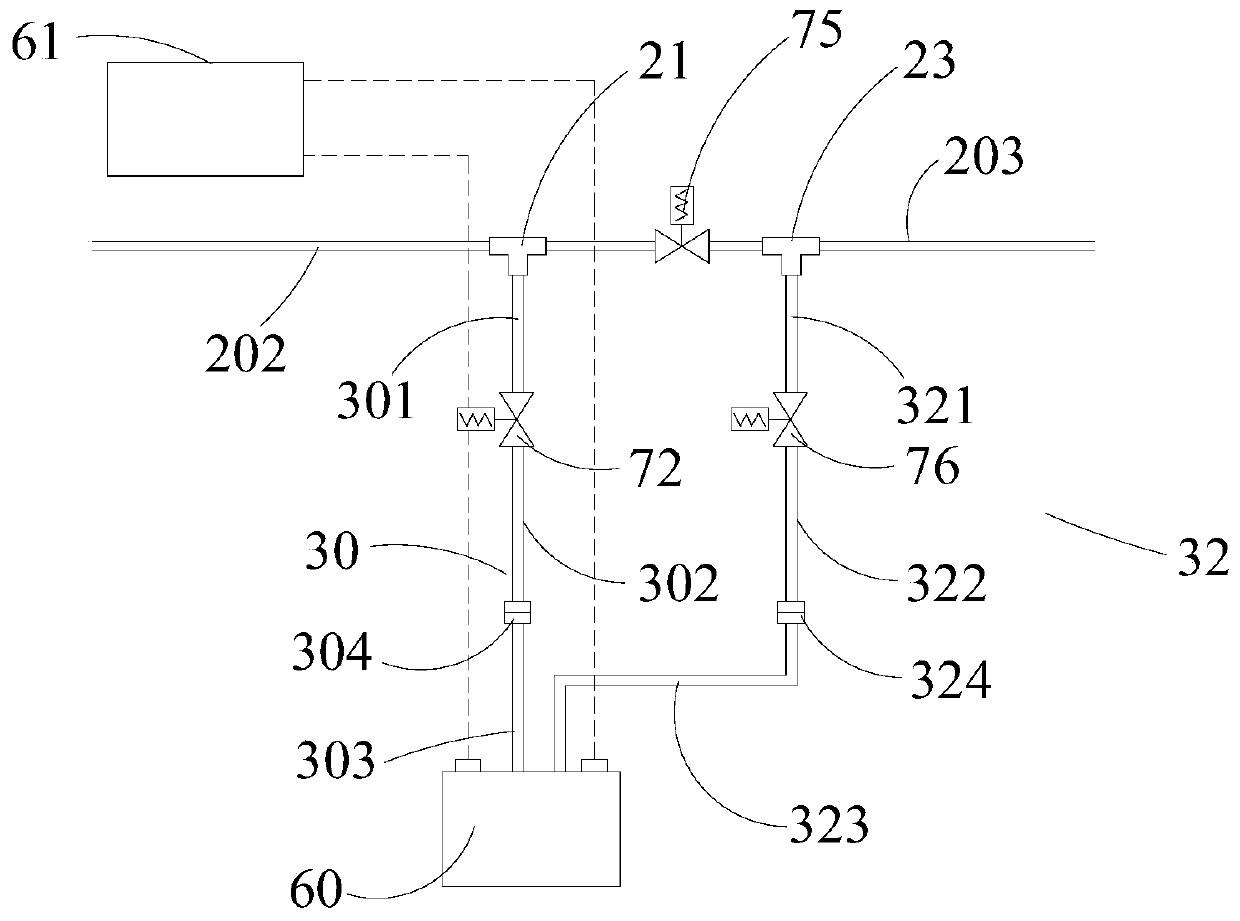

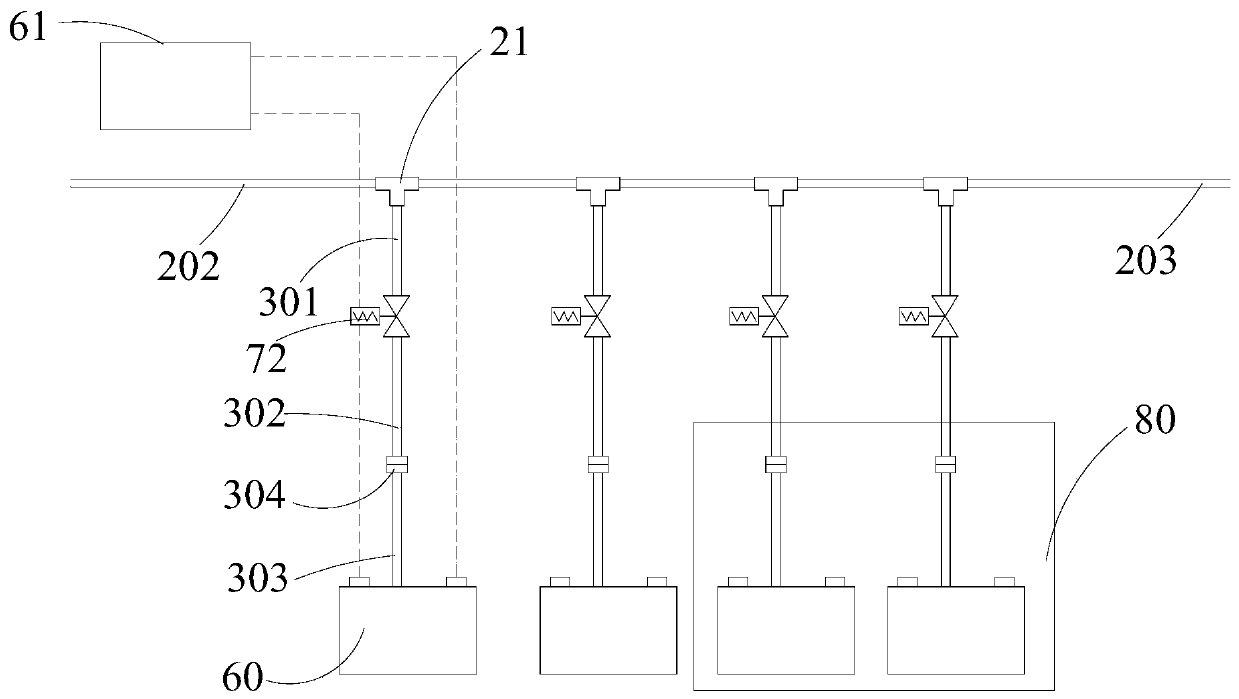

[0074] The first embodiment, such as figure 1 As shown, the cell gas production detection device includes a carrier gas bottle 10, a vacuum mechanism 40, a testing device 50, a first pipeline 20 and a second pipeline 30, and the two ends of the first pipeline 20 are respectively connected to the carrier gas bottle 10, The test equipment 50 is in communication, and the first pipeline 20 is provided with a first communication position; one end of the second pipeline 30 is in communication with the first liquid injection hole of the cell, usually through the first welding joint 304 to realize communication with the first liquid injection hole , and the other end communicates with the first pipeline 20 at the first communication position; the vacuum mechanism 40 is used to evacuate the first pipeline 20 and the second pipeline 30 .

[0075] Usually, at the first communication position, the first pipeline 20 and the second pipeline 30 communicate with each other through the first t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com