Diode bending, detecting and labeling device

A bending device and detection device technology, applied in the direction of measuring devices, optical testing flaws/defects, instruments, etc., can solve the problems that the bending angle cannot be completely consistent, the product qualification rate is not high, and the operation process is complicated, etc., to achieve bending Consistent bending angle, convenient operation and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The process of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

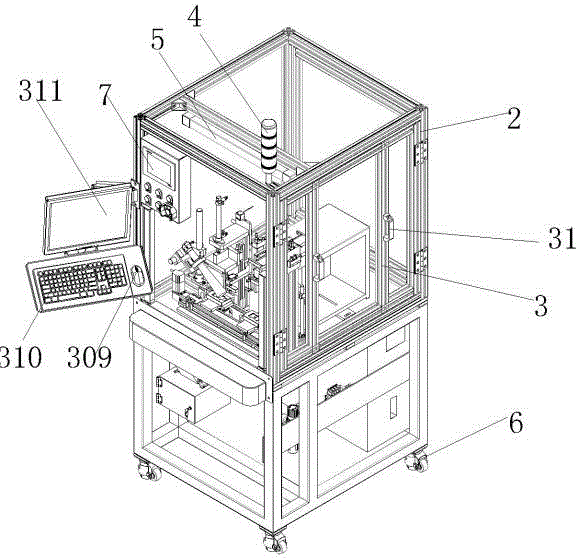

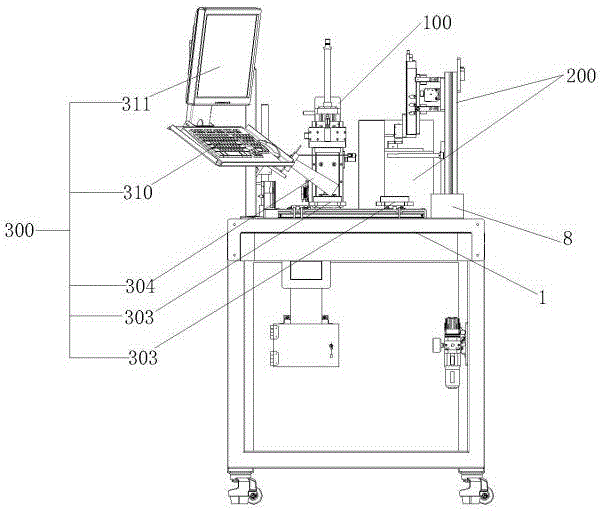

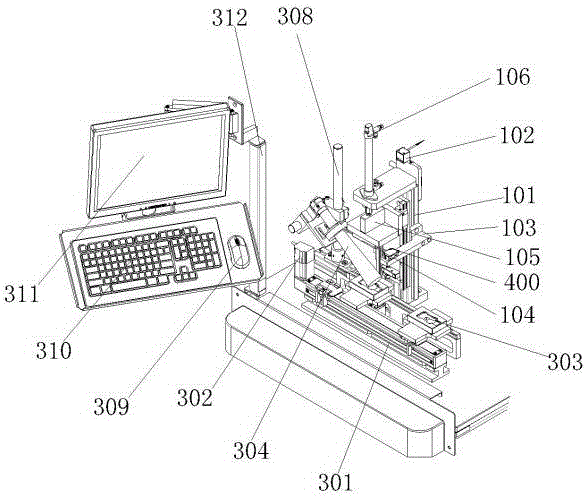

[0018] As shown in the figure, a diode bending detection and labeling device includes a workbench 1, an instrument rack 312 is arranged on the workbench 1, and a controller 7 for controlling the operation of the entire device is installed on the instrument rack 312; A transparent cover 2 is also installed on the workbench 1 . An illuminating device 5 is installed on the inner top end of the transparent outer cover 2 for lighting, and a tower light 4 is also arranged on the outer upper end of the transparent outer cover 2 . The side of the transparent cover 2 corresponding to the labeling machine 200 is provided with a movable window 3 , and the movable window 3 is provided with a window handle 31 . Opening the movable window 3 can deliver the products after the bending detection and labeling process is completed. The bottom of the workb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com