Strip folding machine special for resistor

A folding machine and resistor technology, applied in the field of resistors, can solve problems such as resistor damage, balance fulcrum tilting, resistor falling off, etc., to achieve the effect of ensuring angle, avoiding tilt, and improving firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] as attached figure 1 To attach Image 6 Shown:

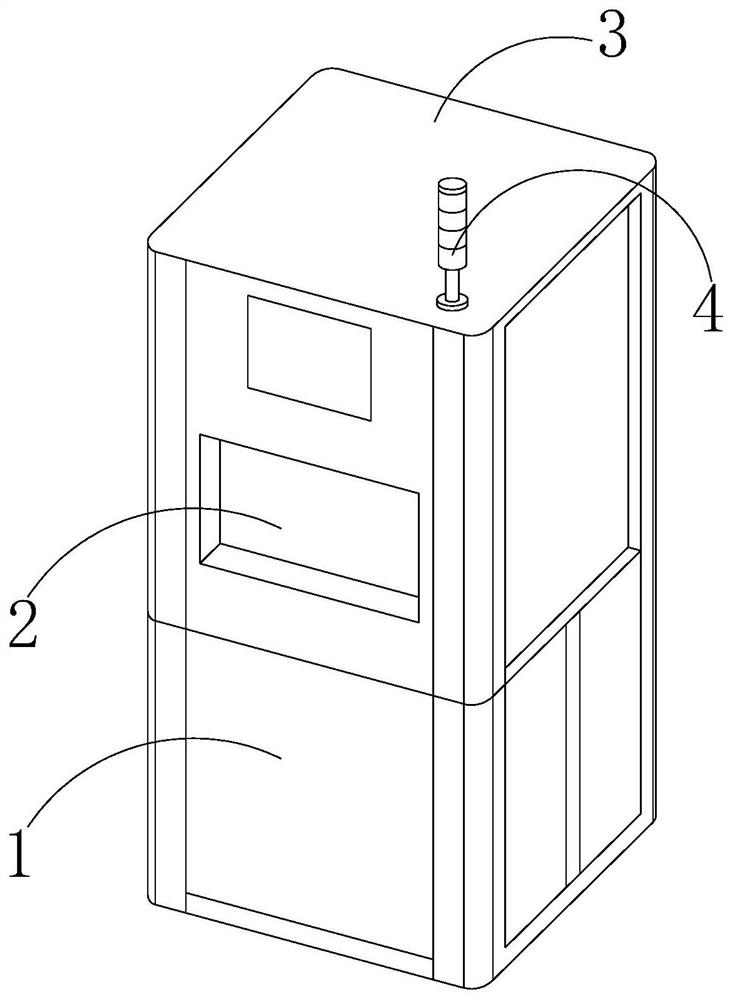

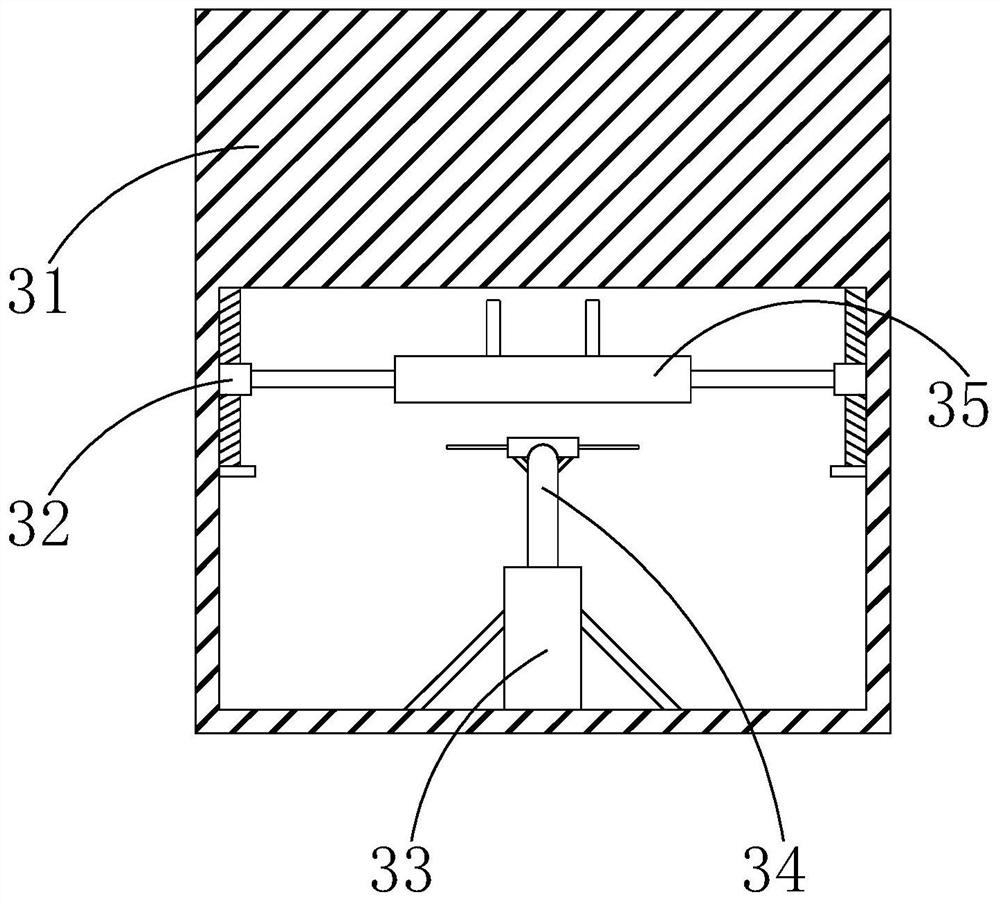

[0025] The present invention is a special folding machine for resistors. Its structure includes a support base 1, a window 2, a folding main body 3, and a warning light 4. The upper end of the supporting base 1 is fixed to the bottom of the folding main body 3, and the folding main body 3 The front end surface is embedded with a window 2, and the top of the folded bar host 3 is provided with a warning light 4, and the folded bar host 3 includes a host shell 31, a screw rod 32, a base 33, a supporting mechanism 34, and a bending mechanism 35. The bottom of the host housing 31 is fixed to the top of the support base 1, and the upper end of the host housing 31 is provided with a screw rod 32, and the screw rod 32 is fixed to the outer end of the bending mechanism 35, and the bottom of the base 33 is fixed on the host housing 31 inner bottom, the top of the base 33 is provided with a supporting mechanism 34, and the support...

Embodiment 2

[0033] as attached Figure 7 to attach Figure 8 Shown:

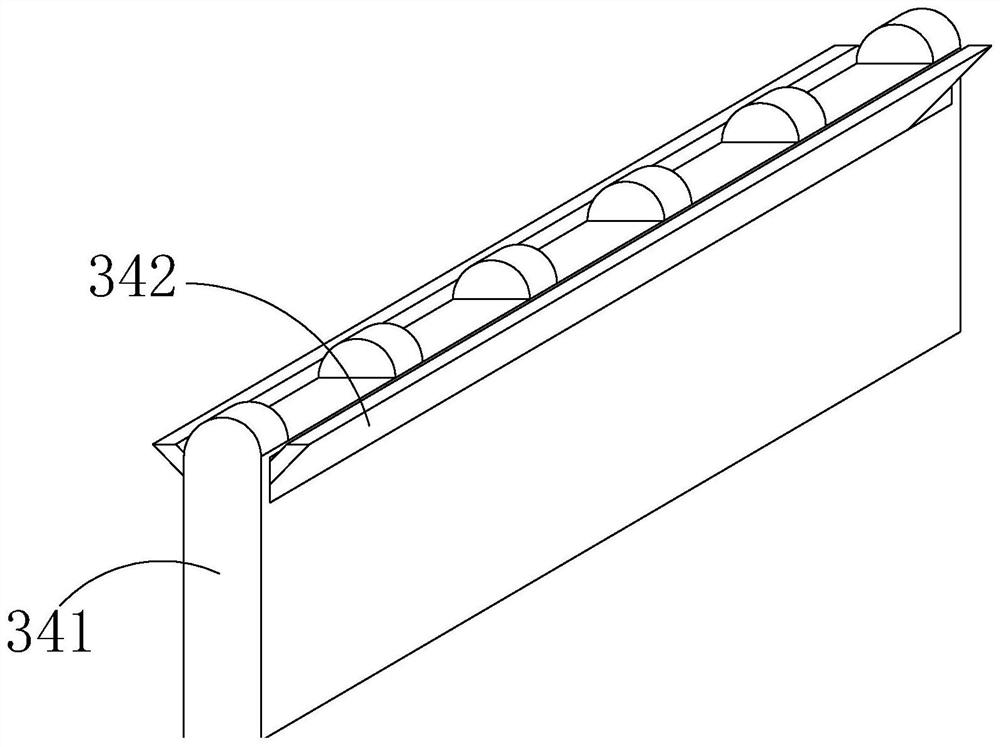

[0034] Wherein, the bending mechanism 35 includes a support arm 351, a bending frame 352, and a lifting mechanism 353. One end of the support arm 351 is fixed to the outside of the screw rod 32, and the other end of the support arm 351 is in contact with the surface of the bending frame 352. Welding, the middle part of the bending frame 352 is provided with a lifting mechanism 353, the middle part of the bending frame 352 is a cavity structure, and five lifting mechanisms 353 are equidistantly distributed on the middle cavity structure of the bending frame 352, Good for independent snubbing on top of the five resistors.

[0035] Wherein, the lifting mechanism 353 includes a guide frame 53a, a spring bar 53b, and a fitting plate 53c. The rod 53b runs through the inside of the outer end of the fitting plate 53c through a clearance fit. The fitting plate 53c is located in the middle of the bending frame 352. There are t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com