Front fork measuring instrument of tricycle

A measuring instrument and tricycle technology, applied in measuring devices, mechanical measuring devices, angle/taper measurement, etc., can solve the problems of unreliable front fork tube verticality, poor product consistency, and inaccurate measurement, etc., to achieve convenient and intuitive measurement Measurement, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

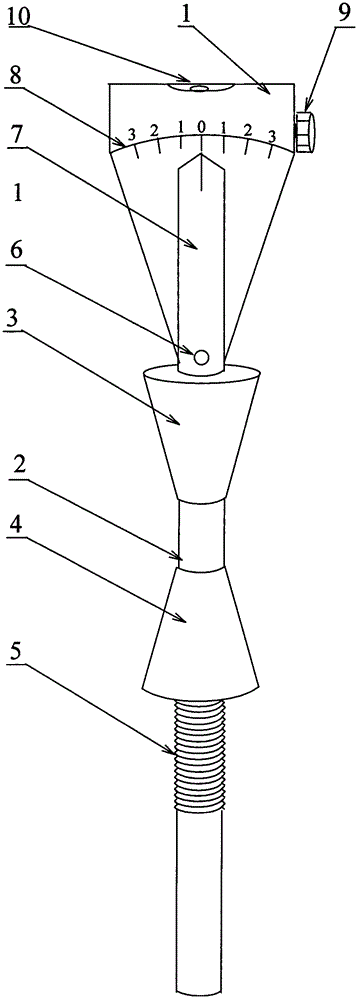

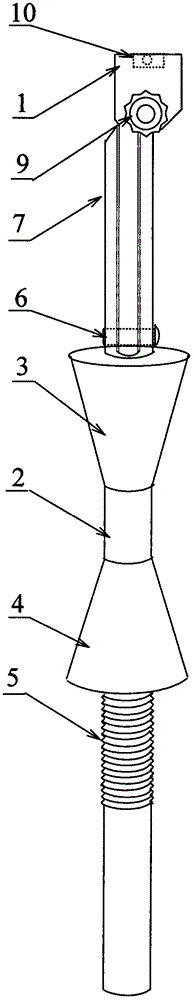

[0012] This patent includes in the accompanying drawings: it consists of a level meter measuring head (1), which is connected together with a measuring fixed shaft (2) through a connecting pin (6), wherein the lower end of the measuring fixed shaft (2) is threaded, and the measuring fixed shaft (2) The upper part fixes the upper tapered sleeve (3), and the thread on the lower end of the measuring fixed shaft (2) cooperates with the lower tapered sleeve (4) to fix the measuring instrument, so that the fixed shaft (2) is centered in the measuring fork tube, and the level is The upper end of the measuring head (1) is equipped with a bubble level (10), the outer end of the level measuring head (1), and the angle indicator line (7) outside the upper end of the measuring fixed shaft (2), corresponding to the angle ruler scale (8), The waist screw (11) closely cooperates with the toothed thread at the end of the measuring adjustment head (12), and the measuring fixed shaft (2), upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com